Pump Basics

This Wiki covers the basics of pool pumps. How to select pool equipment discusses other pool equipment.

The US Department of Energy (DOE) shook the pool pump market by implementing Federal Energy Efficiency regulations on Dedicated Purpose Pool pumps (DPPP) as of July 19, 2021. For more information, read Pump DOE Regulations.

People used to select pool pumps based on the pump horsepower to fit the size of the pool and equipment. They advised you that a pump that is too large for the plumbing and equipment could cause damage to the filter and other components and will use more energy than a smaller pump. People used to discuss the turnover times of the pool water, although we now know that turnover does not matter.

Since the US DOE regulations came into effect, almost all pool pumps of 1.1 THP or more are variable speed pumps. Some exceptions exist for low HP, high HP, and specialty pumps. And if you are not in the US then single-speed or 2-speed pumps may still be available.

What Pump Should You Buy?

Using a larger Total Horsepower (THP) pump in a pump family is usually better. It is quieter and more efficient. Unless, of course, you do not care about electrical costs.

A Variable Speed Pump is a variable HP pump. So the concerns about a high HP pump damaging equipment are no longer valid. You run the VS pump at the speed and HP most suitable for your pump and equipment.

Variable-speed pumps are more complex than single or 2-speed pumps. They have electronic control panels to set run times and speeds. Some VS control panels are very basic. Others have advanced controls. If you don't have an automation controller for your VS pump, review the pump's Owner's Manual. You should understand the controls of the pump you are considering.

Pool Automation adds more capabilities to your variable speed pump. It sets the best speed for filtering, skimming, cleaning, and running spa jets and water features whenever needed. If you have or may get, an automation controller, ensure the automation and pump controls are compatible. It usually means the automation and pump should be from the same manufacturer. Even then, their products may be incompatible. Check manufacturer websites and our Wiki pages for the specific automation and pumps you are considering.

Some 1.1THP single-speed pumps are DOE-compliant. However, they are unavailable in all states due to separate state pump regulations (CA, and maybe others). For some small pools and pumped water features, single-speed pumps still work. They can be cheaper and simpler to operate and maintain than VS pumps. Pentair, Jandy, Hayward, and others all have single-speed low HP DOE-compliant pumps.

What Brand Pool Pump?

At its heart, a pump is a commodity product where they are all the same in that they move water. If you want to move water in a simple pool, then a low-cost pump that is disposable when it fails may be all you need.

Pentair, Hayward, and Jandy are the three largest equipment manufacturers. They offer support and warranties if you use their authorized dealers. Their products work with their automation products. They have pump families with different features and horsepower for every price point.

Pentair Pump Catalog 2025-2026 shows you the full range of Pentair pumps.

Hayward cross-reference tool lets you explore pool equipment replacements. This tool helps you find the Hayward replacement options across multiple categories, from pumps and filters to heaters and more.

Waterway, Circupool, Black & Decker, and others have VS pool pumps. They have basic features and maybe simple relay-based automation. But they lack an RS-485 data comm link. These pumps cost less than the major brands. They attract DIY pool owners who don't care about warranties or support.

Many sellers are offering low-cost manufactured pumps online. They may suit price-sensitive pool owners without warranty, support, or spare parts for repairs. Those pumps are probably disposable when they fail.

Regal Rexnord makes many of the pool motors for pump manufacturers. They acquired Regal Beloit, Century Motors, and A.O.Smith Motor Manufacturing.

Choosing Among Pump Families

You are now looking at VS pumps from a major manufacturer. They have a few pump families to consider. What are the major differences, and how do you choose which one suits your pool?

