The operation of the check valve is dependent on the flow which could be effected by dirty filter and pump speed

That's how it is designed to work.

It only opens when the flow is over about 58 GPM with a 5 lb check valve.

GPM...........Pressure differential

30...................0.2167 psi

40...................2.0 psi

48...................3.5 psi

50...................3.7 psi

58...................5.0 psi

60...................5.2 psi

70...................6.3 psi

80...................6.8 psi.

The check valve operation could be affected by chemical breakdown

Everything eventually breaks down.

What serviceability service will be performed on the valve during its lifespan

I would put unions on both ends of the check valve and have a replacement with the same unions just in case the original ever fails.

For all Jandy check valves, I would get one spare for each size so that you can have a replacement ready to go if one fails, which will probably happen.

When it fails how will it tell you

It's clear and you can see it working.

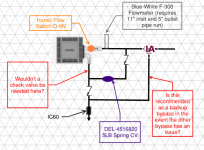

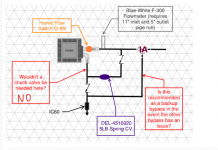

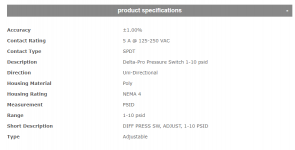

The heater already has a pressure switch in it so unless the spa/pool is more than 4” above or below or on a commercial installation a external flow switch isn’t needed

Completely wrong.

The pressure switch can be activated with no flow when the bypass is being used because pressure can be trapped in the heater.

Using a simple pressure switch on the heater inlet is foolish because it does absolutely nothing to ensure that there is any actual flow.

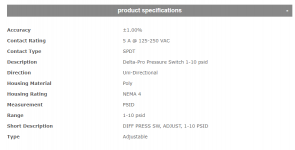

The only way that a pressure switch would be reliable would be if it was a

differential pressure switch that measured the difference in pressure between the inlet and the outlet.

Dwyer Instruments

www.dwyer-inst.com

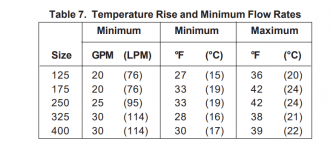

Unless larger than 2” pipe is used on the system the max flow through the system at 7FPS is rated at 72GPM using sch 40 PVC pipe.

I don't understand what this is asking.

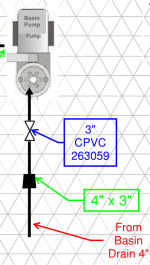

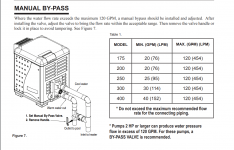

The plumbing to the heater is 2" and the bypass is 2", so the flow will begin diverting around the heater at about 58 to 60 gpm.

So, you will have 60 gpm going to the heater and 60 gpm going through the bypass at 120 gpm total.

Even if you didn't have a bypass, you can send 120 gpm through a 2" line and through the heater.

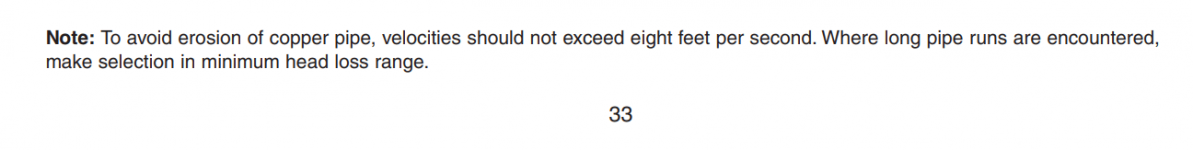

For suction, you want to keep the water velocity below 6 ft/sec. For returns, you want to keep the water velocity below 8 ft/sec.

Size.......6 ft/sec......8 ft/sec.

1.5"...........38...............51 gpm

2"..............63...............84 gpm

2.5............90.............119 gpm

3.0".........138............184 gpm

4.0"........238.............317 gpm

Without a bypass, you could use 2.5" plumbing to the heater which is 8 feet per second.

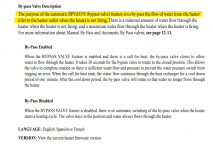

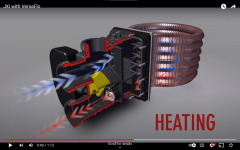

Inside the heater, there is a spring bypass and all of the water goes through the bypass when the heater is not heating.

A thermal regulator blocks the flow from exiting the heat exchanger until the water warms up.

The internal manifold bypass is about 2" in diameter.

Below, you can see the manifold bypass and the thermal regulator.

When the heater is on, part of the flow goes through the manifold bypass and part of the flow goes through the heat exchanger.

Putting 120 GPM through the manifold bypass is about 12.3 feet per second and it puts a lot of stress on the plunger and it can break off as shown in the below video.

Below is a picture of an old and a new heat exchanger.

The old one developed a leak and had to be replaced.

The heat exchanger can develop a leak due to corrosion caused by chemical damage or by excessive flow causing mechanical erosion.