James, you asked me to post temp differences at various speeds. I will do that today or tomorrow. Unless you tell me otherwise I will do it this way... select maybe three RPMs, at each one I'll note the reading on the heater for the temp coming in to the heater, then run water directly out of the return into a bucket and read the temp.

Coordinating VSP Filter Pump with Heat Pump Heater

- Thread starter burgerchef

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

It just requires a little experience. I wrote the spreadsheets mostly for myself but I make them available to others so documentation is somewhat limited.Mark, stumbling through my edit attempt on your doc, I see very little difference regarding what I thought was a big one.

I was just trying to factor in my estimation of pipe lengths and fittings, I did not understand how that was notated.

Thanks for the "live" lesson!

Your calculations for Prepanel Total Dynamic Head Loss (ft) - 18.06

Your calculations for Postpanel Total Dynamic Head Loss (ft) - 33.3

With my edit calculations for Prepanel Total Dynamic Head Loss (ft) - 23.11

With my edit calculations for Postpanel Total Dynamic Head Loss (ft) - 30.4

Total difference is only 2.05, but I don't know if that means anything.

I think you may still have the wrong lengths and counts in the spreadsheet. You need to use the equivalence formula that I posted earlier. I put in a column to the left of yours to illustrate how this is used. If you give me the individual counts, I can update the values.

But with the parallel runs, the values are diminished because they are parallel so even large changes don't have a large effect.

Focus only on lines before 160. Lines after 159 are for spa jets and Lines after 168 are for Solar.Worse yet, I now know that at one point I'm looking at the term "Total Dynamic Head In Feet", then later see "Total Dynamic Head Loss" and equate the two. I'm now assuming they are not the same. I have learned a few things from you and James and will absorb more as I continue to review it all. However I am far too ignorant in this to grasp the majority of it.

I probably need to label those better.

Please see attachment showing graphs. Do I have this right? I think the smallest one shows an early identified system curve C as being close to my situation and that is a fairly good situation. Then did the top big chart show that a different approach to calculation had a curve result that is very close to C from the previous graph. Then does the bottom chart add a curve that my (OP?) try would produce? Does it show something impossible? All other curves start at 0/0. It shows 42' head with 0 GPM.

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Not exactly.Please see attachment showing graphs. Do I have this right?

That graph is just showing the standard plumbing curve B, A, C & D. It is not showing any calculation or estimates. Those plumbing curves are just references your plumbing curve just happens to be is very close to Curve C. Also those plumbing curves are exactly the same ones also show in the larger charts.I think the smallest one shows an early identified system curve C as being close to my situation and that is a fairly good situation.

The difference between the two is that the top is the full dynamic plumbing curve which is valid for all RPM values.Then did the top big chart show that a different approach to calculation had a curve result that is very close to C from the previous graph. Then does the bottom chart add a curve that my (OP?) try would produce? Does it show something impossible? All other curves start at 0/0. It shows 42' head with 0 GPM.

The bottom chart OP plumbing curve is a graphical solution to the filter PSI operating point calculation and was only meant to show the method of how the pump operating point is determined from the filter PSI. The point of this chart was to show that the filter PSI is basically a fixed head loss at a fixed RPM and the unknown contribution was from the other plumbing not included in the filter PSI (e.g. pre-gauge plumbing). To find the solution to the equation, one needs to find the intersection of that plumbing curve on top of the pump curve. So this curve can only be used at one RPM, 3450, and only to determine the pump's operating point (GPM, Head). After which the full dynamic plumbing curve can be calculated and used (top chart). So this was only for instruction and not meant to be used in general.

So in summary, the top can be used for any RPM but the bottom is only value for 3450 RPM.

Near skimmer - 30'. H = 0.002F12.

Bottom Drain - 40' (depth factored in). H = 0.0027F22.

Far skimmer - 88'. H = 0.006F32.

A = Near skimmer line coefficient.

B= Bottom Drain line coefficient.

C = Far skimmer line coefficient.

D = Combined Coefficient.

D = A/(sqrt(A/B) + sqrt(A/C) + 1)^2

A = 0.002, B = 0.0027, C= 0.006.

D = 0.0003365

Bottom Drain - 40' (depth factored in). H = 0.0027F22.

Far skimmer - 88'. H = 0.006F32.

A = Near skimmer line coefficient.

B= Bottom Drain line coefficient.

C = Far skimmer line coefficient.

D = Combined Coefficient.

D = A/(sqrt(A/B) + sqrt(A/C) + 1)^2

A = 0.002, B = 0.0027, C= 0.006.

D = 0.0003365

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

It doesn't look like you included the fittings or the smaller diameter for the flex.

0.002A^2 = 0.0027B^2 = 0.006C^2, A + B + C = 100

A = 41.017%

B = 35.3018%.

C = 23.6812%

www.wolframalpha.com

www.wolframalpha.com

Percent flow 1 = 1/(1 + sqrt(A/B) + sqrt(A/C)), A = 0.002, B = 0.0027, C= 0.006.

1/(sqrt(A/B) + sqrt(A/C) + 1) = 0.41017

www.wolframalpha.com

www.wolframalpha.com

For a total of 60 GPM, the flow in line 1 = 24.61 GPM.

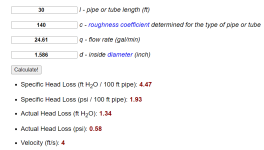

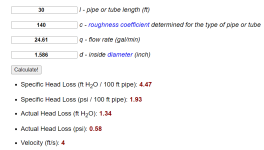

1.34/60^2 = 0.0003722

www.engineeringtoolbox.com

www.engineeringtoolbox.com

A = 41.017%

B = 35.3018%.

C = 23.6812%

0.002A^2 = 0.0027B^2 = 0.006C^2, A + B + C = 100 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

Percent flow 1 = 1/(1 + sqrt(A/B) + sqrt(A/C)), A = 0.002, B = 0.0027, C= 0.006.

1/(sqrt(A/B) + sqrt(A/C) + 1) = 0.41017

1/(1 + sqrt(A/B) + sqrt(A/C)), A = 0.002, B = 0.0027, C= 0.006. - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

For a total of 60 GPM, the flow in line 1 = 24.61 GPM.

1.34/60^2 = 0.0003722

Hazen-Williams Water Flow Formula: Head Loss, Data, Charts & Calculator

Friction head loss (<i>ft<sub>H2O</sub> per 100 ft pipe</i>) in water pipes can be estimated with the empirical Hazen-Williams equation.

Attachments

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I always go with a smaller diameter than the specs because flex has ripples in the surface which makes the hydraulic diameter slightly smaller than the physical diameter.

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Also, I found that flex comes in many different sizes for a 1.5" label.

This is 1.5" nominal with very high ridges which means it has an even smaller hydraulic diameter than 1.5":

spadepot.com

spadepot.com

There seems to be a large variety of sources so it isn't 100% clear what is actually in the ground so I like to be somewhat conservative which is why I chose 1.5" HD.

Also, if you want to compare to what I estimated, all of the individual components, including the fittings, are listed in the spreadsheet:

docs.google.com

docs.google.com

I still have not reconciled everything with the OP regarding the fittings for each line.

Also, other plumbing not included in filter PSI is not only the parallel suction lines but the combined section right before the pump and the pump to filter section.

This is 1.5" nominal with very high ridges which means it has an even smaller hydraulic diameter than 1.5":

PVC Flex Pipe 1.5" - 10 ft. Roll

Premium Spa Flex Hose - 1.5" x 10' Roll. This ribbed PVC flex tubing is Schedule 40, and works with regular PVC cements & cleaners. Ideal for hot tub plumbing!

There seems to be a large variety of sources so it isn't 100% clear what is actually in the ground so I like to be somewhat conservative which is why I chose 1.5" HD.

Also, if you want to compare to what I estimated, all of the individual components, including the fittings, are listed in the spreadsheet:

Pool Pump Tools v030 - burgerchef

I still have not reconciled everything with the OP regarding the fittings for each line.

Also, other plumbing not included in filter PSI is not only the parallel suction lines but the combined section right before the pump and the pump to filter section.

The ridges will also create more friction and turbulence compared to smooth PVC, so that will introduce more resistance.

Getting a vacuum pressure would be helpful.

Maybe a flow meter would be useful if you want to be more sure.

www.h2flow.net

www.h2flow.net

Maybe a flow meter would be useful if you want to be more sure.

FlowVis flow meter — H2Flow Controls

FlowVis flow meters are a revolution in reliable flow measurement. With unrivaled average accuracy, greater installation flexibility, and more NSF 50 certified models than any other brand, it’s easy to see why FlowVis® is a brand of flow meter you can put your trust in.

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Correct but that additional friction loss can be modeled as a smaller HD which is what I am doing the SS model and why I chose a smaller HD than the typical flex ID.The ridges will also create more friction and turbulence compared to smooth PVC, so that will introduce more resistance.

Models such as OpenFoam use a variant of this technique (i.e. wall functions) to model rough surfaces.

In any case, it demonstrates the power of parallel lines to reduce head loss.

The head loss drops by a factor of roughly the number of lines squared assuming equal lines.

1 line = 1.

2 lines = 1/4th.

3 lines = 1/9th head loss etc.

A/(sqrt(A/B) + sqrt(A/C) + 1)^2 = 0.000444444

www.wolframalpha.com

www.wolframalpha.com

The head loss drops by a factor of roughly the number of lines squared assuming equal lines.

1 line = 1.

2 lines = 1/4th.

3 lines = 1/9th head loss etc.

A/(sqrt(A/B) + sqrt(A/C) + 1)^2 = 0.000444444

A/(sqrt(A/B) + sqrt(A/C) + 1)^2, A = 0.004, B = 0.004, C= 0.004. - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

In reality, that section of the plumbing as well as the return doesn't matter much to the operating point so even it is wrong, the results are still right.

If you have 1,000 suction lines and 1,000 return lines, you can reduce the head loss by a factor of 1,000,000, which is nice.The head loss drops by a factor of roughly the number of lines squared assuming equal lines.

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Or you could just increase the diameter of pipe by a factor of ~14x which might be a little more cost effective.

Not sure if you are waiting for my estimate on this from me.I still have not reconciled everything with the OP regarding the fittings for each line.

At one point during construction I saw the underground plumbing in place but don't remember if there were many 45 or 90 fittings. Would you agree that probably most "turns" are accomplished by the flex pipe sweeping?

Underground Suction

Flex pipe sweeps - 11

90s - guess 3

45s - guess 3

Unions - guess 3

Underground Pressure

Flex pipe sweeps - 8

90s - guess 2

45s - guess 2

Unions - guess 2

Everything above ground is visible in the photo I posted showing the filter pad, there are no fittings at the heater pad.

Attachments

- May 3, 2007

- 18,097

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I was more interested in what each individual line had and not the totals. It won't matter that much either way.

But on the suction, each line should have at least 2 90s. One is shown at the pad in the picture and I would assume there is one on each skimmer and probably the main drain.

But on the suction, each line should have at least 2 90s. One is shown at the pad in the picture and I would assume there is one on each skimmer and probably the main drain.

Here are four differentials at different speeds. I compared the heater readout to my thermometer. Weeks ago I did the test on two different days but did not note the RPM. One was two and the other was three.Can you check the temperature differential at different speeds?

2400 RPM - 82 to 85 - 3

2800 RPM - 78 to 80 - 2

3000 RPM - 80 to 81.5 - 1.5

3400 RPM - 79 to 80- 1

3 degrees is about 80 GPM.2400 RPM - 82 to 85 - 3

2800 RPM - 78 to 80 - 2

3000 RPM - 80 to 81.5 - 1.5

3400 RPM - 79 to 80- 1

However, this method is not super accurate as 1 degree can make a big difference and we do not know the exact heater output.

I do not think that you are getting 80 GPM at 2,400 RPM with that pump.

In any case, I would use 2,000 RPM.

If you want better accuracy, you can get a flowmeter and see what that shows.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.