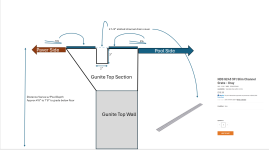

Ok, I have to keep reviewing the plans as the pool is quite unusual and I get lost on the details.

I think that the weir wall is 32 feet.

If you have a 32 foot long weir wall, then the amount of flow depends on the height you want to get over the weir.

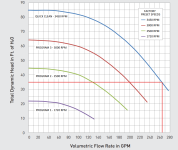

If we assume 5 GPM per linear foot of weir, that comes to 160 GPM.

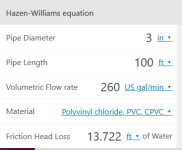

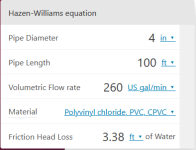

If we want 3/8" of lift, that comes to 264 GPM.

If you have (2) 3" lines for suction, then you can do up to 276 GPM.

I think that the weir wall is 32 feet.

If you have a 32 foot long weir wall, then the amount of flow depends on the height you want to get over the weir.

If we assume 5 GPM per linear foot of weir, that comes to 160 GPM.

If we want 3/8" of lift, that comes to 264 GPM.

If you have (2) 3" lines for suction, then you can do up to 276 GPM.

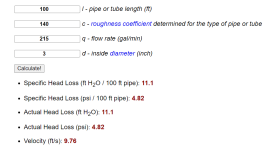

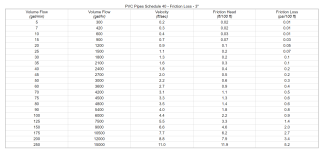

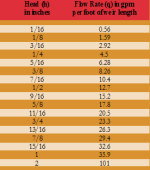

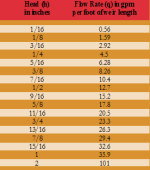

Pipe Size and Flow Rates.

You want to keep the water velocity below 6 ft/sec on the suction and below 8 ft/sec on the pressure side of the pump.[7]| Pipe Size | 6 ft/sec | 8 ft/sec |

|---|---|---|

| 1.5" | 38 GPM | 51 GPM |

| 2" | 63 GPM | 84 GPM |

| 2.5 | 90 GPM | 119 GPM |

| 3.0" | 138 GPM | 184 GPM |

| 4.0" | 235 GPM | 312 GPM |