- Jul 2, 2014

- 752

- Pool Size

- 19000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I'm looking for a good way to hang my leaf net, brush, vacuum, etc.. pole attachments. Surprisingly I have not found any 3D printer designs I like. Before I attempt to design one myself, I wanted to see if any of you have anything.

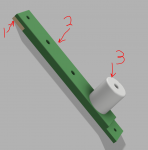

I just want a single bracket with screw holes top and bottom. In the center a plastic cup/post that either the attachment can slide into or slip over. Similar to the image below.

I just want a single bracket with screw holes top and bottom. In the center a plastic cup/post that either the attachment can slide into or slip over. Similar to the image below.