| (37 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | [[Category:Swimming Pool Equipment]] | ||

| + | |||

=Hayward H-Series Heaters= | =Hayward H-Series Heaters= | ||

| Line 12: | Line 14: | ||

The INSTALLATION, OPERATION, & SERVICE MANUAL for the HXXXFD Series is [https://hayward-pool-assets.com/assets/documents/pools/pdf/manuals/UHS-Service-Installation-011717-RevT.pdf here]. | The INSTALLATION, OPERATION, & SERVICE MANUAL for the HXXXFD Series is [https://hayward-pool-assets.com/assets/documents/pools/pdf/manuals/UHS-Service-Installation-011717-RevT.pdf here]. | ||

| + | |||

| + | Hayward has this YouTube video - [https://www.youtube.com/watch?v=9k5H0JkppYg Universal H Series & ASME Gas Heater Installation, Start-up and Troubleshooting] | ||

Altitude of Installation - Heaters may be installed at any altitude up to 10,100 ft above sea level, provided the appropriate modification(s) are performed. The altitudes which require modification vary depending on the model. Parts necessary to convert the heater for outdoor installation at altitudes up to 7,700 ft (minimum) are included with the heater. More information can be found on page 9 and 10 of the Installation Manual. | Altitude of Installation - Heaters may be installed at any altitude up to 10,100 ft above sea level, provided the appropriate modification(s) are performed. The altitudes which require modification vary depending on the model. Parts necessary to convert the heater for outdoor installation at altitudes up to 7,700 ft (minimum) are included with the heater. More information can be found on page 9 and 10 of the Installation Manual. | ||

| + | |||

| + | Hayward requires the use of a GFCI for their gas heaters. See the [https://www.totallyhayward.com/techservices/attachments/Technical%20Updates%20for%20Pool%20Professionals%20April%202021.pdf 4/14/2021 Technical Updates for Pool Professionals]. | ||

[http://www.haywardnet.com/pdfs/uhs-heater-troubleshooting-guide.pdf Universal H-Series Diagnostics Guide] provides detailed diagnostics for troubleshooting problems and error codes. | [http://www.haywardnet.com/pdfs/uhs-heater-troubleshooting-guide.pdf Universal H-Series Diagnostics Guide] provides detailed diagnostics for troubleshooting problems and error codes. | ||

| + | |||

| + | ===bO Code=== | ||

| + | |||

| + | A bO code is a normal display on the heater display when the heater is being controlled by automation. It indicates the heater is in remote control mode. | ||

| + | |||

| + | To put your heater in bypass you: | ||

| + | |||

| + | #Press the Mode button to place the heater in Standby Mode | ||

| + | #Hold the Down Arrow and Mode buttons simultaneously for 3 seconds for Bypass operation. “bO” will be displayed on the screen | ||

| + | #Heater must then be in the Spa or Pool Mode for operation. The heater will fire when instructed by the external control. | ||

| + | |||

| + | |||

| + | To remove your heater from bypass mode you: | ||

| + | |||

| + | #Press and hold the DOWN key and | ||

| + | #Then press and hold the MODE key | ||

| + | #Hold down both keys for 3 seconds until the indication ‘‘bO’’ is removed from the display. | ||

| + | |||

| + | ===LO Code=== | ||

| + | |||

| + | A Hayward LO code is a limit string open error that occurs when any of the safety circuits on your Hayward pool heater opens. This forces the heater to shut down to protect your heater from damage. | ||

| + | |||

| + | Usual reason for the LO code is lack of sufficient flow not closing the Water Pressure Switch. Low water pressure can be due to a filter that needs to be cleaned, low pump RPM if a VS pump, open heater bypass valve, low skimmer water level, or even a stuck weir door. | ||

| + | |||

| + | Also on the Limit String is the Temperature Limit Switch, Exhaust Gas Temperature Limit Switch, and Vent Pressure Switch. | ||

| + | |||

| + | See pages 40-43 in the [http://www.haywardnet.com/pdfs/uhs-heater-troubleshooting-guide.pdf Universal H-Series Diagnostics Guide]. | ||

| + | |||

| + | ===IF Fault=== | ||

| + | |||

| + | IF, ignition failure, usually means it attempted to light and the flame went out. It will try three times and then give you the IF code. Could be as simple as a bad flame sensor. On the FD units, the flame sensor is a separate sensor and sometimes you can use steel wool or a small steel/diamond file to clean it and it will work.<ref>https://www.troublefreepool.com/threads/if-on-hayward-350fdn.205831/post-1812695</ref> | ||

| + | |||

| + | The flame is sensed in current (microamps or uA) in what is called DC but is really a highly dampened AC Sine wave. The AC Sine wave is dampened because of the large difference in the area of the flame sensor (small area) and the grounding area (large area).<ref> https://www.troublefreepool.com/threads/haywardh250fdn-if-code-that-wont-stop.264550/post-2315467 </ref> | ||

