Fixed it. Thanks to

ajw22 for the answer on how to do it in IC software.

Answer to "why the low speed?": For winter spa operation. I can't let my spa go below 68 deg per Pentair due to condensate issues, but I don't need to run it at 1800 rpm more than 12 hours/day for filtration/chlorination. Actual speed isn't really important as I'd rather have the pump off at night, but since I need flow for the temp sensor, I figured to have it at lowest speed allowable until heat is called for. At present I have it set to 1200 rpm for night operation. I want the speed low at night because the equipment pad is 2 feet from my bed and I like it quiet (preferably silent). I must have a suction leak because I tried running it at 450 rpm one night and in the morning I found the basket basically empty. It seems 1200 rpm is the lowest I can run it to prevent this cavitation.

More to the story:

I found that I was on the Fireman's switch for both my heaters on a i10D (dual bodies) setup. I wanted RS-485 but ran into issues which I was able to figure out:

- I used the existing 2-wire cable...didn't need the black wire for RS-485.

- I connected the heaters to J4 and J5 on the IC, doubling up some existing connections there. It doesn't matter which heater goes to which.

- I needed to set the 2nd heater to address 2 and left the pool heater on its default address 1. You can only do this at the heater panel and when the heater is not under IC control (eg use service mode, turn off IC, or otherwise disconnect it from RS-485).

- It was misleading in the manual to not clearly differentiate between 3-wire and RS-485. So I was confused since the RS-485 in the manual uses "3 wires". So I had the jumper on the heater's PCB on "3 wire". This is incorrect. That jumper should remain undisturbed and set on 2-wire. There are the 3 ways to set up a mastertemp in plain language:

a. 2-wire

b. 3-wire

c. RS-485

- Luckily my PB left the fireman's switch jumper wire in the box so I connected that, too.

- Had to delete both heaters in software because once established, they cannot be edited. Then I added both mastertemps using address 1 and 2 on "Other Equipment" page.

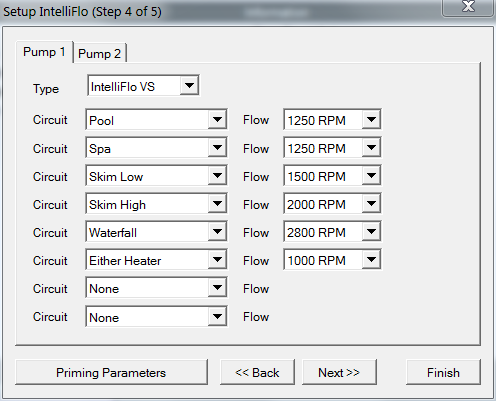

- on "pumps" page I then added "pool heater" to pool pump and "spa heater" to spa pump.

- in "general settings" I had to check "manual heat" to be able to alter heater temp during the schedule. I also checked "pumps on during heater cool-down delay" but I haven't verified if this actually works or not.

- on "schedules" I assigned heat source as mastertemp for spa and pool