Before the US DOE caused all the pump technical and marketing changes, pool pumps could be classified as:

- High-head pumps for complex equipment with spas, multiple heaters, solar panels, IFCS

- Medium head pumps for basic pools with a filter, SWG, and maybe a heater

- Low-head pumps for water features and fountains

No, we will not get you to calculate the "head" of your pool plumbing. The specific value is not needed. But you can eyeball a pool setup and see if it is a high, medium, or low-head setup. Head is the force/resistance against the pump as it pushes water through your pipes. Filters, heaters, spa jets, In-Floor-Cleaning systems (IFCS), and solar panels all create resistance and add to the plumbing head. This can make a high-head pump more suitable than a medium-head pump.

Manufacturers rarely label whether a pump is a high, medium, or low head in their sell sheets or manuals. Yet, they have organized their pump product line families into those categories:

- ~3 THP variable speed pumps are high-head pumps suitable for pools with heaters, solar, spa jets, in-floor cleaning systems, or other features

- ~1.5 THP variable speed pumps are typically medium head pumps for basic in-ground pools and pools with solar and/or heaters.

- ~1.0 THP variable speed or single speed pumps are typically low-head pumps for smaller pools or water features (1725 RPM).

There are no hard cutoffs on which pump should be used for which environment. An underpowered pump can give you weak flows, while you can slow an overpowered VS pump to get the desired flow. That is why, in general, we recommend getting the 2.7-3HP pumps versus the 1.5HP pumps.

Pump Sizing

Lower flow rates are better for normal circulation and filtering because they are more efficient. However, some water features will need higher flow rates.

- Spa jets usually need 10-25 GPM per jet; with many jets, the pump can need very high flow rates.

- Water features such as waterfalls usually need high flow rates for impressive action.

- In-floor cleaners need relatively high flow rates and high pressure per head to provide enough power for cleaning.

- Suction-side and pressure-side cleaners often need high-head pumps, but depending on the cleaner, they can sometimes run on smaller pumps.

A variable-speed pump is ideal for high and low-flow rate applications. It meets the needs of both. You can use higher speeds when needed and lower speeds when they are not. Operating this way will save energy and money.

Other considerations that are very important when choosing a pump are:

- Above-ground vs. in-ground pumps. Many above-ground pool pumps are not self-priming. They are not suitable for an in-ground pool that needs a self-priming pump.

- Maximum GPM rating for the filter size. Exceeding the flow rate specification for the filter may damage it.

- Minimum GPM rating for heater. Manufacturers will typically specify a minimum GPM for the heater to prevent damage. Also, most heaters have a pressure switch. It won't engage unless the pressure is above a certain threshold.

When designing a new pool, find the maximum flow rate needed for all the features. Then, size the pipe and pump to that flow rate. This will ensure the most energy-efficient design for the pool's requirements.

Pump Impeller

The pump motor turns the impeller, which moves the water through the pump. When you look at an impeller from the edge, you can see the size of the "paddles." The wider the paddle, the more force it takes to move the water. So, you do need to have the impeller properly sized with the motor's HP capability.

The pump impeller's HP rating must always be equal to or less than the motor's HP rating. Too large an impeller for the motor will cause high amperage, overheating, and reduced life.

As you can see in the pictures below, impellers have a larger width as their size increases. The width increases by about 1/16" each time. This moves more water, which increases the load on the motor.[1]

Pump Plumbing

Use high-temperature pump unions to connect pumps to PVC. Some pumps come with the unions, while others do not.

A standard PVC adapter should not be used on pumps, especially the outlet. They are prone to damage from heat generated by a pump running dry. They shrink, leak, and need to be replaced with high-temp unions or a CPVC nipple at the very least.

Pump installation manuals usually recommend that the intake pipe length into the pump be 4x-6x the pipe diameter. This is to provide laminar flow into the pump. With the strainer housing in front of the impeller, it does not matter. If there was no basket and the pipe went straight into the impeller, it would make a difference.

You also have to look at the velocity of the water. The suction should be kept below 6 ft/sec, which will further reduce the importance of the straight pipe requirement.

Manufacturers recommend it but do not require it. There are many pumps with bad installs that operate fine.

