My coworker just replaced his single speed 1HP Superflo with a Superflow VS. Power went from 1.4KW to <200W (at 1400RPM). Tons of flow on the skimmer still. That's fantastical!

Pretty sold on the VS upgrade. Three options

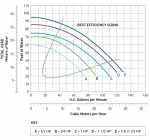

I know the Intelliflo is higher HP, but is it really worth almost double? My pool may have higher head than my coworkers (equipment is higher and further away). So I may need to run the SuperFlo VS at a higher RPM than the Intelliflo? The Intelliflo may be more efficient, but if the SuperFlo VS is really like 200W, it would be hard to justify the $500 difference.

What about the difference in the SuperFlo VS pump head vs the Pentair Challenger pump head? Worth the $250?

Pretty sold on the VS upgrade. Three options

- Upgrade the motor on the pump I have now (1 HP single speed high pressure). Gets me the VS for about $427, re-use the existing pump head

- Change the unit for the SuperFlo VS. ~$700.

- Change the unit for the Intelliflo VS. ~$1200.

I know the Intelliflo is higher HP, but is it really worth almost double? My pool may have higher head than my coworkers (equipment is higher and further away). So I may need to run the SuperFlo VS at a higher RPM than the Intelliflo? The Intelliflo may be more efficient, but if the SuperFlo VS is really like 200W, it would be hard to justify the $500 difference.

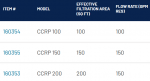

What about the difference in the SuperFlo VS pump head vs the Pentair Challenger pump head? Worth the $250?