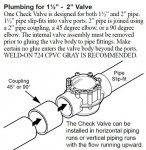

Hello all. Thank you guys for the storm advice. I’m sure there may be more damage to find once under pressure but the main visual damage i see here is this cracked valve.

Hoping I might be able to DIY but the proximity to the next valve has me concerned. Would love a recommendation about where to cut (or not if the valve could separated another way). Thank you!

Hoping I might be able to DIY but the proximity to the next valve has me concerned. Would love a recommendation about where to cut (or not if the valve could separated another way). Thank you!