- Jun 10, 2009

- 336

- Pool Size

- 24000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

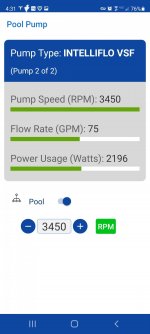

Here it is. Aqual cal recommended this as they said anything flow above 70gpm will damage the heater. I don't plan on going to 70gpm but with priming and also if someone else ever works on it or owns it, it's protected. What do you think?M,

Show me a close up of the heater by-pass set up you have...

Thanks,

Jim R.