My pool is c. 15000 gallons, and has an adjacent spillover spa. Current equipment is a Hayward Northstar pump rated at 119 gpm with 50-ft head, powered by a 1.5 hp single-speed motor. Filter is a 60 sq ft DE canister. The pump feeds both spa and pool via a T-junction and a valve - one setting returns all water to the spa, another to the pool, and the center position splits the return between the two. The latter is default, so the waterfall from the spa is active and also water returns directly to the pool. The return to the spa has a spring-loaded gate that limits the flow.

I'm thinking of replacing the pump with a variable speed unit, but have a few concerns:

Thanks,

Dave

I'm thinking of replacing the pump with a variable speed unit, but have a few concerns:

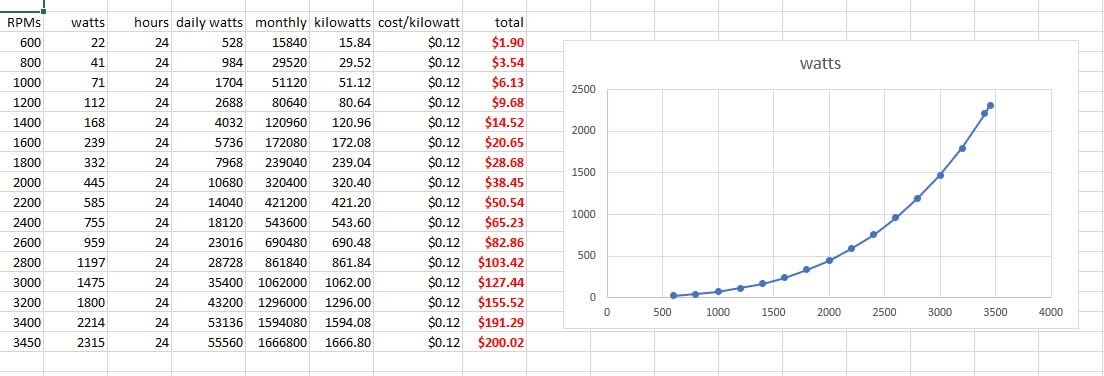

- I see claims for enormous energy savings for a VS pump relative to single-speed; one calculator from Jandy tells me I would save 94% on electricity cost. Most of the claims come from sources trying to sell VS pumps, and many are implausible. As I understand it, assuming you need to circulate a fixed number of gallons daily, a VS pump does it by running at a lower speed for more hours. This is said to be more efficient than a higher speed for fewer hours. This makes sense, but it's hard to believe it's as dramatic as often claimed. Is there any disinterested information available on energy efficiency? (My electricity costs the same at all times, so it's not a factor when the pump is running.)

- Given the spa plumbing, will the lower pressure of a VS pump still work and keep the spillover active?

Thanks,

Dave