The more you know. I thought it was to prevent leaks

You mean by filling tiny gaps between the threads? It does that, but not very well. If the joint moves after it's been tightened -- like if you back it off a little to realign it -- any tape that's been forced into the gap will loosen and the gap will unseal. Teflon tape's void filling property is way secondary to the lubrication.

Is the fear that the tape will allow you to apply so much force that you crack the fitting?

Yeah. The tightening spec for straight threads (like on most nuts and bolts) is a torque value, but for tapered pipe threads it's a number-of-turns value: For PVC, tapered-thread fittings must be tightened at least one turn, but no more than two turns, beyond finger tight.

If you mistakenly try to tighten to a particular torque value -- turning the fitting until it "feels" tight enough -- any lubrication in the joint will allow you to easily overtighten until the female side of the joint cracks. But even if you're aware of the number-of-turns rule, Teflon tape around the male threads will enlarge them, putting more bursting strain on the joint, and the female fitting may crack even with only two turns past finger tight.

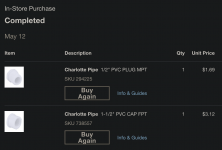

So the best way to assemble a tapered-thread PVC joint is to use a non-setting liquid thread sealant (make sure it's explicitly compatible with PVC) instead of Teflon tape. Put some on the threads, tighten to finger-tight (just to the point where the threads bind up, not hand-tight), then tighten one full turn, then tighten up to one more full turn if necessary to align the fitting.

This page seems to have a lot of good information:

lascofittings.com/threads

Very refreshing! Given how sweaty I was, I probably need to dial up the SWCG.

Very refreshing! Given how sweaty I was, I probably need to dial up the SWCG.