| Line 144: | Line 144: | ||

*[[Equipment Pad Best Practices]] discusses plumbing design and flow rates. | *[[Equipment Pad Best Practices]] discusses plumbing design and flow rates. | ||

*[https://www.troublefreepool.com/blog/2019/01/18/determine-pump-run-time/ Determine Pump Runtime] discusses the tasks you run your pump to accomplish. | *[https://www.troublefreepool.com/blog/2019/01/18/determine-pump-run-time/ Determine Pump Runtime] discusses the tasks you run your pump to accomplish. | ||

| − | *[[Pump Plumbing Head Curves and Operating Points]] discusses how | + | *[[Pump Plumbing Head Curves and Operating Points]] discusses how pump curves can be used for pump selection. |

Revision as of 21:18, 11 October 2024

Pump Basics

The pool pump market was turned upside down when the US Department of Energy (DOE) implemented Federal Energy Efficiency regulations, as of July 19, 2021, on Dedicated Purpose Pool pumps (DPPP). For more about that read Pump DOE Regulations.

It used to be that pool pumps were selected based on the pump horsepower to fit the size of the pool and equipment. You were advised a pump which is too large for the plumbing and equipment could cause damage to the filter and other components and will use more energy than a smaller pump. Turnover times of the pool water used to be discussed although we now know that turnover does not matter.

Since the US DOE regulations came into effect almost all pool pumps of 1.1 THP or more are variable speed pumps. There are some exceptions for low HP, high HP, and specialty pumps. And if you are not in the US then single speed or 2-speed pumps may still be available.

What Pump Should You Buy?

It is nearly always advantageous to go with a larger Total Horse Power (THP) VS pump in a pump family for both lower noise and greater electrical energy efficiency unless electrical cost does not matter to you.

A Variable Speed Pump is a variable HP pump. So the concerns about a high HP pump damaging equipment are no longer valid. You run the VS pump at the speed and HP most suitable for your pump and equipment.

Variable speed pumps are more complex then single speed or 2-speed pumps with electronic control panels to set run times and speeds. Some VS control panels can be very rudimentary while others can have sophisticated controls. If you will not have an automation controller controlling your VS pump you should review the pump Owners Manual and understand the controls of a pump you are considering.

Pool automation expands the utility and efficiency of a variable speed pump by setting the optimum pump speed for filtering, skimming, cleaning, and running spa jets and water features during the day. If you have an automation controller or may get one in the future you must ensure the automation and pump controls are compatible. Usually that means the automation and pump should be from the same manufacturer and even then manufactures may have incompatibilities between their products. Check manufacturer websites and our Wiki pages for the specific automation and pumps you are considering.

There are still some 1.1THP single speed pumps that are DOE compliant but not available in all States due to separate State pump regulations (CA, and maybe others). For some small pools, pumped water features, and other situations, single speed pumps still make sense. They can be lower cost and simpler in operation and maintenance then VS pumps. Pentair, Jandy, Hayward, and others all have single speed low HP DOE compliant pumps.

What Brand Pool Pump?

At it's heart, a pump is a commodity product where they are all the same in they move water. If you want to move water in a simple pool then a low cost pump that is disposable when it fails may be all you need.

Pentair, Hayward, and Jandy are the big three equipment manufactures. They offer you support and warranties if you go through their authorized dealer channels and compatibility with their automation products. They have multiple pump families with various features and horsepowers for every price point.

Waterway, Circupool, Black & Decker, and others have VS pool pumps with basic features and maybe rudimentary automation interfaces using relays versus RS-485 data comm link. These pumps are at a lower price point then the major manufactures and are attractive to the DIY pool owner who does not care about warranty and support.

There are many low cost manufactured pumps being sold online. They may be appropriate for the price sensitive pool owner who does not care about warranty or support or spare parts for repairs. Those pumps are probably disposable when they fail.

Regal Rexnord makes many of the pool motors for pump manufactures. Over the years they acquired Regal Beloit, Century Motors, and A.O.Smith motor manufacturing.

Choosing Among Pump Families

So now we have you looking at VS pumps from one of the major manufactures and they have a few different families of pumps. What are the major differences and how do you choose which is suitable for your pool?

Before the US DOE caused all the pump technical and marketing changes pool pumps could be classified as:

- High head pumps for complex equipment with spas, multiple heaters, solar panels, IFCS

- Medium head pumps for basic pools with a filter, SWG, and maybe a heater

- Low head pumps for water features and fountains

No, we are not going to get you to calculate the "head" of your pool plumbing. The specific value is not needed. But you can eyeball a pool setup and see if it is a high, medium, or low head setup. Head being the force/resistance working against the pump as it pushes water through your pipes. Filters, heaters, spa jets, In Floor Cleaning systems (IFCS), solar panels, all create resistance and add to the plumbing head and can make a high head pump more suitable then a medium head pump.