Below are some pump cutaways showing the path that the water takes to get to the eye of the impeller. Turbulence in any part of the water flow path decreases efficiency. That’s why there are rules for water velocity and why many designers recommend sweep elbows instead of sharp 90-degree elbows.[2]

The installation diagram above from Jandy recommends a sweep 90 over using a straight pipe in front of the pump. Using sweep elbows helps. Using a straight pipe before the pump helps a little. But do not worry too much about the straight pipe requirement if it takes any significant effort.

Pump Electrical

The NEC requires GFCI circuit breakers for all pool pumps.

The wire to a pool pump should be 14 AWG if connected to a 15-amp circuit breaker or 12 AWG if connected to a 20-amp circuit breaker.

Solid wire is preferable but difficult to run through conduit. Stranded wires can be used with the ends crimped to a ring terminal that goes under the screw. Stranded wire can be looped around the screw so that both sides tighten evenly, although this is not the best connection technique.

Stranded wires should not be slipped under one side of a screw the way solid wire can be connected. Doing so can allow the connection to become loose, causing heat buildup, burning the wire and connection block, as in the pictures below.

Replacing an Old Pump

You are not new to pools, and you got here because your old single-speed or 2-speed pump failed. You have not shopped for a pool pump in many years, and the pool pump market changed with the 2021 US DOE regulations.

If your motor fails and the front wet end of your pump is in good condition, you can replace it. Replacement motors are still available for many single-speed and 2-speed pumps and variable-speed motors. However, consider the electrical cost of running your pump.

As discussed above, the replacement motor HP must always be equal to or greater than the impeller HP. When in doubt, check the part number of the impeller in the pump before replacing the motor.

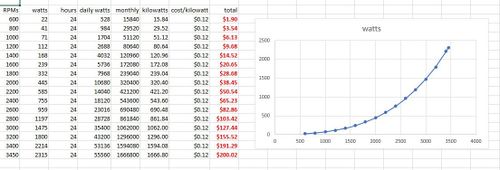

A 1HP pump uses about 1KW of electricity per hour, a 1.5HP pump uses 1.5KW/hour, and a 2HP pump uses 2KW/hour. Depending on your daily pump runtime and your electrical cost per KW hour, you can calculate approximately what your pump is costing you to run.

Jandy Pool Pump Savings Calculator, Pentair Pool Pump Calculator, and Hayward Pump Energy Calculator help you compare a single-speed pump with a VS pump.

Replacing a failed pump with a VS pump, instead of replacing the motor, can pay back in a few years. It depends on your pump runtime, cost/KWH, and electrical savings.

Pump Self Priming

Pumps designed for in-ground pools are self priming, while above ground pool pumps are often not. The reason is above ground pool pumps are usually on the ground below the water line and gravity primes the pump before it runs. An in-ground pool pump may be above or below the water line and it cannot be assumed the pump stays full of water when off.

The seals in a self priming pool pump are designed to run dry for some time without damage as it pulls in air until it primes itself with water. Modern VS pumps can have prime time limits and sense if it fails to prime and automatically shutdown, preventing damage.

A non-self-priming pump can be damaged quickly if run without water in the volute.

It is important to know if a pump is self priming, or not, when starting it up dry. Above ground pool pumps, that are not self-priming, are sometimes installed on in-ground pools.

It is a best practice to prime all pumps, by filling them with water, when they are dry. Priming A Swimming Pool Pump discusses more about pump priming.

Ever wonder how a pump self-primes?

If so, watch this YouTube video on Self-Priming Pump Basics.

And this YouTube video shows you Failure to Prime.

Air in the Pump Basket Under the Lid

A few things can cause air in the pump basket under the lid:

- The pump may not be able to clear all the air in the basket when priming. A dirty filter can cause that, or algae AND a dirty filter. You should clean the filter and do an Overnight Chlorine Loss Test (OCLT) to rule out dirty filter and algae. If you fail the OCLT, follow the SLAM Process to clear the pool.