| + | |||

| + | The flame sensor should be cleaned with steel wool or a small steel/diamond file because cleaning with sandpaper or emery cloth can leave residue that will impede conductance. On the other side (ground side) all surfaces from the burner back to case ground must be clean bare metal (as the flame signal is sensed through the flame). This includes the burners and burner slots which can be cleaned with a wire brush and any other metal to metal surfaces back to case ground which may have lost conductance due to dirt/corrosion/oxidation. This would include orifices ( if the burners are hung directly on the orifices ), burner brackets and any other metal to metal breaks that occur between the burners and the case ground. | ||

| + | |||

| + | If the grounding surface is reduced through dirt/corrosion/oxidation you are reducing the difference in area between the flame sensor and ground and the current can no longer be read as DC (highly dampened AC). | ||

| + | |||

| + | If you need to check the flame current you can use a meter that will read micro amps DC by removing the flame sensor from the circuit board and placing the meter in series from the flame sensor wire to the flame sensor post on the circuit board. | ||

| + | |||

| + | ===CE Code=== | ||

| + | |||

| + | CE code on the display indicate a display failure. Water gets in around the display and causes the keypad to be non-responsive. The thread [https://www.troublefreepool.com/threads/design-flaw-in-hayward-pool-heaters-causing-ce-error-codes.214570/ Design Flaw in Hayward Pool Heaters Causing CE Error Codes] goes deeper into the problem and its causes. The fix is an expensive replacement of the display boards. | ||

| + | |||

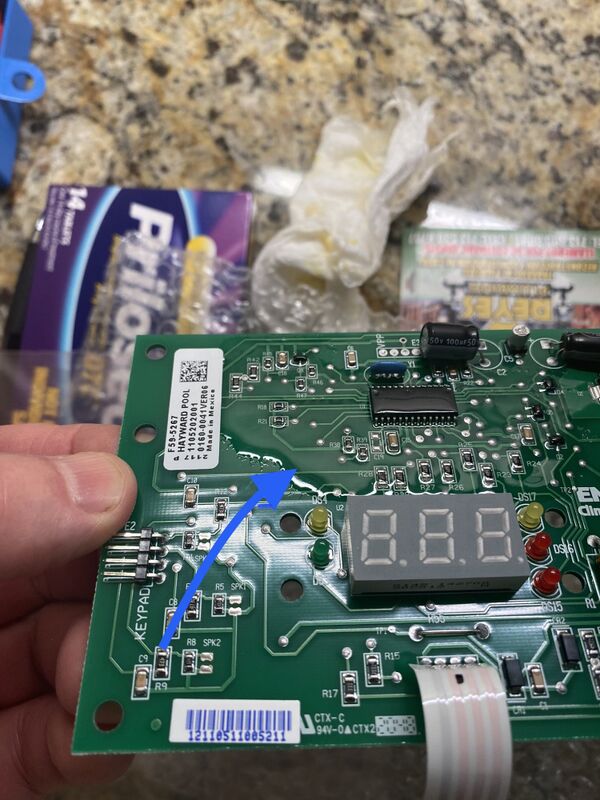

| + | A replacement display board arrived with part of the board having a soft raised are that was bubbled.<ref>https://www.troublefreepool.com/threads/is-this-new-heater-board-part-defective.242806/#post-2127957</ref> That’s a conformal coating and it’s purpose is to waterproof the components that it it applied over. It’s too bad more pool equipment suppliers don’t apply this on their PC boards as it prevents corrosion damage (due to electrolysis) when water gets on energized electronics. It looks like they coated the microprocessor and nearby components. | ||

| + | |||

| + | [[File:Hayward H-Series Display Board.jpg|600px|frameless]] | ||

| + | |||

| + | That is what a normal conformal coated board should look like. | ||

| + | |||

| + | ===SF Code=== | ||

| + | |||

| + | SF code is failure of the temperature sensor. Turn off power to heater and also turn off your pump. Remove the top and bottom side panel as well as the two front panels. | ||

| + | |||

| + | [[File:Hayward H-Series SF Error Thermistor.jpg|thumb]] | ||

| + | |||

| + | Check the sensor wiring and connections for kinks or rodent damage. Inspect terminals for breakage or corrosion. Remove the thermistor and examine the wiring. | ||

| + | |||

| + | If the wiring looks good then replace the temperature sensor. Check that you are getting the correct sensor for your model heater as there are different sensors for the low nox heaters and IDL heaters. | ||

