- Sep 15, 2021

- 117

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

To prevent water filling up the dig and prevent wall slideYou want to cover your pool dig during rain with a tarp or a trap?

Why?

To prevent water filling up the dig and prevent wall slideYou want to cover your pool dig during rain with a tarp or a trap?

Why?

Lol. Good catch on the typo!You want to cover your pool dig during rain with a tarp or a trap?

Why?

To prevent water filling up the dig and prevent wall slide

Hmm ok! So just leave it ?The water is still going to fill the hole over the tarp.

Hmm ok! So just leave it ?

Rebar going in tomorrow and rain forecast for next few days!Covering the walls with a tarp can prevent mud slides messing up the spacing between the walls and the rebar that will need to be repaired. The water will pool in the hole and you will need to wait until it dries or pump it out.

Rebar going in tomorrow and rain forecast for next few days!

Thanks for your reply. I’m build my own pool after getting much help guidance and help from this group. I’m planning to get a licensed geotechnical engineer to further evaluate this. Appreciate your further suggestions/feedback!S,

That's kind of difficult to answer. In general I would say there's nothing especially prohibitive about loose soil or any other kind of soil if the design acknowledges this and accounts for this. The main thing you should look for is a design that's stamped by a registered professional engineer in your state. If his design report says that the design requires a certain level of compaction for surrounding soil and/or soil below then you need to be sure the PB is demonstrating this is accomplished.

Chris

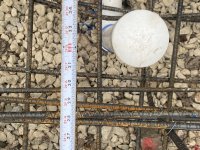

Yes. That’s right. The proximity to the rebar. Additional questions, I having 7*7 spa with 8 jets with separate jet pump. What should be the spacing between jets like 2’ etc and what should be height of these jets from the rebar ?#1: by raising the spa steel cage with Dobies your concern is with the height of the cage to the top of the wall forms, you need 3” from top of steel to top of form.

Cutting the rebar and repairing it is OK as long as the repair has a 24” overlap.

The main drain covers are set into rings and the rings are set into the plaster, the drain pipe will be cut lower than the ring to create a bowel and this is your concern because of its proximity to the rebar.