I have a Pentair MasterTemp 400K BTU Heater that is under warranty (pool startup was Thanksgiving 2021...so ~21 months ago). It recently started leaking, and the technician came out yesterday and confirmed that it is totaled. He pulled off the heater manifold, and the copper tubing had corroded through. He also tested the water, which showed high in copper and an alkalinity level of 50 (I tested when he left and my TFP kit shows between 60 and 70). In general. I have always targeted TA between 60 and 80 (per the TFP app) and a pH of 7.6. The alkalinity level is usually on the money (70ish), and pH (if anything) gets a little high...but it's mostly stable, so I rarely have to add muriatic acid.

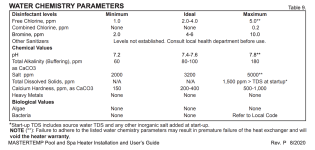

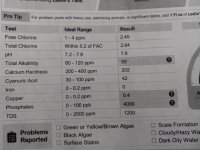

I have not heard anything official from Pentair yet, but the tech says that they will likely deny the claim. He says that the ideal alkalinity is 80-100, and low alkalinity would be the reason that my heater failed. Prior to the discussion with the tech, my understanding was that low pH (not low alkalinity) would eat through metal components. Either way though, my pool chemistry has always stayed pretty close to the TFP recommendations. Per page 60 of the Pentair manual, the ideal pH is 7.4 to 7.6. I have definitely stayed in that range or higher. The ideal alkalinity range shows 80-100, but it shows a minimum of 60.

So, I guess my questions are:

I have not heard anything official from Pentair yet, but the tech says that they will likely deny the claim. He says that the ideal alkalinity is 80-100, and low alkalinity would be the reason that my heater failed. Prior to the discussion with the tech, my understanding was that low pH (not low alkalinity) would eat through metal components. Either way though, my pool chemistry has always stayed pretty close to the TFP recommendations. Per page 60 of the Pentair manual, the ideal pH is 7.4 to 7.6. I have definitely stayed in that range or higher. The ideal alkalinity range shows 80-100, but it shows a minimum of 60.

So, I guess my questions are:

- Anyone had experience with Pentair in this regard? I guess it's my word against theirs on the chemistry...can I fight this with logs?

- What TA should I really be targeting? 80-100?

- Can low TA really cause copper to deteriorate and fail? No, right? Should be low pH. Either way, I really wish I had followed the Pentair recommendations rather than TFP...at least until my warranty had expired.

- Why would there be a discrepancy between the tech's TA test and my TFP TA test?

- Copper in the water seems bad...do I need to drain/refill?