@Dirk, sorry for the delayed response. Pool was scheduled to be closed. That happened and I had to wait till this season. Now that I have a solution in place, it felt only right to share it with you, as you and the team here were so helpful in diagnosis.

I've replaced the intelliChlor Power Center board as well as the intelliPH board. I've thoroughly checked all components. The intelliChlor Cell is fine. The intelliPH motor appears to be fine. I did contact the OEM of that motor, who told me that if it was continuous around 7ohms it was fine. Mine checked at 6ohms, which he confirmed in email was fine. My acid check valve seems to work, but does not appear to be in good shape, so I replaced it..

I connected an ammeter inline with the pump. Running acid freely into a bucket pulled max 0.8A. Adding on the old and new check valves saw the same draw. New check valve running into the plumbing, same again. The motor draw oscillates as it turns from 0.5 to 0.8A. I doesn't sound like it used to, so I suspect something isn't quite right with that motor. I'm going to keep an eye on it.

Two errors I now know I could have made:

- My acid pump is tied in on the heater loop plumbing. When the pool heater is bypassed, the acid pump would be pushing against no flow. The check valve design isn't made for this, there has to be suction on the output and pressure on the input. At some point, I might have created this situation and overloaded the motor.

- I left the plastic pump tube run for over 2 years without replacement. When the motor started making weird noises, I replaced the tube, which made the motor sound better, but never again as it originally was.

I believe one of of the above errors caused the motor to draw too much current. There is no overload prevention in the motor. And there appears to be no overload prevention for the motor on the iPH board.

I believe

@generessler is right about the failure path. The pump pulled high amps on the 24v circuit. The intelliPH control board is powered at 48v but steps it down to 24v. There appears to be no over-current protection on the 24v side. Circuitry on the iPH board burned back from the motor. I believe that the comm bus and 48v power bus were shorted to one another when one of the chips burned. This went upstream to the comm bus circuitry on the intelliChlor board, burning out the comm chip only. Thus the intelliChlor continued to work, but no longer communicate with automation.

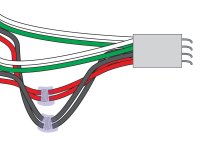

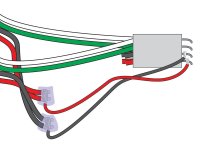

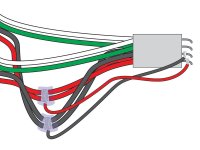

I also want to be cautious. The other threads you linked me to show very good reasons to believe that an intelliChlor can draw more than its rated current, and burn out the iPH board pins. I had pin burning. So I've added two inline fuses to the connecting wires:

- 1A inline fuse on the iPH motor.

- 7.5A inline fuse on the iChlor power connector.

Everything seems to work fine now. I'll report back to this group if I experience future issues. Pictures of the fuse arrangement attached.