Quick question that has been bugging me for years.

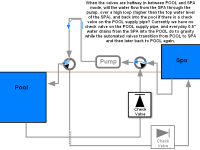

When the automated valves (via daily schedule) are in between transitioning from POOL and SPA mode (they take about 20-30 seconds to completely transition), will the water flow from the SPA through the pump, over a high loop (higher than the top water level of the SPA), and back into the pool if there is a check valve on the POOL supply pipe? Note, there is no overflow/waterfall from SPA to POOL. They are treated like different bodies of water, and the Jandy Iqualink controller switches between POOL and SPA once a day to generated chlorine and filter the water in each body of water.

Currently we have no check valve on the POOL supply pipe, and everyday 0.5" water drains from the SPA into the POOL do to gravity while the automated valves transition from POOL to SPA and then later back to POOL again.

Of course, if I install a check valve on the POOL supply pipe I would have a definitive answer, but the piping is complicated and I would have to also replace 2-3port valves which I don't want to do unless also installing a check valve on the POOL supply pipe guarantees to solve the "problem" (ie SPA water level drops 0.5" per day).

My guess would be that with a check valve on the POOL supply line gravity would not allow water to naturally flow up and over the high-loop because there is nothing kick starting that flowing process? Unless the water, post high-loop, has enough suction (falling back into the pool) that it continues to draw water up and over the high-loop from the SPA until the valve transition completes.

See attached diagram with proposed new Check valve in black. Note, the check valves would/are of course be above ground (the brown line), but to keep the diagram simple, they are shown below ground.

Any thoughts?

Thanks!

When the automated valves (via daily schedule) are in between transitioning from POOL and SPA mode (they take about 20-30 seconds to completely transition), will the water flow from the SPA through the pump, over a high loop (higher than the top water level of the SPA), and back into the pool if there is a check valve on the POOL supply pipe? Note, there is no overflow/waterfall from SPA to POOL. They are treated like different bodies of water, and the Jandy Iqualink controller switches between POOL and SPA once a day to generated chlorine and filter the water in each body of water.

Currently we have no check valve on the POOL supply pipe, and everyday 0.5" water drains from the SPA into the POOL do to gravity while the automated valves transition from POOL to SPA and then later back to POOL again.

Of course, if I install a check valve on the POOL supply pipe I would have a definitive answer, but the piping is complicated and I would have to also replace 2-3port valves which I don't want to do unless also installing a check valve on the POOL supply pipe guarantees to solve the "problem" (ie SPA water level drops 0.5" per day).

My guess would be that with a check valve on the POOL supply line gravity would not allow water to naturally flow up and over the high-loop because there is nothing kick starting that flowing process? Unless the water, post high-loop, has enough suction (falling back into the pool) that it continues to draw water up and over the high-loop from the SPA until the valve transition completes.

See attached diagram with proposed new Check valve in black. Note, the check valves would/are of course be above ground (the brown line), but to keep the diagram simple, they are shown below ground.

Any thoughts?

Thanks!

Attachments

Last edited: