Variable speed pumps have a maximum speed of 3,450 RPM because the pumps are mostly just the same pumps as the original single speed pumps with a variable speed motor.

These pump designs are decades old and based on system designs that are no longer relevant.

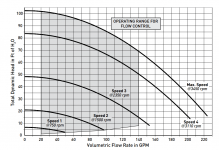

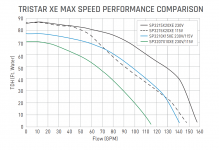

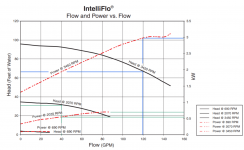

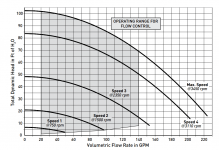

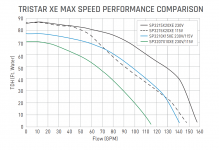

The larger VS pumps can get up to about 90 to 100 feet of head loss, which is completely unnecessary for most system with a good design.

A well designed system should not have a total head loss of more than 50 to 60 feet at the highest flow.

In my opinion, the VS pumps really do not need to have speeds in excess of about 2,450 RPM for most applications.

This would allow the use of a bigger impeller for the same HP pump.

I would suggest that the pumps come in 3 models with maximum speeds of 1,725 RPM, 2,600 RPM and 3,450 RPM.

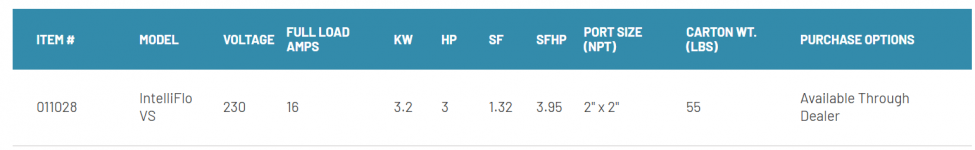

For example, a 3 HP pump with three models with three top speeds can come with a different impeller for each model and this will give 3 different head loss curves.

This will allow the pump to run slower for the same GPM.

This will allow people to choose which head loss curve best fits their system.

The 3,450 RPM will still be available for the people who want that, but it will give the people a choice to have a quieter pump if a lower top speed will work.

These pump designs are decades old and based on system designs that are no longer relevant.

The larger VS pumps can get up to about 90 to 100 feet of head loss, which is completely unnecessary for most system with a good design.

A well designed system should not have a total head loss of more than 50 to 60 feet at the highest flow.

In my opinion, the VS pumps really do not need to have speeds in excess of about 2,450 RPM for most applications.

This would allow the use of a bigger impeller for the same HP pump.

I would suggest that the pumps come in 3 models with maximum speeds of 1,725 RPM, 2,600 RPM and 3,450 RPM.

For example, a 3 HP pump with three models with three top speeds can come with a different impeller for each model and this will give 3 different head loss curves.

This will allow the pump to run slower for the same GPM.

This will allow people to choose which head loss curve best fits their system.

The 3,450 RPM will still be available for the people who want that, but it will give the people a choice to have a quieter pump if a lower top speed will work.