- Dec 6, 2020

- 8

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

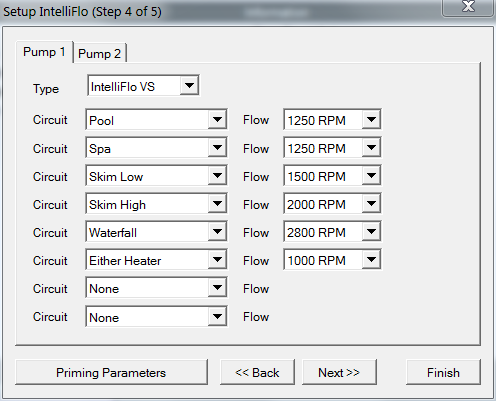

Hi, new to the forum and new pool owner. Just finished a build about 3 weeks ago. 18x34 pool with 7x7 spa. Intelliflo 3HP VSF pump, Pentair tagulus 100 with glass media filter and easy touch 8 system.

I've been waiting for over a week for the contractor to come by check things and still waiting.

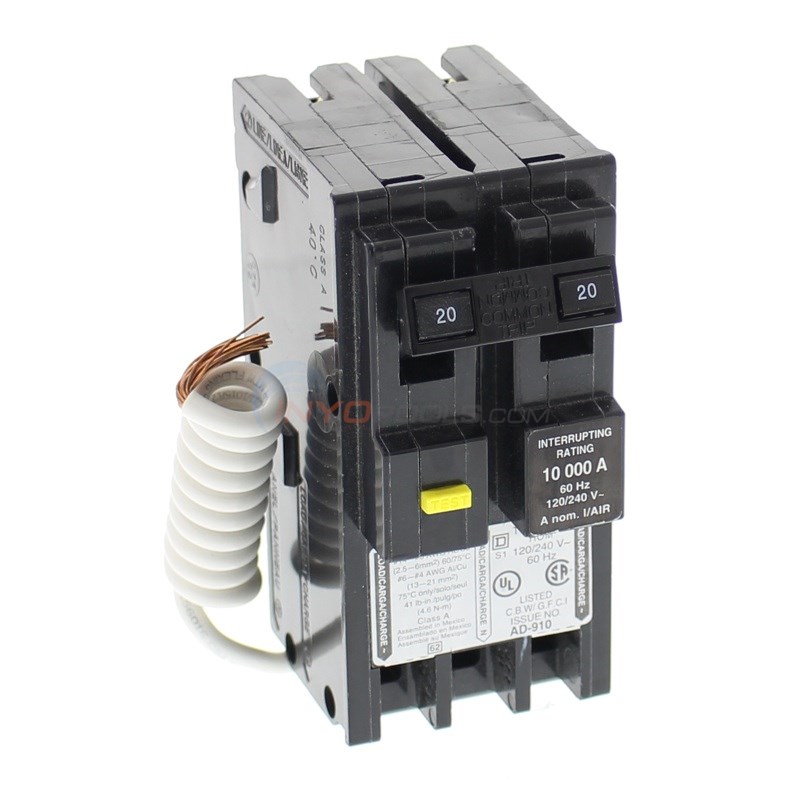

About a week ago I started getting alerts on the phone app with power outage alerts and communication lost together. About every third day I get a max pressure warning alert.

I've got the screenlogic software on my computer as well, but can't find a way to get more info about the alert like when it occurs to help diagnose what is going on.

Any thoughts on a cause?

Thanks

Mark

I've been waiting for over a week for the contractor to come by check things and still waiting.

About a week ago I started getting alerts on the phone app with power outage alerts and communication lost together. About every third day I get a max pressure warning alert.

I've got the screenlogic software on my computer as well, but can't find a way to get more info about the alert like when it occurs to help diagnose what is going on.

Any thoughts on a cause?

Thanks

Mark