| + | |||

| + | ===Failure To Stay Lit=== | ||

| + | |||

| + | If the heat goes out within a few seconds of coming on you can have a clogged orifice, very left hand one, at the ignition and flame sense area. Spiders seem to like that orifice. Turn gas off at the external gas valve. Remove the gas pipe to the main valve, remove the 4 screws holding the manifold in place, examine all the orifices.<ref>https://www.troublefreepool.com/threads/hayward-heater-f400fdn-problem.266285/post-2330076</ref> | ||

| + | |||

| + | If you see a clog, remove the orifice (3/8" or 7/16" wrench, depending on what Hayward installed) and push the clog backward out of the orifice. If you don't remove the orifice the clog will just move to another area. | ||

| + | |||

| + | These are the easiest manifolds to remove and replace. While it is easier if you remove the wires from the main valve, you don't have to if you are careful. If you do, take a cell-phone picture first to put them back where the belong. | ||

| + | |||

| + | Be sure to use a bit of thread sealant when reassembling the gas line EXCEPT on the union. Make that very tight. Do not tighten the pipe into the main valve beyond where the old sealant shows, you can crack that valve if you overtighten. Use some soapy water to check for leaks. If not comfortable working on gas plumbing, hire a pro. | ||

| + | |||

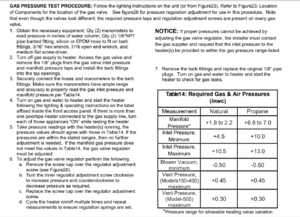

| + | ===Hayward HXXXFD Gas Pressure Test Procedure=== | ||

| + | |||

| + | See page 24 in [https://www.hayward-pool.com/assets/documents/pools/pdf/manuals/UHS-Manual-Rev-C.pdf Hayward UHS INSTALLATION, OPERATION, & SERVICE MANUAL] | ||

| + | |||

| + | [[File:Hayward HXXXFD Gas Pressure Test Procedure.png|thumb]] | ||

| + | |||

| + | ===Transformer=== | ||

| + | |||

| + | The transformer converts the field supply voltage (either 240 VAC or 120 VAC) to a 120 VAC output for blower and igniter power, and a 24 VAC output for powering the ignition control board, control circuits, and gas valve. | ||

| + | |||

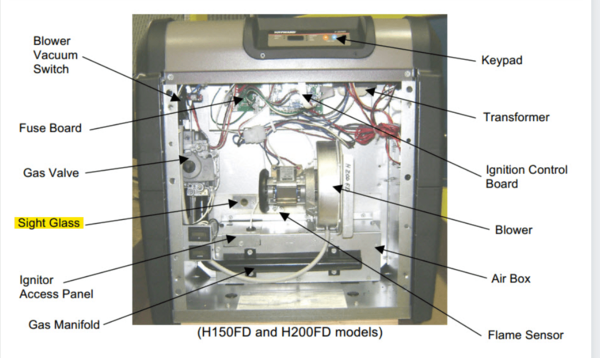

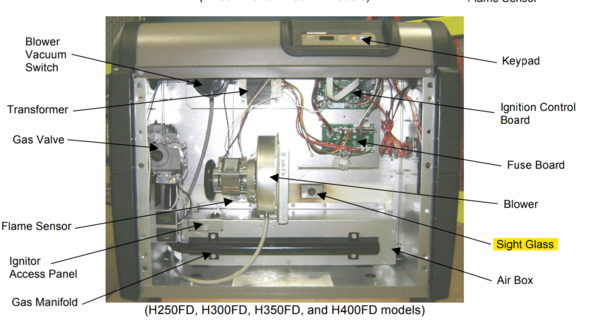

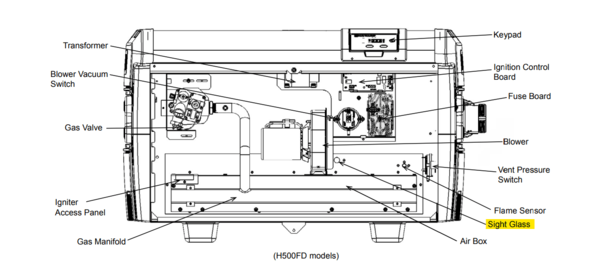

| + | ===HXXXFD Components=== | ||

| + | |||

| + | [[File:Haywood H150FD-H200FD Heater Interior.png|600px|frameless|Hayward H150FD-H200FD Heater]] | ||

| + | |||

| + | [[File:Haywood H250FD-H400FD Heater Interior.png|600px|frameless|Hayward H250FD-H400FD Heater]] | ||

| + | |||

| + | [[File:Hayward H500FD Heater Interior.png|600px|frameless|Hayward H500FD Heater]] | ||

