Just over a month ago I moved to a new house with a small "indoor" pool in the garden. I knew the pool needed a bit of work and definitely a new liner, but this restoration has snowballed into a much larger project. I'll be documenting the progress as I try to get the pool back to fully working order.

In the garden there is a 6x3m pool (around 25,000 litres) in an enclosed conservatory. This is how it looked shortly after moving in.

I'd always heard that owning a swimming pool was a "money pit", and so far that's definitely what this project feels like. We were in a rush when buying this house and during buying process I didn't get someone in to do a full survey of the pool. This was definitely a mistake. I had tried contacting several pool companies (of which there are very few in the UK).

Here's where I am now

The leak

I was warned the pool needed a new liner and had a minor leak but measuring top-ups (with a LinkTap) I discovered 150 litres was being lost everyday. The liner was in a very poor condition with many repair patches so it was my assumption that it was the main source of the leak. I read a few guides on the best techniques to identify potential sources of leaks so started testing.

Water loss from evaporation? 150 litres definitely seemed like too much. I ordered a new cover and roller to replace the existing one which had suffered a lot of UV damage and was falling apart, and just to eliminate it as an issue. The new cover is an EnergyGuard GeoBubble for use in the colder months with less sun. It'll also reduce excessive humidity in the enclosed space.

I bought some leak dye and looked for leaks around fittings and patches but this didn't show anything obvious.

Next onto checking if things got better or worse without the pump and filter running. No obvious change in the volume of water being lost every 24 hours.

Now blocking the returns, again no change.

A plug in the bottom of the skimmer.

Time to look more carefully and it appeared the pipework in the pump/filter enclosure was leaking in a few different places. Someone had attempted to make a repair to the sand filter which was leaking, along with a small leak from a flexible coupler used on the pipework to connect to a pipe right up against the concrete floor.

It was also clear at this point that the pump was very oversized (1HP) for a pool this size 25m3 / 6,600 US gallons. The small filter was just letting all the dirt straight through thanks to the powerful pump.

I decided I would tackle replacing the pump and filter to eliminate another leak source.

At this point I called several pool companies to get them to quote on

In the garden there is a 6x3m pool (around 25,000 litres) in an enclosed conservatory. This is how it looked shortly after moving in.

I'd always heard that owning a swimming pool was a "money pit", and so far that's definitely what this project feels like. We were in a rush when buying this house and during buying process I didn't get someone in to do a full survey of the pool. This was definitely a mistake. I had tried contacting several pool companies (of which there are very few in the UK).

Here's where I am now

The leak

I was warned the pool needed a new liner and had a minor leak but measuring top-ups (with a LinkTap) I discovered 150 litres was being lost everyday. The liner was in a very poor condition with many repair patches so it was my assumption that it was the main source of the leak. I read a few guides on the best techniques to identify potential sources of leaks so started testing.

Water loss from evaporation? 150 litres definitely seemed like too much. I ordered a new cover and roller to replace the existing one which had suffered a lot of UV damage and was falling apart, and just to eliminate it as an issue. The new cover is an EnergyGuard GeoBubble for use in the colder months with less sun. It'll also reduce excessive humidity in the enclosed space.

I bought some leak dye and looked for leaks around fittings and patches but this didn't show anything obvious.

Next onto checking if things got better or worse without the pump and filter running. No obvious change in the volume of water being lost every 24 hours.

Now blocking the returns, again no change.

A plug in the bottom of the skimmer.

Time to look more carefully and it appeared the pipework in the pump/filter enclosure was leaking in a few different places. Someone had attempted to make a repair to the sand filter which was leaking, along with a small leak from a flexible coupler used on the pipework to connect to a pipe right up against the concrete floor.

It was also clear at this point that the pump was very oversized (1HP) for a pool this size 25m3 / 6,600 US gallons. The small filter was just letting all the dirt straight through thanks to the powerful pump.

I decided I would tackle replacing the pump and filter to eliminate another leak source.

At this point I called several pool companies to get them to quote on

- pressure testing the pipework

- replacing the skimmer (as Kafko parts were going to be difficult to source)

- replacing the main drain (as above)

- replacing the light with an led version

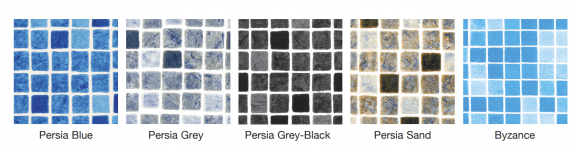

- replacing the liner