- Jun 9, 2021

- 79

- Pool Size

- 17500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Ok. Then I think I have my answer b/c I’m not going to mess with pvc joints. Digging time!Those are only meant for polyethylene tubing.

Any ideas where to look for 2” risers in stock? HD would not give me an eta. Will take me a while to get this trench dug anyway.

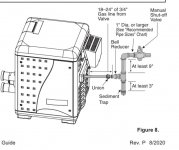

I assume that I can buy fittings to reduce from 2” to 0.75” at heater (after riser).