Thoughts on my pool equipment install

- Thread starter rocketx2

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 65,473

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

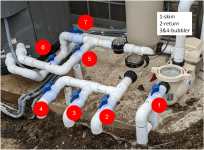

Let's say it is not optimal but you are unlikely to see much of a difference. Having the 90s may require 100 rpm more on the pump then if you didn't have the 90s.Is putting elbows in my system to connect these lines going to be an issue?

I'm worried that having a bunch of 90° turns is bad for the system. Make sense?

View attachment 476308

Sweeps are a better way of doing 90° turns, but actual proper schedule 40 sweeps are rather hard to find (though a plumber/pool builder should have access to them), and anything you'll find in a hardware/big box store is a DWV part. Understanding hydraulics is not exactly my forte, but after reading dozens of threads on here about head, plumbing, and debates over what the Crane TP-410 says, the difference is small enough to probably not matter. I wouldn't start building tons of 180 degree turns with a bunch of 90s, but with 2" piping at swimming pool pressures, it isn't the end of the world. I'd wager 97% of pools in the US are plumbed just like yours.

- Feb 6, 2015

- 7,834

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

The cheap ball valves (instead of proper Jandy valves) and a sketchy heater bypass are more of a long-term concern than a few extra elbows in a pipe run.

Please explain. I'm interested in your insights.The cheap ball valves (instead of proper Jandy valves) and a sketchy heater bypass are more of a long-term concern than a few extra elbows in a pipe run.

Thank you!Let's say it is not optimal but you are unlikely to see much of a difference. Having the 90s may require 100 rpm more on the pump then if you didn't have the 90s.

Thank you!Sweeps are a better way of doing 90° turns, but actual proper schedule 40 sweeps are rather hard to find (though a plumber/pool builder should have access to them), and anything you'll find in a hardware/big box store is a DWV part. Understanding hydraulics is not exactly my forte, but after reading dozens of threads on here about head, plumbing, and debates over what the Crane TP-410 says, the difference is small enough to probably not matter. I wouldn't start building tons of 180 degree turns with a bunch of 90s, but with 2" piping at swimming pool pressures, it isn't the end of the world. I'd wager 97% of pools in the US are plumbed just like yours.

- Feb 6, 2015

- 7,834

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

The ball valves shown over time (a couple years) will get difficult to turn and the handles will get brittle and probably break.

Use Jandy 2-way or 3-way valves instead.

The Jandy valves can be rebuilt if necessary.

Ball valves have to be cut out and replaced.

Use Jandy 2-way or 3-way valves instead.

The Jandy valves can be rebuilt if necessary.

Ball valves have to be cut out and replaced.

+1. The ball valves will break and whether it's on year 3 or 7, the PB will be long gone and you'll be paying top dollar to replace them.

Which one of these valves need to be changed? All of them?The ball valves shown over time (a couple years) will get difficult to turn and the handles will get brittle and probably break.

Use Jandy 2-way or 3-way valves instead.

The Jandy valves can be rebuilt if necessary.

Ball valves have to be cut out and replaced.

Thanks for your insight.

- May 3, 2014

- 62,725

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

All of them, And you are going to want to be able to isolate the bubblers from the returns. You will not want to run the bubblers all the time.

Can't I turn the bubblers off with valves three and four?All of them, And you are going to want to be able to isolate the bubblers from the returns. You will not want to run the bubblers all the time.

Or do I need a valve between valves two and three? Kind of valve 2.5.

- Feb 6, 2015

- 7,834

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

As Marty stated- all of them.

A proper heater bypass should be incorporated as well. As installed, yours requires moving multiple valves instead of just one - and it also can lead to dead-heading your pump.

www.troublefreepool.com

www.troublefreepool.com

What size is the filter? It looks to be a bit small.

A proper heater bypass should be incorporated as well. As installed, yours requires moving multiple valves instead of just one - and it also can lead to dead-heading your pump.

Heater Bypass - Further Reading

What size is the filter? It looks to be a bit small.

- May 3, 2014

- 62,725

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

You can. A lot of intervention each time you run the pool.Can't I turn the bubblers off with valves three and four?

The equipment guy is putting an actuator on the bubbler so I can run them with the Pentair automation.You can. A lot of intervention each time you run the pool.

Do you have a brand of valve you recommend? I know about Jandy Pentair and Haywood period I see some off brands that look similar and are cheaper, are they as good?You can. A lot of intervention each time you run the pool.

- May 3, 2014

- 62,725

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Not with those valves they are not.The equipment guy is putting an actuator on the bubbler so I can run them with the Pentair automation.

I would get Jandy Never Lube valves.Do you have a brand of valve you recommend? I know about Jandy Pentair and Haywood period I see some off brands that look similar and are cheaper, are they as good?

- Jul 21, 2013

- 65,473

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Jandy, Hayward, Pentair, CMP, diverter valves are equally good.Do you have a brand of valve you recommend? I know about Jandy Pentair and Haywood period I see some off brands that look similar and are cheaper, are they as good?

You should get diverter valves from the same manufacturer as the actuators you will use on top of them since different screw threads are used in some. Putting mismatched screws and threads can cause cracking if the screw holes.

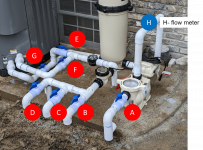

How should my valves be configured?

I'm getting the equipment guy to install all Jandy valves. I have a feeling the way they're configured now isn't optimum.

I'd love to get the groups thoughts on how these vows should be configured.

For example, should I have an outflow port so I could use the pump to lower the water level in the pool?

The heat pump has 3 valves. Is that the way to do it?

Thanks for your insight.

I'm getting the equipment guy to install all Jandy valves. I have a feeling the way they're configured now isn't optimum.

I'd love to get the groups thoughts on how these vows should be configured.

For example, should I have an outflow port so I could use the pump to lower the water level in the pool?

The heat pump has 3 valves. Is that the way to do it?

Thanks for your insight.

- Jul 21, 2013

- 65,473

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

A, B, C, and D are fine.

E, F, and G can be simplified to remove the risk of dead heading the plumbing with a 3 way valve at E & G and a check valve at F. See Heater Bypass - Further Reading

E, F, and G can be simplified to remove the risk of dead heading the plumbing with a 3 way valve at E & G and a check valve at F. See Heater Bypass - Further Reading

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.