- Air in the pump basket on low speed (with a 2-speed or Variable Speed Pump (VSP)) may be normal or it can be caused by one of these issues:

- Pump lid leak. Sometimes, pump basket lids will seal better at higher RPM than at lower RPM because the pressure in the pump basket is lower at higher RPM. Lubing the pump lid seals/o-rings and drain plug o-rings can sometimes improve the problem. Use a silicone LUBRICANT, like Magic Lube II.

- Outgassing. The pressure in the pump basket is lower than atmospheric so dissolved gasses in the water can come out of solution. The lower the pressure, the more outgassing that will occur. However, at higher RPM/flow rates, any dissolved air that comes out of solution will quickly get taken out of the pump basket because of the higher flow rate. If the RPM is low enough so the flow rate is lower than the rate at which air rises in the pump basket, the air will remain in the pump basket.

- If you have a VSP, include a short period at high speed every day, and that will clear the bubble.

- Ignore the bubble if your pump never loses prime, even with the air.

- Due to their volute design, Hayward VS pumps seem to have a natural air bubble at low speeds.

- If your pump is set up to only pull from skimmers, a blockage in the suction side (i.e., debris in the suction line, debris in a diverter or valve, hairnets or skimmer socks that are full), water not high enough in the skimmer (it should be 50% up the skimmer opening), or a stuck weir door, you may get air in your pump basket.

- Your impeller may be clogged. Turn off the pump's power at the service disconnect or the breaker, and then you can reach in through the pump basket to see if there is debris. You may have to disconnect the motor from the wet end to determine if you have debris.

- Air in the basket can also be caused by a blockage in the return side of the plumbing, which prevents the pump from purging the air.

- If your issue is not one of the above, then it is highly likely you have a Suction Side Air Leak.

Pump Cavitation

First, let's be clear: cavitation is NOT indicated by the presence of air in a pump basket. An air leak in the suction side of the plumbing causes the air in a pump basket. Cavitation cannot usually be seen. It occurs at the impeller inlet, which is out of view.

Cavitation occurs when water pressure falls below the vapor pressure. The water then boils. However, these vapor bubbles do not last long. As they travel through the impeller, the pressure rises. The bubbles then rapidly collapse, causing a distinct sound like small pebbles in the pump. It is the collapse of the vapor bubbles that can cause impeller damage.

Fortunately, cavitation is rare in pool pumps. It mostly occurs in larger high-head pumps under very high suction conditions.

This YouTube video shows what pump cavitation sounds like.

Pump WEF Rating

The Department of Energy has adopted a metric for rating pumps for their relative efficiency called the Weight Efficient Factor (WEF). Unfortunately, it is not the best way to compare pumps. The reason is in the method of WEF calculation. First, the definition of energy factor:

Energy Factor = GPM * 60 / Watts

For single-speed pumps, this isn't the worst way to compare them (e.g. THP is worse). But the comparison can give wildly different results for pumps with variable speeds. This is why WEF was created, but the methodology has a fundamental flaw. For a VS pump, EF can be calculated at any RPM. The lower the RPM, the higher the EF, down to about 800 RPM. Then it will start to climb again due to the drive electronics' overhead energy use. So the lowest EF is at full speed, which plays into the WEF calculation.

To calculate the WEF of a VS pump, we combine two measurements with a weighting factor for each. The first test is at 80% speed with a 20% weight. The second test is at a lower speed with a specific flow rate (e.g. 31.1 GPM for HHP > 0.75) and an 80% weight. This lowers the WEF for the larger THP VS pumps. In fact, a larger THP VS pump in a pump line may be more efficient at a given flow rate than a lower THP VS pump.

To choose a VS pump, pick the largest THP pump. It should be from your favorite manufacturer or compatible with your controller. When operating the pump, choose the lowest RPM for the task. You will be efficient.

