| Line 9: | Line 9: | ||

[https://hayward-pool-assets.com/assets/documents/pools/pdf/troubleshooting-guides/ProLogic-Troubleshooting-Guide.pdf ProLogic Troubleshooting Guide] is a good place to start with problems. | [https://hayward-pool-assets.com/assets/documents/pools/pdf/troubleshooting-guides/ProLogic-Troubleshooting-Guide.pdf ProLogic Troubleshooting Guide] is a good place to start with problems. | ||

| + | |||

| + | ==SWG Cell Basic Diagnostics== | ||

| + | |||

| + | *Report all readings when you.. | ||

| + | **Go to the diagnostic screen, note the readings and then press the + button to reverse the polarity. | ||

| + | **When the new numbers appear, see what they are. | ||

| + | **Then, press + again and note the new readings. | ||

| + | *What are the first seven characters of the cell and box serial numbers? | ||

| + | *What is the actual salinity and how are you measuring it? | ||

==Configuration Menu-Locked== | ==Configuration Menu-Locked== | ||

Revision as of 19:54, 7 June 2020

Hayward ProLogic

Goldline introduced AquaLogic in 2003. Hayward acquired Goldline in August of 2004. Hayward discontinued AquaLogic in 2008 and replaced it with Prologic.

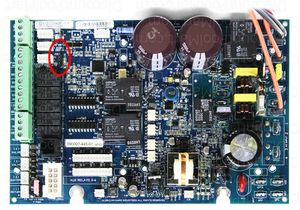

ProLogic uses the GLX-PCB-PRO board.

The Chemistry Sensing Module is a separate system for PH and ORP monitoring and some people fell is a waste of money.[1]

ProLogic Troubleshooting Guide is a good place to start with problems.

SWG Cell Basic Diagnostics

- Report all readings when you..

- Go to the diagnostic screen, note the readings and then press the + button to reverse the polarity.

- When the new numbers appear, see what they are.

- Then, press + again and note the new readings.

- What are the first seven characters of the cell and box serial numbers?

- What is the actual salinity and how are you measuring it?

Configuration Menu-Locked

Press the ‘Menu’ until, ‘Configuration Menu-Locked’ appears. To unlock, press and hold the (<) & (>) keys until the text on the display changes from ‘Locked’ to ‘Unlocked’.

Freeze Protection

The freeze protection temperature is adjustable from 33º F to 42º F (38ºF is the default). Go to configuration and set freeze temperature as you like. Unlock configuration by pressing < > at the same time for 10 seconds.[2]

ProLogic freeze protection uses air temperature, not water temperature. If you are having problems with freeze protection cycling verify that the air and water temperature readings are accurate and that the sensors are not switched (air sensor connected to the water sensor terminal).

Spa Spillover

You can enable the Spa Spillover in the Configuration Menu.

To schedule the spa spillover to run automatically you use a group function assigned to an aux button. But you can only assign one time period to each button.[3]

However if you have two extra buttons available, you can assign different time periods to each while having the same functions.

The only downside to a group function is that it needs to use one of the Aux relays.

CMS comm error

The CSM (Chemistry Sensing Module) comm error appears when Sense & Dispense is enabled, but the Chemistry Sensing Module is not found.[4]

If yes, verify that it's plugged in.

If no, disable Sensing System in the Configuration Menu.[5]

Buttons Become Unresponsive

Usually when the buttons become unresponsive the fix is to replace the display board. Before you buy a new board you can try this repair sort of under Murphy's Laws....go ahead and try it, if you break it you had to replace it anyway:[6]

- Turn off the power to the panel

- Remove SWG cord

- Remove the 3 screws holding on the steel plate

- Remove the display board (it sits on 4 nylon posts) and unplug (be sure to note orientation of wires, I don't think it was keyed)

- Remove the screws holding in the pc board to the display unit and remove it

- "button" pad will then be exposed, carefully peel back and look for discoloration/corrosion on the contacts

- Clean carefully the pc board "contacts" with some q-tips dipped in alcohol

- For heavier oxidation, try a pencil eraser but do not rub too hard - do not scrape with a sharp metal object or sandpaper

- Clean rubber "button" pad with alcohol and let dry before reassembly

- Power it back up and see how you made out

Here is a youtube video on cleaning the contacts for another piece of equipment to give you an idea how to clean the buttons, the principals are the same

- ↑ https://www.troublefreepool.com/threads/hayward-aqua-plus-check-system-light-on.191535/post-1688455

- ↑ https://www.troublefreepool.com/threads/prologic-freeze-protection.108200/post-949302

- ↑ https://www.troublefreepool.com/threads/spillover-question.195423/post-1722887

- ↑ https://www.troublefreepool.com/threads/hayward-goldline-aqua-plus.194999/post-1718637

- ↑ https://www.troublefreepool.com/threads/hayward-aqua-plus-check-system-light-on.191535/

- ↑ https://www.troublefreepool.com/threads/hayward-goldline-aqua-plus-menu-button-no-tworking-on-panel.138410/post-1228214