How Should Multiple SWG Cells be Setup in a Pool?

Why are Multiple SWG Cells Needed in a Pool?

Sometimes a pool needs the generating capacity of more than one Salt Water chlorine Generator(SWG). This may be because the pool volume is greater than the capacity of a single cell; too small a cell was installed and additional capacity is needed; or you want the redundancy of multiple cells in case one cell fails.

Depending on the manufacture the largest cell in their product line may be for a 40,000, or 60,000 gallon pool. Note that manufactures specification assume the cell is run 24/7 at 100% of capacity. At TFP we recommend you oversize your cell by at least 2X your pool volume. A 40K cell is best for pools 20,000 gallons of below.

Oversizing the SWG capacity creates challenges for large pools of around 40,000 gallons and above. In those situations installing multiple cells may be the solution.

Connecting Multiple SWG Cells Serial or Parallel? Horizontal or Vertical?

In general multiple cells should be connected in parallel for best performance. Although with two SWG cells in a residential pool a parallel or serial water flow will likely work fine.

Parallel Water Flow

With parallel water flow each cell gets the same salt concentration in the water for maximum cell generation performance.

Adequate water flow is required to provide flow through each cell and close each cells flow switch.

Serial Water Flow

With a serial flow of water through cells there is a concern of lessening of salt concentration in water on the downstream cells. Although the conversion from chloride to chlorine only removes a few ppm of the salt. So, the effect is negligible.[1]

The bigger issue is that the gasses created keep the blades from being completely wetted and that would be the primary reason for diminished capacity.

Series should probably be limited to 2 or 3 in series.

Cells positioned Horizontal or Vertical?

SWG cells generate chlorine and hydrogen gas bubbles. With multiple cells gas bubbles need to be handled by configuring the cell’s orientation properly.[2]

The Pentair Comsys described below positions the cells vertically, likely for gas bubble management.

The cells need to have adequate flow rates for gas entrapment to be manageable.

Controlling Two SWGs in a Pool

Usually you are using two SWGs because one does not give adequate chlorine generation. Set one SWG to 100% then vary the % output of the other SWG to meet the pools Free Chlorine needs.

A pool automation system can only control one SWG.

Large Capacity Commercial SWG Systems

Manufactures sell systems to control multiple SWGs in large pools, typically for commercial use.

Note that SWG cells gallon size for commercial pools are less then similar residential pool cells to account for the chlorine demand of high bather loads in commercial pools.

Further discussion about commercial SWG systems can be found at Salt Chlorine Pools Are Becoming The Norm For Commercial Pools and Spas.

Pentair Commercial IntelliChlor Commercial Systems (COMSYS)

The Pentair commercial systems come in cell configurations from 2 to 8 cells producing 4lbs of chlorine per day to 16lbs of chlorine per day.

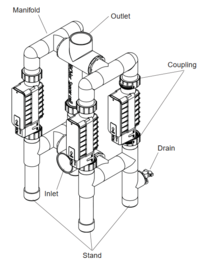

The commercial systems use a 4 port manifold to parallel cells. A straight pipe installed in the manifold for odd numbers of cells.

IntelliChlor COMSYS-6 System 520972

The IntelliChlor COMSYS-6 System 520972 consists of three IntelliChlor (SCG) cells and three powercenters (one primary and three secondary). Each cell can produce up to 2.00 lbs of pure chlorine per 24 hours of operation. These cells can sanitize either a pool or spa, or combination of both.[3]

The COMSYS-6 uses IC60 like cells for a total output of 6-lbs of chlorine per day. One cell is the PRIMARY and the others are the SECONDARY. The PRIMARY reads the salt level and communicates to the SECONDARY cells through the Power Center communication connections.

The cells are positioned vertically and connected with parallel water flow through Pentair supplied manifolds.

IntelliChlor COMSYS-16 System 520977

The IntelliChlor COMSYS-16 uses seven additional secondary cells and manifolds to support a 150,000 gallon pool. This setup runs water through the manifold in four parallel paths with two cells in series in each water path.

Intellichlor Comsys Cells

The cells used in the COMSYS are different than the residential IC60 cells in that they are setup to be a PRIMARY or SECONDARY cell and have commercial coated cell blades. The PRIMARY reads the salt level and communicates to the SECONDARY cells through the Power Center communication connections. Each cell produces 2.00 pounds of chlorine per 24 hours.

- 521151 IntelliChlor Primary Cell

- 521005 IntelliChlor Secondary Cell

Autopilot Pool Pilot® Professional

The Autopilot Pool Pilot Professional connects up to six cells in series to produce up to 15.72 lbs. of chlorine per day.[4]

The Pool Pilot has a single power supply box for all the cells. It uses special commercial cells.

At the bottom of the manifold is a flow bypass that limits the water flow through the cells.

Autppilot Pool Professional Cells

The Pool Professional uses CC15 cells each which produces 2.62lbs of chlorine/day.[5]

Hayward Saline C Commercial Salt Chlorine Generator

Hayward has chosen to manufacture large SWG cells for commercial pools.[6] The Saline C 6.0 produces 6 lbs/day and the Saline C 11.0 produces 11 lbs/day.

.

.

- ↑ https://www.troublefreepool.com/threads/multiple-cells-in-a-row-or-separate-lines.159208/post-1410204

- ↑ https://www.troublefreepool.com/threads/multiple-cells-in-a-row-or-separate-lines.159208/post-1410332

- ↑ https://www.pentair.com/content/dam/extranet/product-related/product-manuals/commercial/sanitizers/intellichlor/IntelliChlorComSys6%20(520972).pdf

- ↑ https://autopilot.com/product/pool-pilot-professional/

- ↑ https://autopilot.com/wp-content/uploads/2016/10/pool-pilot-professional-brochure.pdf

- ↑ https://www.hayward-pool.com/shop/en/commercial/saline-c-60-c-sasali--1