==HXXXIDL Models== | ==HXXXIDL Models== | ||

| Line 34: | Line 127: | ||

Sea Level/high altitude installation - The H-Series IDL heaters may be installed up to 2,000 feet of elevation above sea level. | Sea Level/high altitude installation - The H-Series IDL heaters may be installed up to 2,000 feet of elevation above sea level. | ||

| + | |||

| + | ===Hayward HXXIDL Ignition Problems=== | ||

| + | |||

| + | Its important to check for spider nests in the orifices, especially the one on the far left, right at the igniter on an IDL heater. Usually if that one is blocked the heater won't light, but it could, but the flame-sense rod won't see flame and you could have the problem. The manifold on an IDL heater is the easy to remove and replace.<ref>https://www.troublefreepool.com/threads/hayward-heater-problems-no-error-codes.266056/post-2328575</ref> | ||

| + | |||

| + | Remove the gas line from the main gas valve. This will require closing the external gas valve, opening any union in the line, unthreading pipe from the main gas valve. There will be about 6 screws that hold the manifold in place. A 5/16" socket or nut driver will easily remove and replace those. You will need either a 3/8" or 7/16" wrench to remove any clogged orifices (Hayward used different sizes occasionally so have both available). Always remove the clogged orifice and push whatever is blocking it out toward the back. Us a copper wire, a toothpick, small twig, so as to not scratch the orifice. You don't want to push the debris into the manifold, it will just move and block somewhere else. | ||

| + | |||

| + | On reassembling, be sure to use some pipe sealant for gas, a small tube of RectorSeal #5 is about $4-5. Be sure the union is tight, no sealant is used. After you get it all assembled, turn the external valve on and check for leaks with a bit of soapy water at each joint you disturbed. You will see how far the pipes were threaded into the fittings by whatever was used to seal initially. Use that as a guide. It is especially important to not get too tight going into the main gas valve in the heater, it will crack and need to be replaced. Always leave at least three threads showing outside any fitting. | ||

| + | |||

| + | This probably sounds harder than it really is, but if you are not comfortable working on gas plumbing, call a pro. That is the safest way if you are not the DIY type. Most likely, the tech that checks your gas pressure could do this if the gas pressure is not the issue. | ||

| + | |||

| + | ===Hayward HXXIDL Yellow Burner Flame=== | ||

| + | |||

| + | The flame should be blue not yellow. | ||

| + | |||

| + | Yellow flame indicates too little air or too much gas. It is burning rich which causes for sooting. Likely cause is the burners are "burned" through, the slots are either too large now or there are areas that the slots have broken out and the flame is too large. | ||

| + | |||

| + | Hayward heaters have very thin burner tubes with hundreds of slots in them. When they are burned through you get that yellow flame. The slots near the ends, especially the end closest to the front of the heater cabinet, are usually still a good reference for how large they should be. Its the ones toward the middle and back of the burners that usually wear out the most.<ref?https://www.troublefreepool.com/threads/hayward-h250idl2-overheating.287101/post-2517595</ref> | ||

==HXXX Models== | ==HXXX Models== | ||

| Line 48: | Line 159: | ||

The HXXX models use a natural draft and do not have an air blower. | The HXXX models use a natural draft and do not have an air blower. | ||

| + | |||

| + | Sea level/high altitude installation - The early H-Series heaters may be installed up to 2000 feet of elevation above sea level. For elevations from 2000 to 4500 feet above sea level, heater shall be a high altitude model which has a suffix “H” in the heater model designation (Example: Model H400H1). For elevations above 4500 feet, consult Hayward Customer Service. | ||

| + | |||

| + | By now any of these HXXX series heaters are old and are rarely worth repairing. Even in their day they had consistent problems and poor performance. If you have one of these heaters and it is working then continue to run it often. Spiders love to lay eggs in the heater orifices and running it cooks them out and extends the life of the heater. | ||

| + | |||

| + | ===Lighting Pilot in Millivolt Heater=== | ||

| + | |||

| + | Normal sequence for lighting the millivolt (MV) pilot would be to turn the gas valve knob to the "pilot" position and push it down to allow gas flow to the pilot. While holding the gas valve knob down, push the piezoelectric " spark generator" button multiple times until you observe a pilot flame.<ref> https://www.troublefreepool.com/threads/pilot-light-wont-stay-lit.205931/post-1811792</ref> | ||

| + | |||

| + | Keep holding the gas valve knob down for about 2 minutes. At this time ( after 2 minutes ) you can use a multimeter to measures the output of the thermopile in DC millivolts (the part that sits in the pilot flame and has 2 electrical leads attached to the gas valve ). It should measure 325 MV or above with no load. If it doesn't measure 325 MV or above, replace the thermopile. | ||

| + | |||

| + | ==How Much Gas Does A Heater Use?== | ||

| + | |||

| + | That is a tough question to answer on an individual basis since it varies from pool to pool based on:<ref>https://www.totallyhayward.com/techservices/attachments/Technical%20Updates%20for%20Pool%20Professionals%20%20October%202020.pdf</ref> | ||

| + | *How big is the pool? | ||

| + | *How warm do you want it? | ||

| + | *Where is it located (both locally, and geographically) | ||

| + | |||

| + | What we can answer is how much gas does the heater use per hour of operation. A few facts: | ||

| + | #Hayward heaters are sized based on the amount of input gas they need per hour in BTU’s. Example: A H250FDN needs 250,000 BTU’s of natural gas input to it per hour of operation, and a H250FDP needs 250,000 BTU’s of propane gas input to it per hour of operation. | ||

| + | #A BTU or British Thermal Unit is the amount of heat necessary to raise the temperature of one pound of water one degree. | ||

| + | #Natural gas has a BTU rating of 1037 BTU’s per cubic foot. Put another way there are 100,000 BTU’s in a Therm of natural gas. This is the way it is sold. | ||

| + | #Propane has 91,000 BTU’s per gallon which is the way it is sold. | ||

| + | |||

| + | With these facts in mind we can calculate how much gas a heater will use per hour of operation. | ||

| + | |||

| + | For the H250FDN we mention above the heater will require 2.5 therms of gas per hour of operation. | ||

| + | |||

| + | For the H250FDP the heater will require ~2.75 gallons per hour of operation. | ||

| + | |||

| + | A H500 heater will require exactly twice as much gas per hour, but will also deliver twice as much heat per hour, so the cost per btu is the same. | ||

| + | |||

| + | One last bit of math.... | ||

| + | If you have a 18,000 gallon pool and you want to raise the temperature in the pool from 70 to 85 you will need: | ||

| + | *(18,000 gallons X 8.34 pounds per gallon) 150,120 BTU’s per degree, | ||

| + | *or 150,120 X 15 degree temperature rise = 2,251,800 BTU’s to bring the temperature up the desired 15 degrees | ||

| + | |||

| + | Hayward heaters are 84% efficient and that means you get 84% of the BTU’s that you put into the heater added to the pool water. So the H250 with an input of 250,000 BTU’s actually puts 210,000 BTU’s into the water per hour. | ||

| + | |||

| + | Discounting heat loss (which there is always some) if you are using a Hayward gas heaters to heat the 18,000 gallon pool we have discussed above you will need: | ||

| + | *22.58 therms of natural gas | ||

| + | *24.75 gallons of propane | ||

| + | *To raise the pool water temperature 15 degrees | ||

| + | |||

| + | These numbers hold true no matter which heater size you choose since the number of BTU’s needed does not change. | ||

| + | |||

| + | What will change is how fast the pool is heated! | ||

| + | *For the H250 to heat the pool 15 degrees (again discounting heat loss) it would have to run for 10.71 hours | ||

| + | *If you were using a H400 it would take 6.7 hours | ||

| + | |||

| + | Time to heat would not change between natural gas and propane heaters | ||

Latest revision as of 00:07, 7 January 2024

Hayward H-Series Heaters

Hayward has been producing different models of gas heaters under the H-Series label. It can be confusing when you have a problem and find information talking about a Hayward heater but not your specific model.

Universal H-Series

The Universal H-Series consist of the HXXXFDN, HXXXFDP, W3HXXXFDN, and W3XXXFDP models. N denotes Natural Gas, and P denotes propane gas. FD means the heater is Forced Draft using a blower to create air flow.

The H models are Hayward's EXPERT LINE products that are only available through your local pool professional. The W3H models are available through other channels. I believe they are functionally identical and the only difference will be Hayward's warranty.

Cupro nickel is the standard heat exchanger on the Universal H-Series gas heaters. Cupro nickel heat exchangers last longer than standard copper and superior corrosion resistance protects the heat exchanger from damage and premature failure caused by unbalanced water chemistry.

The INSTALLATION, OPERATION, & SERVICE MANUAL for the HXXXFD Series is here.

Hayward has this YouTube video - Universal H Series & ASME Gas Heater Installation, Start-up and Troubleshooting

Altitude of Installation - Heaters may be installed at any altitude up to 10,100 ft above sea level, provided the appropriate modification(s) are performed. The altitudes which require modification vary depending on the model. Parts necessary to convert the heater for outdoor installation at altitudes up to 7,700 ft (minimum) are included with the heater. More information can be found on page 9 and 10 of the Installation Manual.

Hayward requires the use of a GFCI for their gas heaters. See the 4/14/2021 Technical Updates for Pool Professionals.

Universal H-Series Diagnostics Guide provides detailed diagnostics for troubleshooting problems and error codes.

bO Code

A bO code is a normal display on the heater display when the heater is being controlled by automation. It indicates the heater is in remote control mode.

To put your heater in bypass you:

- Press the Mode button to place the heater in Standby Mode

- Hold the Down Arrow and Mode buttons simultaneously for 3 seconds for Bypass operation. “bO” will be displayed on the screen

- Heater must then be in the Spa or Pool Mode for operation. The heater will fire when instructed by the external control.

To remove your heater from bypass mode you:

- Press and hold the DOWN key and

- Then press and hold the MODE key

- Hold down both keys for 3 seconds until the indication ‘‘bO’’ is removed from the display.

LO Code

A Hayward LO code is a limit string open error that occurs when any of the safety circuits on your Hayward pool heater opens. This forces the heater to shut down to protect your heater from damage.

Usual reason for the LO code is lack of sufficient flow not closing the Water Pressure Switch. Low water pressure can be due to a filter that needs to be cleaned, low pump RPM if a VS pump, open heater bypass valve, low skimmer water level, or even a stuck weir door.

Also on the Limit String is the Temperature Limit Switch, Exhaust Gas Temperature Limit Switch, and Vent Pressure Switch.

See pages 40-43 in the Universal H-Series Diagnostics Guide.

IF Fault

IF, ignition failure, usually means it attempted to light and the flame went out. It will try three times and then give you the IF code. Could be as simple as a bad flame sensor. On the FD units, the flame sensor is a separate sensor and sometimes you can use steel wool or a small steel/diamond file to clean it and it will work.[1]

The flame is sensed in current (microamps or uA) in what is called DC but is really a highly dampened AC Sine wave. The AC Sine wave is dampened because of the large difference in the area of the flame sensor (small area) and the grounding area (large area).[2]

The flame sensor should be cleaned with steel wool or a small steel/diamond file because cleaning with sandpaper or emery cloth can leave residue that will impede conductance. On the other side (ground side) all surfaces from the burner back to case ground must be clean bare metal (as the flame signal is sensed through the flame). This includes the burners and burner slots which can be cleaned with a wire brush and any other metal to metal surfaces back to case ground which may have lost conductance due to dirt/corrosion/oxidation. This would include orifices ( if the burners are hung directly on the orifices ), burner brackets and any other metal to metal breaks that occur between the burners and the case ground.

If the grounding surface is reduced through dirt/corrosion/oxidation you are reducing the difference in area between the flame sensor and ground and the current can no longer be read as DC (highly dampened AC).

If you need to check the flame current you can use a meter that will read micro amps DC by removing the flame sensor from the circuit board and placing the meter in series from the flame sensor wire to the flame sensor post on the circuit board.

CE Code

CE code on the display indicate a display failure. Water gets in around the display and causes the keypad to be non-responsive. The thread Design Flaw in Hayward Pool Heaters Causing CE Error Codes goes deeper into the problem and its causes. The fix is an expensive replacement of the display boards.

A replacement display board arrived with part of the board having a soft raised are that was bubbled.[3] That’s a conformal coating and it’s purpose is to waterproof the components that it it applied over. It’s too bad more pool equipment suppliers don’t apply this on their PC boards as it prevents corrosion damage (due to electrolysis) when water gets on energized electronics. It looks like they coated the microprocessor and nearby components.

That is what a normal conformal coated board should look like.

SF Code

SF code is failure of the temperature sensor. Turn off power to heater and also turn off your pump. Remove the top and bottom side panel as well as the two front panels.

Check the sensor wiring and connections for kinks or rodent damage. Inspect terminals for breakage or corrosion. Remove the thermistor and examine the wiring.

If the wiring looks good then replace the temperature sensor. Check that you are getting the correct sensor for your model heater as there are different sensors for the low nox heaters and IDL heaters.

Failure To Stay Lit

If the heat goes out within a few seconds of coming on you can have a clogged orifice, very left hand one, at the ignition and flame sense area. Spiders seem to like that orifice. Turn gas off at the external gas valve. Remove the gas pipe to the main valve, remove the 4 screws holding the manifold in place, examine all the orifices.[4]

If you see a clog, remove the orifice (3/8" or 7/16" wrench, depending on what Hayward installed) and push the clog backward out of the orifice. If you don't remove the orifice the clog will just move to another area.

These are the easiest manifolds to remove and replace. While it is easier if you remove the wires from the main valve, you don't have to if you are careful. If you do, take a cell-phone picture first to put them back where the belong.

Be sure to use a bit of thread sealant when reassembling the gas line EXCEPT on the union. Make that very tight. Do not tighten the pipe into the main valve beyond where the old sealant shows, you can crack that valve if you overtighten. Use some soapy water to check for leaks. If not comfortable working on gas plumbing, hire a pro.

Hayward HXXXFD Gas Pressure Test Procedure

See page 24 in Hayward UHS INSTALLATION, OPERATION, & SERVICE MANUAL

Transformer

The transformer converts the field supply voltage (either 240 VAC or 120 VAC) to a 120 VAC output for blower and igniter power, and a 24 VAC output for powering the ignition control board, control circuits, and gas valve.

HXXXFD Components

HXXXIDL Models

The HXXIDL heaters are from early 2000 vintage and were replaced by the Universal H-Series heaters. XXX is the BTU rating of the heater in thousands and IDL means "Induced Draft Low NOx". The Installation, Operation, & Service Procedures for the H250IDL2, H350IDL2 & H400IDL2 can be found here. Troubleshooting begins on page 36.

The IDL models use an air blower for the induced draft. There are apparently 4 different blower parts/kits available for the H400IDL2 heater:[5]

- IDXLBWR1930 - Original model w/240V motor which is listed in the manual

- IDXL2BWR1930 - New model w/120V Jakel motor, used in heaters mfg after 9/20/04, (I'm guessing this is the one I have mine is a Jakel motor which says 115V)

- IDXL2BWR1931 - upgrade kit with yet another new blower w/120V Fasco motor, along with a new control board & vacuum switch - which I'm guessing are needed to make the switch from the Jakel to Fasco motor.

- IDXL2BWR1932 - Newest blower w/120V Fasco motor, does not include new control board & vacuum switch - you would only buy this if your heater already has the 120V Fasco motor in it.

The original blower used in these heaters - model IDXLBWR1930 - was a 240V motor. Then in 9/2004 they updated it with a 120V Jakel motor. And then sometime after that (after S/N (21)130701100532001, according to several websites) they switched again to a 120V Fasco motor. The 120V Fasco motor is different from the older 120V Jakel model. The 120V Jakel motor pulls 1.3A and has a 9.0 MFD capacitor, and the newer Fasco motor uses 1.6A and has a 7.5 MFD capacitor.[6]

The heater is equipped with a Hot Surface Ignition Control System that automatically lights the burners. An external power supply is required to power the control system.

Sea Level/high altitude installation - The H-Series IDL heaters may be installed up to 2,000 feet of elevation above sea level.

Hayward HXXIDL Ignition Problems

Its important to check for spider nests in the orifices, especially the one on the far left, right at the igniter on an IDL heater. Usually if that one is blocked the heater won't light, but it could, but the flame-sense rod won't see flame and you could have the problem. The manifold on an IDL heater is the easy to remove and replace.[7]

Remove the gas line from the main gas valve. This will require closing the external gas valve, opening any union in the line, unthreading pipe from the main gas valve. There will be about 6 screws that hold the manifold in place. A 5/16" socket or nut driver will easily remove and replace those. You will need either a 3/8" or 7/16" wrench to remove any clogged orifices (Hayward used different sizes occasionally so have both available). Always remove the clogged orifice and push whatever is blocking it out toward the back. Us a copper wire, a toothpick, small twig, so as to not scratch the orifice. You don't want to push the debris into the manifold, it will just move and block somewhere else.

On reassembling, be sure to use some pipe sealant for gas, a small tube of RectorSeal #5 is about $4-5. Be sure the union is tight, no sealant is used. After you get it all assembled, turn the external valve on and check for leaks with a bit of soapy water at each joint you disturbed. You will see how far the pipes were threaded into the fittings by whatever was used to seal initially. Use that as a guide. It is especially important to not get too tight going into the main gas valve in the heater, it will crack and need to be replaced. Always leave at least three threads showing outside any fitting.

This probably sounds harder than it really is, but if you are not comfortable working on gas plumbing, call a pro. That is the safest way if you are not the DIY type. Most likely, the tech that checks your gas pressure could do this if the gas pressure is not the issue.

Hayward HXXIDL Yellow Burner Flame

The flame should be blue not yellow.

Yellow flame indicates too little air or too much gas. It is burning rich which causes for sooting. Likely cause is the burners are "burned" through, the slots are either too large now or there are areas that the slots have broken out and the flame is too large.

Hayward heaters have very thin burner tubes with hundreds of slots in them. When they are burned through you get that yellow flame. The slots near the ends, especially the end closest to the front of the heater cabinet, are usually still a good reference for how large they should be. Its the ones toward the middle and back of the burners that usually wear out the most.<ref?https://www.troublefreepool.com/threads/hayward-h250idl2-overheating.287101/post-2517595</ref>

HXXX Models

The INSTALLATION, OPERATION, & SERVICE MANUAL for the HXXX Series is here.

The HXXX comes in a millivolt model and an electronic ignition model.

The millivolt heater must be lit manually. The millivolt operated heater is equipped with a standing pilot and a thermopile (pilot generator). All of the electric current required to operate the controls within the heater is provided by the pilot generator. No external wiring or electrical connections are required.

The electronic ignition models are lit automatically on each call for heat. The electronic ignition system is equipped with the same basic controls as the millivolt operated heater but a direct spark ignition device (DS) is used to automatically light the main burners on each call for heat. With the DS module these controls operate on 24 volts so an external power source is required.

The HXXX models use a natural draft and do not have an air blower.

Sea level/high altitude installation - The early H-Series heaters may be installed up to 2000 feet of elevation above sea level. For elevations from 2000 to 4500 feet above sea level, heater shall be a high altitude model which has a suffix “H” in the heater model designation (Example: Model H400H1). For elevations above 4500 feet, consult Hayward Customer Service.

By now any of these HXXX series heaters are old and are rarely worth repairing. Even in their day they had consistent problems and poor performance. If you have one of these heaters and it is working then continue to run it often. Spiders love to lay eggs in the heater orifices and running it cooks them out and extends the life of the heater.

Lighting Pilot in Millivolt Heater

Normal sequence for lighting the millivolt (MV) pilot would be to turn the gas valve knob to the "pilot" position and push it down to allow gas flow to the pilot. While holding the gas valve knob down, push the piezoelectric " spark generator" button multiple times until you observe a pilot flame.[8]

Keep holding the gas valve knob down for about 2 minutes. At this time ( after 2 minutes ) you can use a multimeter to measures the output of the thermopile in DC millivolts (the part that sits in the pilot flame and has 2 electrical leads attached to the gas valve ). It should measure 325 MV or above with no load. If it doesn't measure 325 MV or above, replace the thermopile.

How Much Gas Does A Heater Use?

That is a tough question to answer on an individual basis since it varies from pool to pool based on:[9]

- How big is the pool?

- How warm do you want it?

- Where is it located (both locally, and geographically)

What we can answer is how much gas does the heater use per hour of operation. A few facts:

- Hayward heaters are sized based on the amount of input gas they need per hour in BTU’s. Example: A H250FDN needs 250,000 BTU’s of natural gas input to it per hour of operation, and a H250FDP needs 250,000 BTU’s of propane gas input to it per hour of operation.

- A BTU or British Thermal Unit is the amount of heat necessary to raise the temperature of one pound of water one degree.

- Natural gas has a BTU rating of 1037 BTU’s per cubic foot. Put another way there are 100,000 BTU’s in a Therm of natural gas. This is the way it is sold.

- Propane has 91,000 BTU’s per gallon which is the way it is sold.

With these facts in mind we can calculate how much gas a heater will use per hour of operation.

For the H250FDN we mention above the heater will require 2.5 therms of gas per hour of operation.

For the H250FDP the heater will require ~2.75 gallons per hour of operation.

A H500 heater will require exactly twice as much gas per hour, but will also deliver twice as much heat per hour, so the cost per btu is the same.

One last bit of math.... If you have a 18,000 gallon pool and you want to raise the temperature in the pool from 70 to 85 you will need:

- (18,000 gallons X 8.34 pounds per gallon) 150,120 BTU’s per degree,

- or 150,120 X 15 degree temperature rise = 2,251,800 BTU’s to bring the temperature up the desired 15 degrees

Hayward heaters are 84% efficient and that means you get 84% of the BTU’s that you put into the heater added to the pool water. So the H250 with an input of 250,000 BTU’s actually puts 210,000 BTU’s into the water per hour.

Discounting heat loss (which there is always some) if you are using a Hayward gas heaters to heat the 18,000 gallon pool we have discussed above you will need:

- 22.58 therms of natural gas

- 24.75 gallons of propane

- To raise the pool water temperature 15 degrees

These numbers hold true no matter which heater size you choose since the number of BTU’s needed does not change.

What will change is how fast the pool is heated!

- For the H250 to heat the pool 15 degrees (again discounting heat loss) it would have to run for 10.71 hours

- If you were using a H400 it would take 6.7 hours

Time to heat would not change between natural gas and propane heaters

- ↑ https://www.troublefreepool.com/threads/if-on-hayward-350fdn.205831/post-1812695

- ↑ https://www.troublefreepool.com/threads/haywardh250fdn-if-code-that-wont-stop.264550/post-2315467

- ↑ https://www.troublefreepool.com/threads/is-this-new-heater-board-part-defective.242806/#post-2127957

- ↑ https://www.troublefreepool.com/threads/hayward-heater-f400fdn-problem.266285/post-2330076

- ↑ https://www.troublefreepool.com/threads/hayward-h400idl2-heater-ao-code-bad-blower.92076/post-789236

- ↑ https://www.troublefreepool.com/threads/hayward-h400idl2-heater-ao-code-bad-blower.92076/post-789242

- ↑ https://www.troublefreepool.com/threads/hayward-heater-problems-no-error-codes.266056/post-2328575

- ↑ https://www.troublefreepool.com/threads/pilot-light-wont-stay-lit.205931/post-1811792

- ↑ https://www.totallyhayward.com/techservices/attachments/Technical%20Updates%20for%20Pool%20Professionals%20%20October%202020.pdf