- Jul 31, 2021

- 299

- Pool Size

- 11000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Ok after several years of delays and planning Im close (I hope) to ordering my heat pump (nat gas and propane not an option). I have decided to go with an Aquacal model SQ145 for the following reasons:

1) it looks to be very quiet as it is located about 8 feet from the pool deck

2) Has RS-485 that will talk with mt Pentair automation.

3) on the higher side for COP (4.2-7.1).

4) Has a very low PSI increase 2 PSI at 45 GPM other I have seen are 8-10 PSI this will translate to lower pump speeds

5) Available from a local dealer so hopefully support will be good if needed.

6) only needs 6" clearance in rear it needs to fit close to my house (I know more is better but space is tight)

Does anybody have this model or a similar one and what are your experiences?

I plan to do the install my self

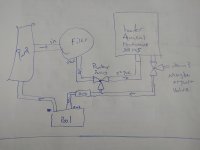

I have attached my plumbing diagram does this look ok am I missing something. I have a SWG so I don't think I need a check valve? Also I do want to be able to isolate the heater so included a couple 3 way valves. I also may automate one of the valves to bypass the heater is there any down side of only running water through heater in use? I assume it will put less stress on the heater. I am toying with using one of the 3 way valve to provide a method to drain the pool using the pump. I also don't think I need any sort of flow bypass when my pump is at max speed( I never run it there) the flow tops out 76 GPM the max rated on the heat pump is 70 I assume the added flow restriction of HP and new plumbing will bring it down below 70 and don't ever plan of running the pump at max speed anyway.

The cardboard on the ground is the approximate size of the heater.

1) it looks to be very quiet as it is located about 8 feet from the pool deck

2) Has RS-485 that will talk with mt Pentair automation.

3) on the higher side for COP (4.2-7.1).

4) Has a very low PSI increase 2 PSI at 45 GPM other I have seen are 8-10 PSI this will translate to lower pump speeds

5) Available from a local dealer so hopefully support will be good if needed.

6) only needs 6" clearance in rear it needs to fit close to my house (I know more is better but space is tight)

Does anybody have this model or a similar one and what are your experiences?

I plan to do the install my self

I have attached my plumbing diagram does this look ok am I missing something. I have a SWG so I don't think I need a check valve? Also I do want to be able to isolate the heater so included a couple 3 way valves. I also may automate one of the valves to bypass the heater is there any down side of only running water through heater in use? I assume it will put less stress on the heater. I am toying with using one of the 3 way valve to provide a method to drain the pool using the pump. I also don't think I need any sort of flow bypass when my pump is at max speed( I never run it there) the flow tops out 76 GPM the max rated on the heat pump is 70 I assume the added flow restriction of HP and new plumbing will bring it down below 70 and don't ever plan of running the pump at max speed anyway.

The cardboard on the ground is the approximate size of the heater.

Attachments

Last edited: