- May 4, 2018

- 65

- Pool Size

- 28000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

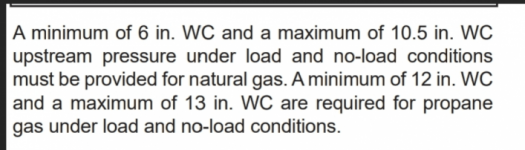

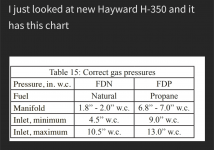

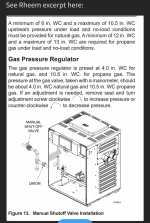

Hi. I'm trying to select a heater to replace an existing Hayward H-350 natural gas heater. I was leaning toward Raypak/Rheem based on all the great reviews here but when I started reviewing the installation manuals I noticed that the Rheem says it requires 6" W.C. upstream of the regulator with the regulator set to 4" W.C. Meanwhile the direct Hayward 350 replacement calls for 4.5" W.C. upstream with a manifold pressure of 1.8 to 2.0" W.C. Unfortunately I don't know what pressure the existing heater was getting when it was operational. It worked fine for a year after we bought the house and then died (was 20 years old)

Does it seem reasonable that the 2 designs would have such different pressure requirements or could this be a case of Raypak overstating their needs as a cya?

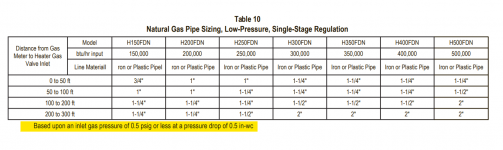

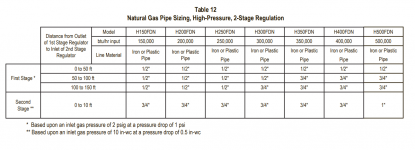

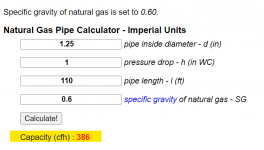

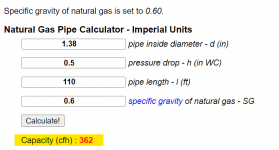

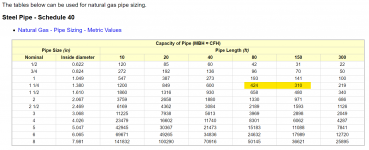

Assuming there is something inherent in the design of the Raypak that requires higher gas pressure, I'm leaning Hayward for peace of mind that it'll work. My best guess is that I have about 100 to 120 ft equivalent pipe length with 1 1/4" steel pipe which is tight to begin with. I have a comfort level that the old Hayward worked fine (it even actually apparently needed a little more at the manifold 3.5" vs the new Hayward which seems to need only 2.0).

I'm just looking for a sanity check on my thoughts above and any insight into the differences between the gas pressures required for the Hayward vs Raypak/Rheem natural gas heaters. As well as any other models I should be considering (Pentair? Jandy?). I am also trying to avoid overthinking it. It might be that if it worked for the old Hayward, it'll work for the Raypak and I end up with a heater that's not as reliable just because the manufacturer was less conservative in stating it's pressure requirements.

Any help would be greatly appreciated.

Ron

PS I attached a couple screenshots from the install manuals

Does it seem reasonable that the 2 designs would have such different pressure requirements or could this be a case of Raypak overstating their needs as a cya?

Assuming there is something inherent in the design of the Raypak that requires higher gas pressure, I'm leaning Hayward for peace of mind that it'll work. My best guess is that I have about 100 to 120 ft equivalent pipe length with 1 1/4" steel pipe which is tight to begin with. I have a comfort level that the old Hayward worked fine (it even actually apparently needed a little more at the manifold 3.5" vs the new Hayward which seems to need only 2.0).

I'm just looking for a sanity check on my thoughts above and any insight into the differences between the gas pressures required for the Hayward vs Raypak/Rheem natural gas heaters. As well as any other models I should be considering (Pentair? Jandy?). I am also trying to avoid overthinking it. It might be that if it worked for the old Hayward, it'll work for the Raypak and I end up with a heater that's not as reliable just because the manufacturer was less conservative in stating it's pressure requirements.

Any help would be greatly appreciated.

Ron

PS I attached a couple screenshots from the install manuals

Attachments

-

Screenshot_20230310-142129.png140.9 KB · Views: 66

Screenshot_20230310-142129.png140.9 KB · Views: 66 -

Screenshot_20230310-142228.png859.1 KB · Views: 11

Screenshot_20230310-142228.png859.1 KB · Views: 11 -

PXL_20230310_212852756.jpg725.3 KB · Views: 12

PXL_20230310_212852756.jpg725.3 KB · Views: 12 -

PXL_20230310_211217061.jpg643.3 KB · Views: 16

PXL_20230310_211217061.jpg643.3 KB · Views: 16 -

PXL_20230310_212716817.jpg437 KB · Views: 16

PXL_20230310_212716817.jpg437 KB · Views: 16 -

PXL_20230310_212757444.jpg622 KB · Views: 14

PXL_20230310_212757444.jpg622 KB · Views: 14 -

PXL_20230310_212842315.jpg560.9 KB · Views: 15

PXL_20230310_212842315.jpg560.9 KB · Views: 15 -

PXL_20230315_131547983.jpg314.6 KB · Views: 9

PXL_20230315_131547983.jpg314.6 KB · Views: 9 -

PXL_20230315_165759460.jpg423.8 KB · Views: 10

PXL_20230315_165759460.jpg423.8 KB · Views: 10

Last edited: