- May 3, 2007

- 18,067

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

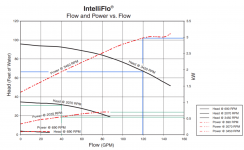

Perhaps, but a manufacture's primary objective is not to reduce cost but to maximize operating margins (cost & revenue) and I suspect the margins are much higher for the larger THP VS pumps than the smaller ones so the actual manufacturing costs may not be that much different. But it would be interesting to see how much of a difference there is in manufacturing costs. Plus, if the manufacture thinks this "new" pump canabalizes sales of their higher margin versions, it is DOA.If you can use a smaller motor, the pump will cost less.