So I mentioned NB refunded me $110 off my $320 kegging kit I bought (the price of a dual output CO2PO regulator), after the second regulator had the same issues the first one did. I think it's just a cheap design, not a manufacturing flaw, as all 4 regulators (both regs on both sets of dual regs) would not flow until the pressure dropped ~5 psi from the setpoint. This included the one I took apart. Regulator is connected to an empty keg to simulate real life operation by giving it volume to refill.

Compare that to the used Airgas regulator I bought off of eBay. It has a sticky low pressure gauge, which is why I'm tapping the gauge, but the regulator is pretty solid. I do note that it tends to recover to about 1/2 psi higher than the initial setpoint, but after that first flow it stays there. In other words, if I set it to 7 on an empty keg it seems to fill to 7, then after I flow some gas might go to 7.5 psi, but subsequent flows recover to 7.5 psi.

And more importantly, it starts flowing gas almost immediately upon a pressure drop. I should have gone with a used industrial regulator from the start and saved myself a lot of hassle (or new, but industrial grade regulators like this run about $300 new).

ADDENDUM: Thought I posted this yesterday, guess I didn't. Now I'm not so sure about the used Airgas regulator. I left it connected to my cider keg overnight. Woke up at 2 am with a loud hissing. The regulator decided to stick open and the keg pressure relief was venting. So perhaps the regulator was not the deal I thought it was.

You are going to want to have some room in the keezer for bottles and other stuff also so you can use the hump for that. Or you can do what I do. Go and buy a used Coca-Cola keg or two (they don't make these new) and one or two post conversion kits to ball. They are wider/fatter but also shorter.

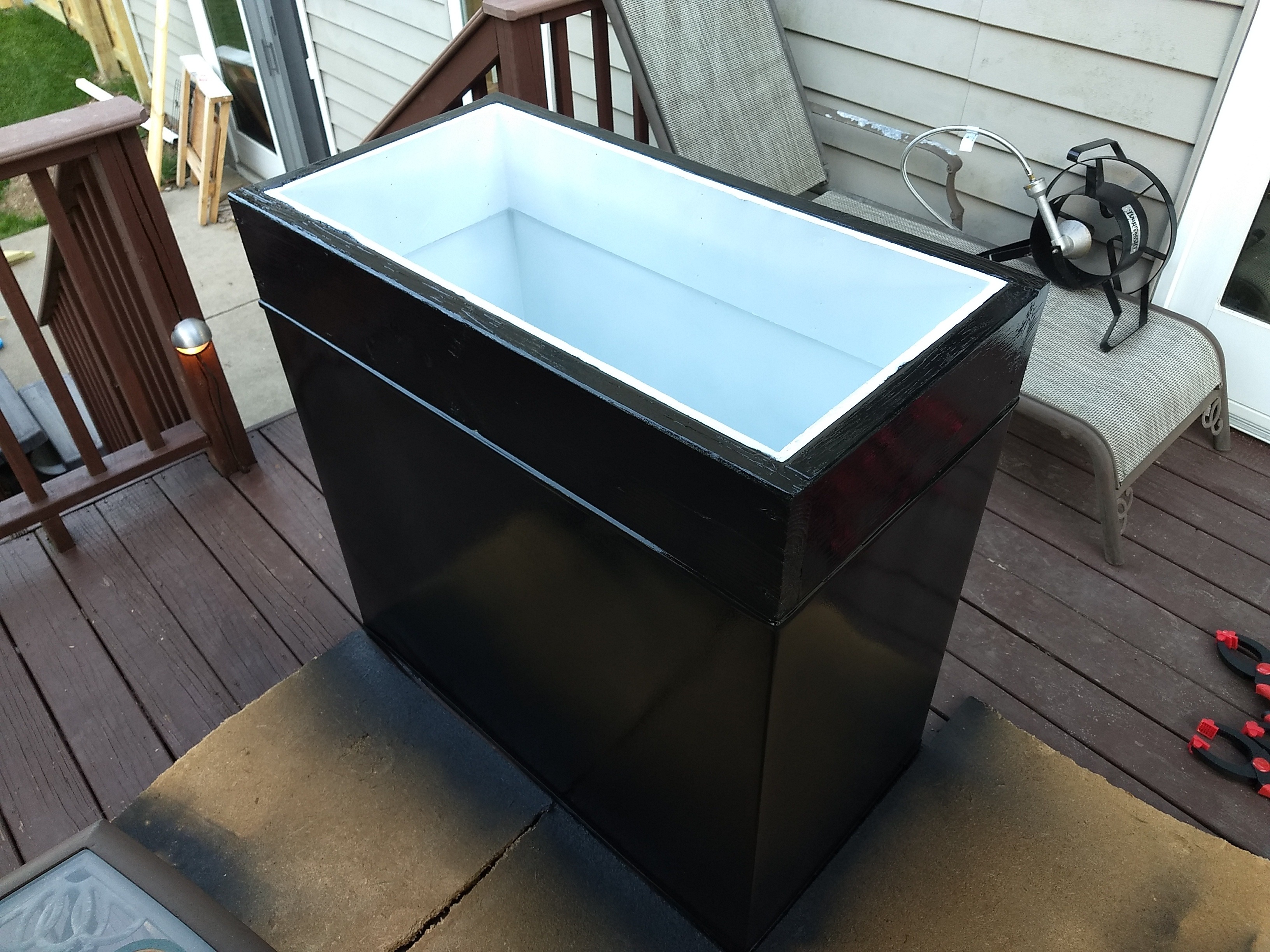

Yeah. So I only needed a 2x4 if I didn't need kegs on the hump. With a 2x6 it was just a tad short to put an unconnected keg. 2x8 fits an unconnected keg, and a 2x10 would have fit a connected keg. But it's a tradeoff with height (so accessibility and lifting full kegs) vs usefulness.

I decided I did not need more than 5 connected kegs, and probably wanted room for bottles and such, like you mentioned. But I did decide to use a 2x8 so I could fit an unconnected keg. If one of the kegs on tap is getting low, and I want to replace it as soon as it is gone, I can force carb a room temp keg of the same type (assuming I have stuff in the pipeline) by rolling or shaking it for a while, then disconnect and put on the hump to cool down and be ready to go by the time the keg on tap kicks it.

As I mentioned the 2x8 also leaves room for a carboy to cold crash on the hump, if desired.