@mas985

WOW thanks again for replying and having a look man!!!!

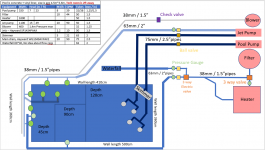

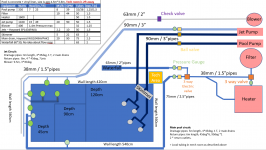

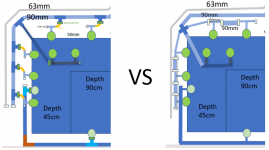

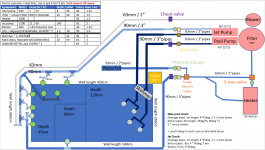

I have changed the scheme again into 2 separate loops as you said it should be.

I still want to use 2 pumps though.

I've added a new diagram with all the details (I hope)

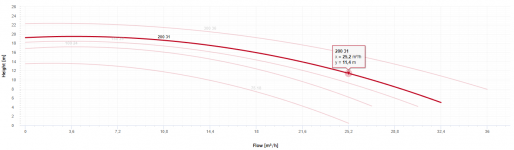

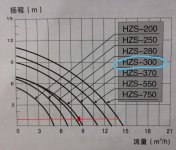

My jet pump:

Thing is - I have a 1 phase electricity system in my house and I'm very limited load-wise for the entire house, up to 40amps...

If there is any chance you can have a look and let me know if it might work that will be great!!!!

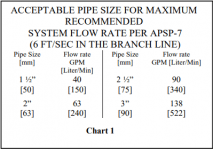

- Should I use 75mm tubing for the main drains? Can it be "BAD" if I use tubes that are "TOO BIG" or the bigger the better?

- Should I use bigger tube for the air blower as well?

WOW thanks again for replying and having a look man!!!!

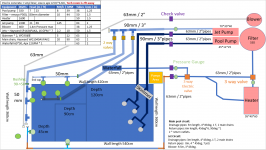

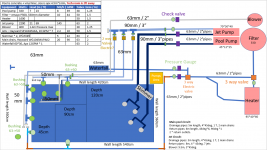

I have changed the scheme again into 2 separate loops as you said it should be.

I still want to use 2 pumps though.

I've added a new diagram with all the details (I hope)

My jet pump:

Thing is - I have a 1 phase electricity system in my house and I'm very limited load-wise for the entire house, up to 40amps...

If there is any chance you can have a look and let me know if it might work that will be great!!!!

- Should I use 75mm tubing for the main drains? Can it be "BAD" if I use tubes that are "TOO BIG" or the bigger the better?

- Should I use bigger tube for the air blower as well?