Hi Everyone,

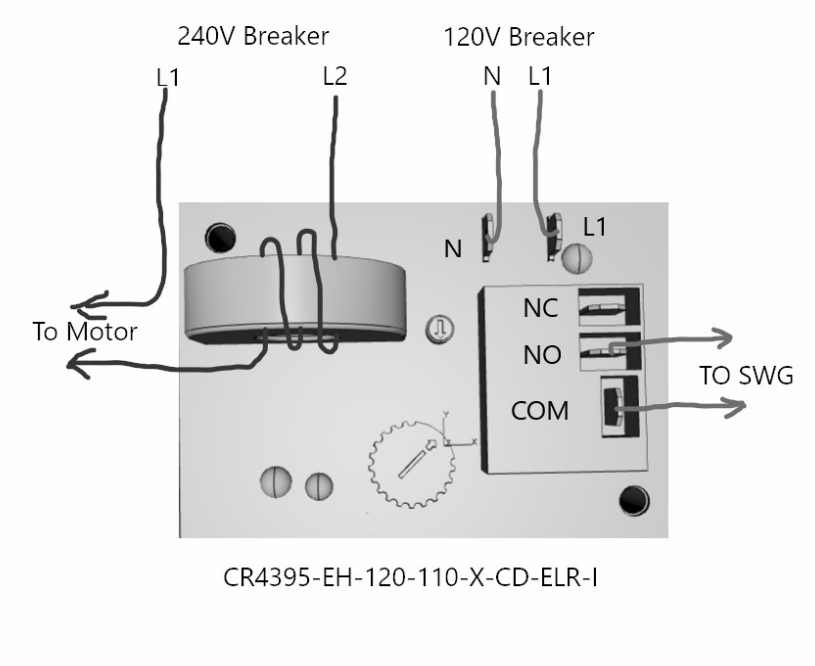

After too much time without a current sensing relay, I finally added one to my system. I know I was living dangerously but life happens and this project fell down the list. Additionally, I struggled with the design limitations of the CR magnetic relays with an operating range of 1-10amps or 3-30, My pump runs from about 0.8 amps up to 6-8 amps, so I could have fallen out of the sensing range.

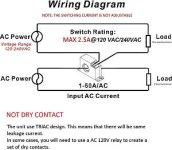

Recently came across a normally open relay that senses 1-50 amps and can handle 2.5 amps on the switching side at 240VAC which is enough power to run the SWG. Instead of a physical contact switch, the unit uses a triac for switching and can bleed current. I'm wondering if anyone has experience with a triac and if the current bleeding will have any long-term negative effects on the SWG electronics. Every time the unit starts and shuts off, it appears like the unit is experiencing a brownout whereas a relay should give a sharp on/off. Any thoughts if the triac will cause electronic issues?

Seems these relays are are often used to trigger dryer blower fans and some models are: Greystone CS-425-HC-5 and fantech ACCS40 to name a few.

Appreciate any thoughts on if this will cause me problems down the road.

After too much time without a current sensing relay, I finally added one to my system. I know I was living dangerously but life happens and this project fell down the list. Additionally, I struggled with the design limitations of the CR magnetic relays with an operating range of 1-10amps or 3-30, My pump runs from about 0.8 amps up to 6-8 amps, so I could have fallen out of the sensing range.

Recently came across a normally open relay that senses 1-50 amps and can handle 2.5 amps on the switching side at 240VAC which is enough power to run the SWG. Instead of a physical contact switch, the unit uses a triac for switching and can bleed current. I'm wondering if anyone has experience with a triac and if the current bleeding will have any long-term negative effects on the SWG electronics. Every time the unit starts and shuts off, it appears like the unit is experiencing a brownout whereas a relay should give a sharp on/off. Any thoughts if the triac will cause electronic issues?

Seems these relays are are often used to trigger dryer blower fans and some models are: Greystone CS-425-HC-5 and fantech ACCS40 to name a few.

Appreciate any thoughts on if this will cause me problems down the road.