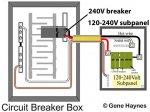

Just hunches, hard to know for sure from a pic:

1. What is that brown filament draped across the box? Is that metal? That's a little too close to those two 240V tabs for my liking, close to the breaker connectors, too. Sloppy, whatever it is. Even if it's some sort of non-conductive twine, it shouldn't be there.

2. It appears the main feed has three lines. The two 240 legs and a third, which looks to be a neutral. That heads into a taped blob, probably a connector or splice, maybe because there was not enough wire to connect it properly to the neutral bar. Not ideal. Probably not code.

3. The wire that appears to be connecting that blob to the neutral bar looks to be one or two gauges smaller than the wire coming up out of the conduit. Also not ideal. Probably not code.

4. If you look just above the tape blob, there is a white 12 gauge wire that appears to have a knick in it. Could be just a smudge, but looks just like a knick.

5. It looks like there are 12 gauge wires connecting to 15 amp breakers. Normally that's 14 gauge. This is not an inherent danger, but not good practice. See below.

6. It looks like there is a white wire attached to one of the breakers. Also not good practice:

Most of these things are not any immediate threat. Just bad practice, with potential problems baked in. A good electrical job is not only executed so that everything works fine, but also so the next electrician that comes along can rely on industry standard methods. Which is the purpose of building codes. For example: a 12 gauge white wire connected to a 15 amp breaker is perfectly safe, in and of itself. But somewhere else in your system that white wire emerges in a box. Some other person (besides the original electrician) should be able to reasonably assume that that 12 gauge white wire is the neutral wire of a 20 amp circuit, when in fact it is the hot wire of a 15 amp circuit. Similar for the 12 gauge black wire connected to a 15 amp breaker. At the other end, someone might wire up a circuit that requires 20 amps, relying on finding a black 12 gauge wire, when in fact there is only a 15 amp breaker protecting it. Codes exist to not only ensure everything works as intended, but also to protect future expansion and repairs...

I think even labeling breakers is code, so the fact that you don't know what a 60amp circuit is doing (or not doing) is another example of sloppy work (so seven)!

Plus, I'm not seeing a ground wire of sufficient gauge. I can't now remember if a sub panel is

not supposed to have a ground wire to the main breaker box, or

is supposed to have one. So I can't speak to that, other than that's something to check on. If I remember right, it's not optional, it's supposed to be one way or the other.

Whoever wired that box was likely not a licensed electrician, and it was not likely inspected.

arriving in next couple weeks so not the best time to start a big project, but after that craziness dies down I think I’ll give it a go. I’m sure I’ll ask for more advice when I do. Thanks again.

arriving in next couple weeks so not the best time to start a big project, but after that craziness dies down I think I’ll give it a go. I’m sure I’ll ask for more advice when I do. Thanks again.