From everything I have read, the main causes of high limit 2 errors are reduced or restricted water flow, which can be from your pump or filter, the unitherm governor and the internal bypass. If you are getting the error that quickly, your problem sounds different than mine. If you do not have proper circulation of water, then the water being measured by the sensors may get too hot very quickly without being pumped through. The UG is easy to replace. The bypass takes 20 minutes or so, but is still as easy fix. Also check your filter pressure first.

My issue seems to occur right when the water is about to hit maximum temperature, and it seems to only happen on hot days. I am speculating that the exhaust air (very hot) is getting into the sensor area and causing the sensor to think the water below is over 135 (when it is only 104 ish). The real hot weather my end today so Im interested to see if the problem continues.

Check this thread too...

Just installed my new heater. It keeps tripping the high limit 2 switch. I think it’s a 135 degree trip. I put a thermocouple on that switch and noticed that if the side cover is off, it runs 120 - 128 degrees. If I put the cover back on it runs 127 - 137 degrees and trips. Why would it run...

www.troublefreepool.com

And this one...

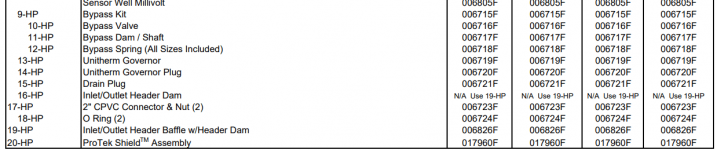

Today I changed the internal bypass too. No high limit errors today but we will see if this is a final fix. The old bypass had rusted and the spring looked stuck (see photo). I have now: 1) replaced both high limit sensors and added thermal paste 2) replaced unitherm governor 3) replaced...

www.troublefreepool.com