If WEF is not a good metric, how should pumps be compared? In short, we should always compare pump energy consumption at the same flow rate. However, this is not always easy to do as some of the pump databases do not show energy use at specific flow rates. The pump tools spreadsheet linked in Pump Plumbing Head Curves and Operating Points uses this concept. It compares pump energy use at specific flow rates.

Pump Runtimes

You should run the pump for a reason. Consider both speed and duration if you have a VS pump and automation. Reasons for running the pump can be:

- Mix chemicals: Low speed for 1/2 hour is fine for chlorine and acid additions. Salt, calcium, and stabilizer can require more circulation at higher speeds.

- SWG: Clean filter flow off speed + 200RPM, for whatever duration you need for the % output of the SWG.

- Filter: Low speed is better for filtering. Filter long enough so you are happy with the water.

- Skim: Run the lowest speed that get you sufficient skimming. Run for long enough to get the results you want.

- Heater: Run at the speed that gives you enough flow for the heater and run for the duration you need to heat.

- Vacuum: sufficient RPM to operate the vacuum for as long as necessary to clean satisfactorily.

Some of us with VS pumps and a SWG like to run our pump 24/7 at low speed and always add some chlorine to the water.

If you have an In Floor Cleaning Systems, your pump must run much longer at higher speeds.

Past The Pump Basics

Analytical types may want to check pump specs. When choosing a pool pump, look at the pump curve. It shows how flow varies with pressure (head). Pump Plumbing Head Curves and Operating Points explores this in more detail.

When choosing a pump, use the desired flow to calculate the system's resistance (pressure, head, or head loss) at that flow rate.[3]

The point on the pump curve where the pressure and flow intersect is called the operating point. The operating point should be near the middle of the pump curve. Pumps do not perform well near the ends of their curves.

For example, using a WhisperFlo pump (high head) on a fountain (low head) will run it too far right on its curve. This can cause problems like noise, cavitation, and inefficiency. A well-chosen pump, such as a fountain pump, will operate with less noise and greater efficiency.

When choosing a pump, you should look at the maximum head (given in feet) and the maximum flow, as shown by the curve. Then choose a pump that will operate within the limits but not near the limits.

A properly designed system should generally not need high flow or create high head. High head can be created by rooftop solar or in-floor cleaner systems.

The maximum flow needed for a residential pool will usually be due to a big gas heater (400,000 BTU/hr) that might need about 40 to 50 GPM. Besides that, the flow can usually be pretty low (about 20 GPM).

A good choice can be a two-speed or variable-speed pump that runs on low, except during times when higher flow or pressure is needed.

Any new pool should use a variable-speed pump.

If a single-speed pump is used, it should be a maximum of 1.0 total hp.

Pump Repairs

The A.O. Smith CENTURY POOL & SPA MOTOR MANUAL can help you install, maintain, and troubleshoot Century pool and spa motors, which are used by many pool pumps. It details the motor capacitors, how to test them, and other motor repairs.

Century Motor Parts Cross Reference can identify the capacitor, bearings, and other parts to repair a Century or A.O. Smith motor.[4]

Motor Replacement

Many single-speed and two-speed motors are available. Century and Nidec also offer variable-speed motors that can replace single-speed and two-speed motors. The latest Century VGreen EVO motors include Century Connect support and will automatically communicate using RS-485 with Jandy, Pentair, or Hayward automation systems. About 18 months after the introduction of the EVO VS motor, Century changed the motor’s firmware and began advertising its “Century Connect” feature.

Century VGreen EVO motors are available in 1.30, 1.65, and 2.25 THP models with square and c-face flange. Look for the Century Connect label on the packaging:[5]

Bearings

The inyopools guide is in two parts:[6]

- How To Repkace Bearings in a Pool Pump Motor Part I shows you a step by step approach to removing the bearings of your pool pump motor.

