- May 7, 2021

- 61

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

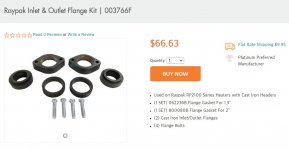

So I hace a Raypak 337a, Cast Iron Header with flange gaskets. I'm running into a problem which is, when I tighten the flange bolts, to match the installation instructions picture, the gasket deforms and pops inside out of the seat. Doesn't say anything in the manual about how tight to make this or how loss. Any suggestions on this? Attached is the page from manual, circled the gasket I'm using and arrow showing the gap Raypak is depicting. I guess the questions are, should the flange be touching the header? If not, how tight is tight enough, I know, it's like asking how long is a piece of string?

What everything looks like before hand:

Before tightening:

After tightening:

What everything looks like before hand:

Before tightening:

After tightening: