- Jun 7, 2016

- 78

- Pool Size

- 32000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

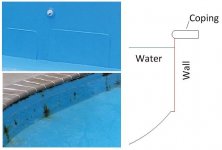

We have a Clayton Lambert pool that has stainless steel walls that were painted over a long time ago and the metal is deteriorating and bleeding through (see bottom left in the pic). We had a lot of work done on the pool last year and some of the bigger holes that were forming they covered with plexiglass sheets, then painted over all of it (see top left in the pic). You can barely see the glued-on sheets with the water in, and it worked great where covered, but other spots started bleeding through the new paint almost immediately. While not very appealing, if left, these will also form holes that will cause leaks over time.

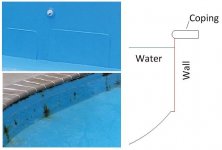

So... I am thinking about expanding this concept and covering the entire upper-wall (the stainless steel portion) in plexiglass. The right side of the image shows the basic profile of the pool walls; the coping hangs over, and then the wall is straight-down about 27 inches before hitting a small (~1") ridge where it turns into gunite and is curved down to the floor.

I can get custom-made 27" x 96" sheets of plexiglass (looking at 0.093" thick) that would sit on top of that ledge and come up just under the bottom side of the coping, covering the entire wall (highlighted in red in the profile picture). Cut out around the skimmers, jets, etc., cut sheets to fit side-by-side, use a heat gun to help bend around the corners (they are very rounded to begin with, plexiglass might be pliable enough to not even need to be heated), and glue them down with Permaseal caulk using a bead that covers the entire perimeter of the plexiglass as well as around any cutouts and some around the interior to help hold. Then get some Olympic Poxolon 2 Bikini Blue paint (matches what was used to repaint last year) and paint over all of the plexiglass walls.

Basically, it'd be an all new wall made of plexiglass with sheets end-to-end and slightly heated together to minimize seems. You can barely tell the individual sheets that are glued in now with the water filled, so even less if all that exists are seams between 8' sheets. Thin enough you can still unscrew jets, painted to match the rest of the pool, should minimize any further deterioration of the stainless steel walls as the Permaseal caulk around the entire parameterize of each sheet right to the edge should virtually waterproof the current wall and should last for quite a while.

Looking at materials & cost; these should give me a little extra of each to cover 27" height and approximately 135' of wall perimeter:

(19) Sheets of 27" x 96" x 0.093" acrylic Plexiglass = $1150

(14) Tubes of Olympic Permaseal = $325

(3) Gallons of Olympic Poxolon 2 Epoxy Paint = $340

Total = $1815 + rollers & other random material = $2000

Any thoughts/concerns/suggestions?

My main two concerns are:

1) Am I going to be able to get the current sheets of plexiglass off so that I don't have to cut around them when putting the new stuff on (pretty sure they're thicker than I was planning as well)

2) Best option to get leverage to install them without drilling into the pool gunite and building scaffolding in the pool that I can stand on (especially the deep end)

So... I am thinking about expanding this concept and covering the entire upper-wall (the stainless steel portion) in plexiglass. The right side of the image shows the basic profile of the pool walls; the coping hangs over, and then the wall is straight-down about 27 inches before hitting a small (~1") ridge where it turns into gunite and is curved down to the floor.

I can get custom-made 27" x 96" sheets of plexiglass (looking at 0.093" thick) that would sit on top of that ledge and come up just under the bottom side of the coping, covering the entire wall (highlighted in red in the profile picture). Cut out around the skimmers, jets, etc., cut sheets to fit side-by-side, use a heat gun to help bend around the corners (they are very rounded to begin with, plexiglass might be pliable enough to not even need to be heated), and glue them down with Permaseal caulk using a bead that covers the entire perimeter of the plexiglass as well as around any cutouts and some around the interior to help hold. Then get some Olympic Poxolon 2 Bikini Blue paint (matches what was used to repaint last year) and paint over all of the plexiglass walls.

Basically, it'd be an all new wall made of plexiglass with sheets end-to-end and slightly heated together to minimize seems. You can barely tell the individual sheets that are glued in now with the water filled, so even less if all that exists are seams between 8' sheets. Thin enough you can still unscrew jets, painted to match the rest of the pool, should minimize any further deterioration of the stainless steel walls as the Permaseal caulk around the entire parameterize of each sheet right to the edge should virtually waterproof the current wall and should last for quite a while.

Looking at materials & cost; these should give me a little extra of each to cover 27" height and approximately 135' of wall perimeter:

(19) Sheets of 27" x 96" x 0.093" acrylic Plexiglass = $1150

(14) Tubes of Olympic Permaseal = $325

(3) Gallons of Olympic Poxolon 2 Epoxy Paint = $340

Total = $1815 + rollers & other random material = $2000

Any thoughts/concerns/suggestions?

My main two concerns are:

1) Am I going to be able to get the current sheets of plexiglass off so that I don't have to cut around them when putting the new stuff on (pretty sure they're thicker than I was planning as well)

2) Best option to get leverage to install them without drilling into the pool gunite and building scaffolding in the pool that I can stand on (especially the deep end)