- How To Repkace Bearings in a Pool Pump Motor Part II shows you how to replace the bearings and reassemble the motor.

Although this guide is specific to the Hayward Super Pump Motor, many steps are applicable to other brands of motors.

Capacitor

Seals

Centrifugal Switch

Pump Motor Nameplate Definitions

- Nameplate HP (NPHP) - This is the HP rating on the motor nameplate, but it is pretty much meaningless without the service factor.

- Nameplate KW = NPHP * 0.7457 - This is the KW rating and is similar to the nameplate HP and is generally used outside the US. Note that this is not the input power to the motor, only the rating for the motor's output power.

- Service Factor - This is an overload rating for motors which states that the motor can be safely operated over the NPHP by the service factor for short periods. However, for pumps, this overload rating is typically used as the maximum load that a motor would need to deliver to the wet end. Because the load on a pump does not rapidly change over time, the service factor load is often used as the maximum design point for the pump.

- Total HP (THP) or Service Factor HP (SFHP) = NPHP * Service Factor. This is the maximum load that can be safely driven by the motor and must always be greater than the maximum load from the impeller. A motor can be driven above the THP but will likely fail in a short time. Current DOE requires all pumps to now have the THP rating displayed somewhere on the pump.

- Electrical Horsepower (EHP) = Input Watts / 745.7 = Volts * Amps * Power Factor / 745.7 - Electrical power input delivered to the motor.

- Brake Horsepower (BHP) = EHP * Motor Efficiency - Power delivered by the motor shaft to the impeller. This is not the same as THP or SFHP. BHP is a function of the load on the motor shaft and will change with Head, GPM, and RPM.

- Hydraulic HP (HHP) = BHP * Pumping Efficiency = Head (ft) * GPM / 3960 - Power delivered to the water. Sometimes called water HP (WHP) or pumping HP (PHP).

- Motor Power Efficiency = BHP / EHP - I2R, magnetic and mechanical losses in the motor only.

- Pumping Power Efficiency = HHP / BHP - Recirculation and internal friction losses in the wet end only.

- Total Pump Power Efficiency = Motor Efficiency * Pumping Efficiency = HHP / EHP (note this is why total pump efficiency approaches 50%).

- Energy Factor - Gallons/watt-hr = GPM * 60 / Watt-hr; A CEC definition used to quantify a pump's efficiency.

- Service Factor Amps - The amp draw when the motor is loaded to the service factor. Also, multiplying the SF amps by voltage should give a good estimate as to the upper limit for the power draw. However, sometimes the motor is over-dimensioned for the pump so it will not always be an accurate measure of input power. NEMA tolerance for this parameter is ±10%.

- Full Load Amps - This can mean several things depending on the motor manufacturer. It is either the amps at the NPHP or it can be the amps at the THP. You can find it used both ways so unfortunately, there is not a good standard for this one. NEMA tolerance for this parameter is ± 10%.

Other Resources

- How to select pool equipment discusses the other pool equipment you need

- Equipment Pad Best Practices discusses plumbing design and flow rates.

- Determine Pump Runtime discusses the tasks you run your pump to accomplish.

- Pump Plumbing Head Curves and Operating Points discusses how pump curves can be used for pump selection.

- ↑ https://www.troublefreepool.com/threads/keep-blowing-pump-motors-pool-guy-says-call-electrician.305537/post-2668090

- ↑ https://www.troublefreepool.com/threads/pump-inlet-minimum-straight-length.233248/post-2043997

- ↑ https://www.troublefreepool.com/threads/jandy-stealth-vs-flo-pro.175354/post-1547348

- ↑ https://www.troublefreepool.com/threads/motor-bearings.306335/post-2672948

- ↑ https://www.troublefreepool.com/threads/century-connect-automation-support-for-vgreen-evo.279984/#post-2454153

- ↑ https://www.troublefreepool.com/threads/motor-bearings.306335/post-2672950