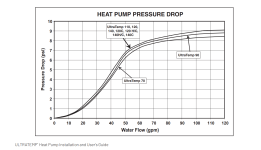

I recently installed a Crosswind V Heatpump, model 8550. I created a bypass so I can have water flowing around the heater. When I run my pump at 2500 rpm my filter pressure gauge reads 7 PSI (recirculate mode on multiport valve) and I see 60 gpm. I then turn my 3 way valve so water is routed fully through the heater and my pressure gauge jumps to 14 psi and my flow rate drops to 35 gpm.

It seems like any increase in pump speed above 20 gpm causes significant increase in pressure and drop in gpm.

Can anyone who has a crosswind v with a bypass share their filter pressure in bypass mode and in running through the heater mode?

I asked a friend who has a different brand heat pump and he said “needle barely moved, maybe 1 psi” so I am looking for a few additional data points.

And if anyone has seen something similar and has advice, I’d really appreciate it!!

It seems like any increase in pump speed above 20 gpm causes significant increase in pressure and drop in gpm.

Can anyone who has a crosswind v with a bypass share their filter pressure in bypass mode and in running through the heater mode?

I asked a friend who has a different brand heat pump and he said “needle barely moved, maybe 1 psi” so I am looking for a few additional data points.

And if anyone has seen something similar and has advice, I’d really appreciate it!!