- Jun 9, 2021

- 79

- Pool Size

- 17500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Ok guys,

maybe ill cut off the elbow just to see if there is steel in the tube and the pvc is just a rust sleeve?

But seems like the consensus is a lousy job and patch work all around...

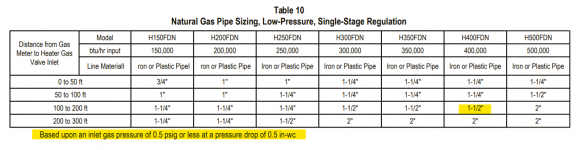

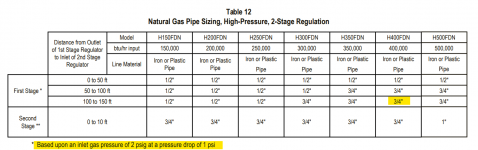

If Im already invested this far, why not go all the way, and can opt for 2" to be safe, since its 125 feet min before factoring in a bunch of elbow fittings/couplers...

maybe ill cut off the elbow just to see if there is steel in the tube and the pvc is just a rust sleeve?

But seems like the consensus is a lousy job and patch work all around...

If Im already invested this far, why not go all the way, and can opt for 2" to be safe, since its 125 feet min before factoring in a bunch of elbow fittings/couplers...