Manufactures rarely label if a pump is high, medium or low head in their sell sheets or manuals. However they have organized their pump product line families into those categories:

- ~3 THP variable speed pumps are high head pumps suitable for pools with heaters, solar, spa jets, in-floor cleaning systems, or other features

- ~1.5 THP variable speed pumps are typically medium head pumps for basic in-ground pools as well as pools with solar and/or heaters.

- ~1.0 THP variable speed or single speed pumps are typically low head pumps for smaller pools or water features (1725 RPM).

There are not hard cutoffs as to which pump should be used for which environment. However, an underpowered pump can leave you with disappointing flows while an overpowered VS pump speed can always be lowered to give you the flow you want. That is why, in general, we recommend getting the 2.7-3HP pumps versus the 1.5HP pumps.

Pump Sizing

For normal circulation and filtering, lower flow rates are generally desirable for higher efficiency. However, there are some water features that will require higher flow rates.

- Spa jets usually require 10-25 GPM per jet and and with many jets can require very high flow rates.

- Water features such as waterfalls usually require high flow rates for impressive action.

- In floor cleaners require fairly high flow rates and high pressure per head to provide enough power for cleaning.

- Suction side and pressure side cleaners often require high head pumps but depending on the cleaner, can sometimes run on smaller pumps.

To satisfy the requirements of both high and low flow rate applications, a variable speed pump is an ideal solution. Higher speeds can be used when needed and lower speeds when it is not. Operating this way will save energy and money.

Other considerations that are very important when choosing a pump are:

- Above ground vs in ground pumps. Many above ground pool pumps are not self-priming and would not be suitable for an in ground pool that requires a self-priming pump.

- Maximum GPM rating for the filter size. Exceeding the flow rate specification for the filter may damage it.

- Minimum GPM rating for heater. Manufactures will typically specify a minimum GPM for the heater to prevent damage. Also, most heaters have a pressure switch which will not engage unless the pressure is above a certain threshold.

When designing a new pool, it best to first determine the maximum flow rate required for all of the features and then size the pipe and pump to that flow rate requirement. This will ensure the most energy efficient design for the requirements of the pool.

Replacing an Old Pump

You are not new to pools and you got here because your old single speed or 2-speed pump failed. You have not shopped for a pool pump in many years and the pool pump market changed with the 2021 US DOE regulations.

If your motor failed and the front wet end of your pump is in good condition you can replace the motor. Replacement motors are still available for many single speed and 2-speed pumps as well as variable speed replacement motors. However, look at what your electrical cost is to run your pump.

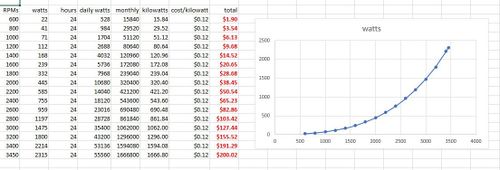

A 1HP pump uses about 1KW or electricity per hour, a 1.5HP pump uses 1.5KW/hour, and a 2HP pump uses 2KW/hour. Depending on your daily pump runtime and your electrical cost/KW hour you can calculate approximately what your pump is costing you to run.

Jandy Pool Pump Savings Calculator, Pentair Pool Pump Calculator, and Hayward Pump Energy Calculator help you compare a single speed pump with a VS pump.

Replacing a failed pump with a VS pump instead of replacing the motor can have a payback in a few years based on your pump runtime, cost/KWH, and the electrical savings.

Pump Cavitation

First, let's be clear, cavitation is NOT indicated by the presence of air in a pump basket. That is caused by an air leak in the suction side of the plumbing. Cavitation cannot usually be directly observed because it occurs at the impeller inlet which is blocked from view.

Cavitation occurs when the water pressure drops below the vapor pressure and the water boils. However, these vapor bubbles do not exist for very long and as they travel through the impeller, the pressure rises and the bubbles rapidly collapse causing a very distinct sound much like small pebbles traveling through the pump. It is the collapse of the vapor bubbles which can cause impeller damage.

Fortunately, cavitation is pretty rare in pool pumps and occurs mostly in larger high head pumps under very high suction conditions.

Pump WEF Rating

The Department of Energy has adopted a metric for rating pumps for their relative efficiency called the Weight Efficient Factor (WEF) and unfortunately, it is not the best way to compare pumps. The reason is in the method of WEF calculation. First, the definition of energy factor:

Energy Factor = GPM * 60 / Watts

For single speed pumps, this is a not the worst way to compare pumps (e.g. THP is worse) but when comparing pumps that can operate at multiple speeds, the speed at which you compare the pumps can give wildly different results. This is why WEF was created but there is a fundamental flaw in the methodology. For a VS pump, EF can be calculated at any RPM and the lower the RPM, the higher the EF down to about 800 RPM and then it will start to climb again due to the drive electronics overhead energy use. So the lowest EF is at full speed which plays into the WEF calculation.

In order to calculate WEF of a VS pump, two measurements are combined with a weighting factor for each. One measurement is performed at 80% of full speed with a 20% weight while the second measurement is performed at a lower speed with a specific flow rate (e.g. 31.1 GPM for HHP > 0.75) and a 80% weight. So what this does in effect is to lower the WEF for the larger THP VS pumps when in fact the larger THP VS pump in a particular pump line may actually have better efficiency at a given flow rate than the lower THP VS pump. So the best way to choose a VS pump is to pick the largest THP pump in the product line of your favorite manufacture or compatible with your controller. Then when operating the pump, choose the lowest RPM for the given task and you will be operating efficiently.

So if WEF is not a good metric to use, how should pumps be compared. In short, pump energy consumption use should always be compared at the same flow rate. But his is not always easy to do as some of the pump databases do not show energy use at specific flow rates. The pump tools spreadsheet linked to in Pump Plumbing Head Curves and Operating Points makes use of this concept to compare pump energy use at specific flow rate conditions.

Past The Pump Basics

For the analytical types who want to look more into pump specifications, when selecting a pool pump you want to look at the pump curve, which shows how the flow varies with pressure (head). Pump Plumbing Head Curves and Operating Points explores this in more detail.

When choosing a pump, the desired flow is used to calculate how much resistance (pressure, head or head loss) will be generated by the system at that flow rate.[1]

The point on the pump curve where the pressure and flow intersect is called the operating point. The operating point should be near the middle of the pump curve. Pumps do not perform well near the ends of their curves.

For example, if a WhisperFlo pump (high head) is used on a fountain (low head application), the pump will run too far to the right on its curve, which can cause multiple problems like noise, maybe cavitation and it's very inefficient. A properly chosen pump, like a fountain pump, will be quieter and more efficient.

When choosing a pump, you should look at the maximum head (given in feet) and the maximum flow as shown by the curve. Then choose a pump that will operate within the limits but not near the limits.

A properly designed system should generally not need high flow or create high head. High head can be created by rooftop solar or in-floor cleaner systems.

The maximum flow usually needed for a residential pool will usually be due to a big gas heater (400,000 btu/hr) that might require about 40 to 50 gpm. Other than that, the flow can usually be pretty low (about 20 gpm).

A two speed or variable speed pump that runs on low except during times where higher flow or pressure is required can be a good choice.

Any new pool should use a variable speed pump.

If a single speed pump is used, it should be a maximum of 1.0 total hp.

Pump Motor Nameplate Definitions

- Nameplate HP (NPHP) - This is the HP rating on the motor nameplate but is pretty much meaningless without the service factor.

- Nameplate KW = NPHP * 0.7457 - This is the KW rating and is similar to the nameplate HP and is generally used outside the US. Note that this is not the input power to the motor only the rating for the output power of the motor.

- Service Factor - This is an overload rating for motors which states that the motor can be safely operated over the NPHP by the service factor for short periods of time. However, for pumps, this overload rating is typically used as the maximum load that a motor would need to deliver to the wet end. Because the load on a pump does not rapidly change over time, the service factor load is often used as the maximum design point for the pump.

- Total HP (THP) or Service Factor HP (SFHP) = NPHP * Service Factor. This is the maximum load that can be safely driven by the motor and must always be greater than the maximum load from the impeller. A motor can be driven above the THP but will likely fail in a short period of time. Current DOE require all pumps to now have the THP rating displayed somewhere on the pump.

- Electrical Horsepower (EHP) = Input Watts / 745.7 = Volts * Amps * Power Factor / 745.7 - Electrical power input delivered to the motor.

- Brake Horsepower (BHP) = EHP * Motor Efficiency - Power delivered by the motor shaft to the impeller. This is not the same as THP or SFHP. BHP is a function of the load on the motor shaft and will change with Head, GPM and RPM.

- Hydraulic HP (HHP) = BHP * Pumping Efficiency = Head (ft) * GPM / 3960 - Power delivered to the water. Sometimes called water HP (WHP) or pumping HP (PHP).

- Motor Power Efficiency = BHP / EHP - I2R, magnetic and mechanical losses in the motor only.

- Pumping Power Efficiency = HHP / BHP - Recirculation and internal friction losses in the wet end only.

- Total Pump Power Efficiency = Motor Efficiency * Pumping Efficiency = HHP / EHP (note this is why total pump efficiency approaches 50%).

- Energy Factor - Gallons/watt-hr = GPM * 60 / Watt-hr; A CEC definition used to quantify a pump's efficiency.

- Service Factor Amps - The amp draw when the motor is loaded to the service factor. Also, multiplying the SF amps by voltage should also give a good estimate as to the upper limit for power draw. However, sometimes the motor is over dimensioned for the pump so it will not always be an accurate measure of input power. NEMA tolerance for this parameter is ±10%.

- Full Load Amps - This can mean several things depending on the motor manufacture. It is either the amps at the NPHP or it can be the amps at the THP. I have seen it both ways so unfortunately, there is not a good standard for this one. NEMA tolerance for this parameter is ± 10%.

Other Resources

- How to select pool equipment discusses the other pool equipment you need

- Equipment Pad Best Practices discusses plumbing design and flow rates.

- Determine Pump Runtime discusses the tasks you run your pump to accomplish.

- Pump Plumbing Head Curves and Operating Points discusses how pump curves can be used for pump selection.