I was enticed by my local leslies pool company to install a pentair VS superflow for the energy savings. I'm doing everything but saving right now . Everything was working fine prior to install, after install Ive had nothing but trouble with my pool. I had leslies install the pool pump and since then Ive battled high filter pressure and low flow (12-15GPM vs when it's working is around 40-45GPM). I know because I have a flow gauge installed and I can tell by the speed of the water coming out of the water feature. My filter pressure is sitting at ~20lbs at 3000rpm w/15GPM on the gauge my baseline pressure is ~8lbs at 3000RPM when working correctly).

. Everything was working fine prior to install, after install Ive had nothing but trouble with my pool. I had leslies install the pool pump and since then Ive battled high filter pressure and low flow (12-15GPM vs when it's working is around 40-45GPM). I know because I have a flow gauge installed and I can tell by the speed of the water coming out of the water feature. My filter pressure is sitting at ~20lbs at 3000rpm w/15GPM on the gauge my baseline pressure is ~8lbs at 3000RPM when working correctly).

When the installer put the pump in initially it had a leak in the union joint on the pressure side (didn't catch till a few weeks after install) which seemed to be resulting in high pressure on the DE filter (~20-25lbs @3000rpm with a baseline of 8lbs at 3000RPM) and low flow. Before he came back I also cleaned/recharged the filter thinking maybe that might be causing the problem along with the leak so before he came back did my season cleaning of the Pentair FNS Plus filter. The LP guy wanted to clean inspect filter also to ensure I did everything correctly suspecting that might be causing the pressure issue in addition to leak so I let him also cleaned/inspect it which he said I did it correctly and the filter components / manifold were in good shape. Everything seemed to be fine and working correctly after he corrected the union joint problem but he didn't actually change out the union joint he just cleaned up the threading. My understanding was some of the glue from the joint above it dripped down on the threading and that's actually what caused the problem with the Union joint on the pressure side. He did not replumb it just use some type of glue cleaner and said "oh it's not leaking now so we don't have to replace it out". I was satisfied that it was fixed this because I noticed that the gallons per minute were way higher on my gauge (45GPM @ 3000RPM vs 15GPM @ 3000GPM when broken) then they had been since he's installed it but 3 days later my problem has resurfaced.

The only thing that I did from the time he left when it was working and the time it stopped working properly again is I cleaned/emptied the pump basket. When I remove the basket, because he braced the pump on this rock it's not very sturdy. I heard kinda like a scrape sound and the plumbing/pump somewhat moves when I take the basket off. Yes no leaks, but I suspect this should not happen if it is on a level surface and that shift could be causing a leak in the pressure side (but not seeing any water is that possible??) I really really hate the design of this new basket, it takes a decent amount of force to take it off versus my pentair challenger.

Things I checked:

-Skimmer baskets are clean and nothing is blocking them

-Skimmer doors are removed not gasping for air and clear of obstruction

-Not getting DE in the pool from jets, no air bubbles in jets

-I dont see any leaks on pressure or suction side

-Inspected the pump lid for debris on the o-ring and it's on flush with pool lube

-Inspected pump plugs to make sure they were tight and snug

-When pressure is high I try the pressure relief valve and no air is in in the tank

-Water levels are appropriate and not low

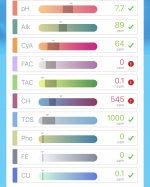

Anyways, this Monday I had my chlorine levels checked (prior to cleaning the pump basket) and they were perfect 2.87~ on FAC / Chlorine all other stuff in normal except my calcium is high (500ppm) which I think is related to my water in the area. Today is my normal pool cleaning day so I went ahead and check the water. I noticed the water feature was running too low again and sure enough I'm seeing the pump basket has water partially filled at the top. It seems to do this at low RPM? I run it at 1900RPM for about 10hours, 3000 for 6hours and 2400 for 8hours which worked fine for 3 days before I removed pump basket lid) and I'm back to where I started last week, low flow and high pressure. I've been managing this pool over a year so I'm pretty familiar with where I need to be chemical wise and unfortunately since this has been installed my chlorine usage has skyrocketed due to low flow. Any help would be great!

Pictures are here:

When the installer put the pump in initially it had a leak in the union joint on the pressure side (didn't catch till a few weeks after install) which seemed to be resulting in high pressure on the DE filter (~20-25lbs @3000rpm with a baseline of 8lbs at 3000RPM) and low flow. Before he came back I also cleaned/recharged the filter thinking maybe that might be causing the problem along with the leak so before he came back did my season cleaning of the Pentair FNS Plus filter. The LP guy wanted to clean inspect filter also to ensure I did everything correctly suspecting that might be causing the pressure issue in addition to leak so I let him also cleaned/inspect it which he said I did it correctly and the filter components / manifold were in good shape. Everything seemed to be fine and working correctly after he corrected the union joint problem but he didn't actually change out the union joint he just cleaned up the threading. My understanding was some of the glue from the joint above it dripped down on the threading and that's actually what caused the problem with the Union joint on the pressure side. He did not replumb it just use some type of glue cleaner and said "oh it's not leaking now so we don't have to replace it out". I was satisfied that it was fixed this because I noticed that the gallons per minute were way higher on my gauge (45GPM @ 3000RPM vs 15GPM @ 3000GPM when broken) then they had been since he's installed it but 3 days later my problem has resurfaced.

The only thing that I did from the time he left when it was working and the time it stopped working properly again is I cleaned/emptied the pump basket. When I remove the basket, because he braced the pump on this rock it's not very sturdy. I heard kinda like a scrape sound and the plumbing/pump somewhat moves when I take the basket off. Yes no leaks, but I suspect this should not happen if it is on a level surface and that shift could be causing a leak in the pressure side (but not seeing any water is that possible??) I really really hate the design of this new basket, it takes a decent amount of force to take it off versus my pentair challenger.

Things I checked:

-Skimmer baskets are clean and nothing is blocking them

-Skimmer doors are removed not gasping for air and clear of obstruction

-Not getting DE in the pool from jets, no air bubbles in jets

-I dont see any leaks on pressure or suction side

-Inspected the pump lid for debris on the o-ring and it's on flush with pool lube

-Inspected pump plugs to make sure they were tight and snug

-When pressure is high I try the pressure relief valve and no air is in in the tank

-Water levels are appropriate and not low

Anyways, this Monday I had my chlorine levels checked (prior to cleaning the pump basket) and they were perfect 2.87~ on FAC / Chlorine all other stuff in normal except my calcium is high (500ppm) which I think is related to my water in the area. Today is my normal pool cleaning day so I went ahead and check the water. I noticed the water feature was running too low again and sure enough I'm seeing the pump basket has water partially filled at the top. It seems to do this at low RPM? I run it at 1900RPM for about 10hours, 3000 for 6hours and 2400 for 8hours which worked fine for 3 days before I removed pump basket lid) and I'm back to where I started last week, low flow and high pressure. I've been managing this pool over a year so I'm pretty familiar with where I need to be chemical wise and unfortunately since this has been installed my chlorine usage has skyrocketed due to low flow. Any help would be great!

Pictures are here:

Last edited: