Water in J-Box

- Thread starter LynnOnTheWeb

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 65,062

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

You can install two check valves to help prevent water from getting to the blower.

Where should the two CVs be placed?

What kind of CV's - spring or flapper?

How many lb for the spring CV?

Maybe create a drop leg to help give the blower more distance from the check valve.

I would do it like this and use clear PVC pipe so that you can see any water accumulating.

www.pvcfittingsonline.com

www.pvcfittingsonline.com

I would do it like this and use clear PVC pipe so that you can see any water accumulating.

2" Clear Schedule 40 PVC Pipe - 5 ft.

We have clear PVC pipe like this 2" Clear Schedule 40 PVC Pipe - 5 ft.. Available now at super low prices! Save on all your clear PVC fittings too! We sell single 5 foot sections now!

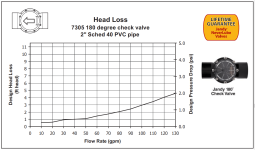

Two or three Jandy check valves should work.

You don't want to create too much resistance because the blower will be significantly reduced in capacity and maybe down to zero or overheat.

You don't want to create too much resistance because the blower will be significantly reduced in capacity and maybe down to zero or overheat.

Each blower has a specified maximum back pressure and a performance chart for Cubic Feet Per Minute vs. Back Pressure.

If the back pressure exceeds the maximum, the blower will either not work at all or it will overheat.

Air gets hot as it is compressed and the blowers also generate a lot of heat, so the air should not be over compressed due to too much back pressure.

40” water = 1.45 psi (3.33 feet).

50” water = 1.8 psi (4.17 feet).

60” water = 2.17 psi (5 feet).

So, a spring check valve will probably be too much back pressure for most blowers.

www.jandy.com

www.jandy.com

Notes: Standard Cubic Feet per Minute (SCFM) is the flow rate of a gas or air through a compressor at standard temperature and pressure conditions.

Standard cubic feet per minute measures the flow rate of gas under standard pressure and temperature conditions.

The accepted standard values for temperature and pressure are 68 degrees Fahrenheit and 36 percent humidity at sea level.

If the back pressure exceeds the maximum, the blower will either not work at all or it will overheat.

Air gets hot as it is compressed and the blowers also generate a lot of heat, so the air should not be over compressed due to too much back pressure.

40” water = 1.45 psi (3.33 feet).

50” water = 1.8 psi (4.17 feet).

60” water = 2.17 psi (5 feet).

So, a spring check valve will probably be too much back pressure for most blowers.

Pool & Spa Blower: Jandy Air Blower | Jandy

Looking for a Pool & Spa Blower? Find the Jandy Air Blower for the Perfect Pool Experience. Buy Now w/ a Pool Pro Near You!

www.jandy.com

www.jandy.com

Notes: Standard Cubic Feet per Minute (SCFM) is the flow rate of a gas or air through a compressor at standard temperature and pressure conditions.

Standard cubic feet per minute measures the flow rate of gas under standard pressure and temperature conditions.

The accepted standard values for temperature and pressure are 68 degrees Fahrenheit and 36 percent humidity at sea level.

I’m trying to do the calculation but this seems way over my head.

I‘ve got a 1.5 HP, 240v, PSB215. That means I have 50” for max back pressure. On step 2 I don’t cross the line until around 60, but the 1.5 HP dotted line doesn’t cross there at all.

@JamesW Should I just test it with the drawing you made? Blower on the right, correct?

I‘ve got a 1.5 HP, 240v, PSB215. That means I have 50” for max back pressure. On step 2 I don’t cross the line until around 60, but the 1.5 HP dotted line doesn’t cross there at all.

@JamesW Should I just test it with the drawing you made? Blower on the right, correct?

Get everything on GFCI breakers.

You will probably need to replace the blower.

Once the motor gets wet, it's usually ruined.

Sometimes they can be dried out, but it might be a safety risk if anything shorts out.

You will probably need to replace the blower.

Once the motor gets wet, it's usually ruined.

Sometimes they can be dried out, but it might be a safety risk if anything shorts out.

I'll do all of that and report back once it's done. Transparent PVC won't be here til next week.

Maybe drill small hole in PVC at lowest point between blower and check valve for a drain in case anything accumulates.

I’m still waiting on the Jandy check valves for the blower. I should probably cancel the order and get them from another source at this point.Any update on this?

In the meantime I removed the blower and capped off the line and my electrician came out and re-wired where the damage was and he put a GFCI breaker at the main panel.

oldprophet

In The Industry

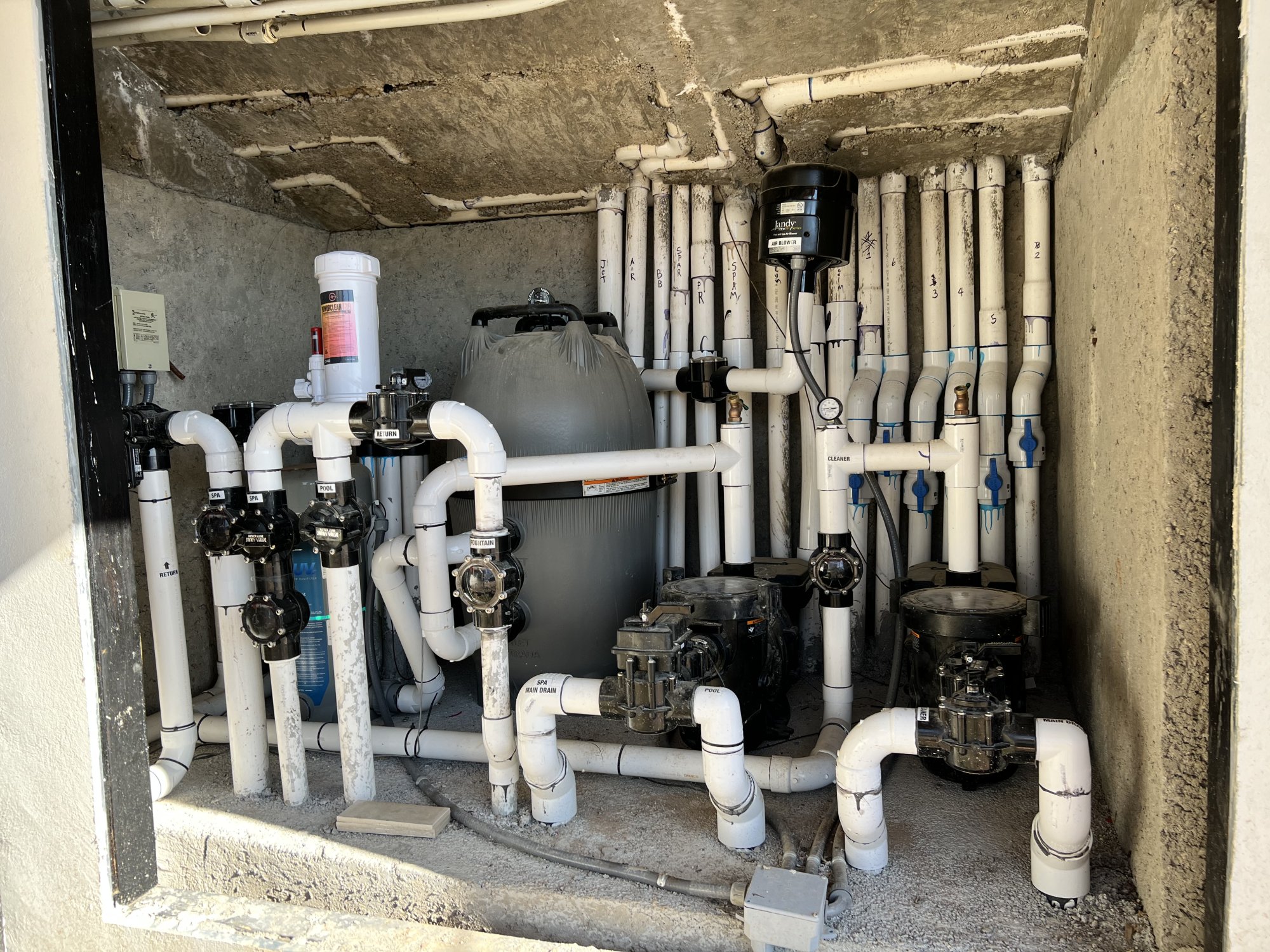

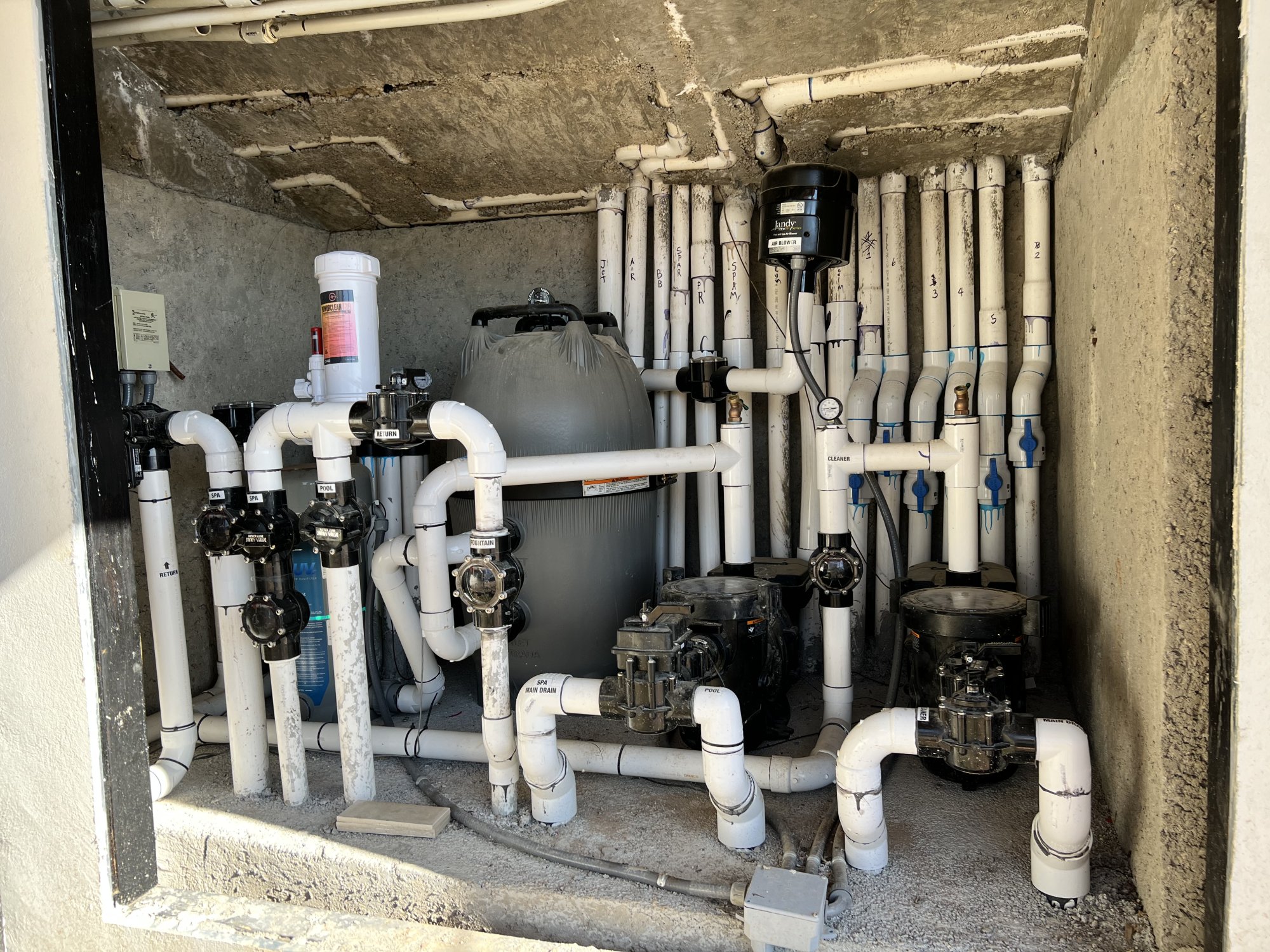

You need to install a Hartford loop in the blower line. I wouldn't trust my life to a check valve.Here's a photo of the entire setup to help you understand the wiring.

RE: seeing if water is coming from pipe. I will double check that at some point but right now the pumps aren't coming on.

Waterway 211-4780.

www.spaparts.com.au

www.spaparts.com.au

Product Description

The best all-in-one air blower protection check valve available!

Waterway 1.5" / 40mm air blower check valve assembly with built in drain valve.

Install horizontally in the air blower loop plumbing

If water manages to get past the built in check valve, it will drain out via a 3/8" (9mm) barb which drains off below a ball float.

This drain valve remains closed in normal operation. if water gets past the check valve it will lift the floating ball and water will drain via the barb.

Connect 9mm clear tubing to the drain barb and run out of the spa cabinet.

1.5" socket towards air injectors

1.5" spigot towards air blower

9mm barb drain.

www.spaparts.com.au

www.spaparts.com.au

Waterway All-In-One Air Blower Check and Drain Valve - Waterway Plastics

Waterway All-In-One Air Blower Check and Drain Valve - Waterway Plastics

Product Description

The best all-in-one air blower protection check valve available!

Waterway 1.5" / 40mm air blower check valve assembly with built in drain valve.

Install horizontally in the air blower loop plumbing

If water manages to get past the built in check valve, it will drain out via a 3/8" (9mm) barb which drains off below a ball float.

This drain valve remains closed in normal operation. if water gets past the check valve it will lift the floating ball and water will drain via the barb.

Connect 9mm clear tubing to the drain barb and run out of the spa cabinet.

1.5" socket towards air injectors

1.5" spigot towards air blower

9mm barb drain.

Waterway All-In-One Air Blower Check and Drain Valve - Waterway Plastics

Waterway All-In-One Air Blower Check and Drain Valve - Waterway Plastics

Waterway Blower Check Valve 600-2900

sunplay.com

sunplay.com

Waterway Blower Check Valve 600-2900

Blower check valve with 1-1/2" slip x 1-1/2" slip fittings

Thanks for this! I finally got the others in but haven’t installed them yet. I might use one of these instead.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.