Hello,

I move to a house where a pool heater was installed for the SPA, including gas pipe line, except that the gas meter it was not connected. At that moment, the owner mentioned he never used the heater and I suspected the gas line got leaked somehow and didn't pass the annual check.

A few months ago, I performed a test pressure from end to end (30 psi for 12 hours) and got positive results.

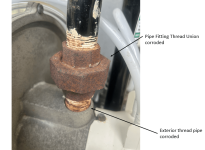

At this time, I'm performing an inspection of the heater and found many screws and nuts for the plastic case are rusted, the Automatic Gas Shutoff (AGS) terminals broke while extracting the cable connector and the High limit switch (HLS) terminal seems rusted as well. Besides these parts everything else seems acceptable.

Based on your experience, there is another part I need to take care of before performing any test?

It would be possible to use the PEX gas pipe of 3/4 (20mm) with length of ~68.5 meters from the meter area to the heater? Attached some pictures for reference.

Thanks in advance

I move to a house where a pool heater was installed for the SPA, including gas pipe line, except that the gas meter it was not connected. At that moment, the owner mentioned he never used the heater and I suspected the gas line got leaked somehow and didn't pass the annual check.

A few months ago, I performed a test pressure from end to end (30 psi for 12 hours) and got positive results.

At this time, I'm performing an inspection of the heater and found many screws and nuts for the plastic case are rusted, the Automatic Gas Shutoff (AGS) terminals broke while extracting the cable connector and the High limit switch (HLS) terminal seems rusted as well. Besides these parts everything else seems acceptable.

Based on your experience, there is another part I need to take care of before performing any test?

It would be possible to use the PEX gas pipe of 3/4 (20mm) with length of ~68.5 meters from the meter area to the heater? Attached some pictures for reference.

Thanks in advance