I've just bought a second-hand Lanark Cantwell Bay. It's in relatively good condition, and I'm working through the new-owner niggles. It uses an MSPA/Gecko system, Gecko 530AA0540 heater, MSPA main-board whose PCB says it's a "9911-500149 Rev:C" and 10 button control panel.

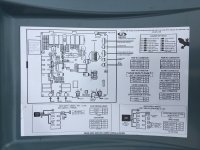

All the jumpers are set to the left, which according to the diagram on the inside of the cover says it is:

JMP1 - Single phase 1 x 32A (yep)

JMP2 - TSC-4 10 Keys (yep)

JMP3 - With blower (yep)

JMP4 - Pump #1 (1 Speed) (Odd - The pump this switches says is is a Elettromeccanica Gambugliano dual speed 2850/1450 rpm on its plate, should this jumper be set to 2 speed?)

JMP5 - Pump #2 (1 speed)

JMP6 - With Pump #3

JMP7 - With Circ Pump (Not sure what a circ pump is, or what it looks like)

JMP8 - Press switch on pump #1 (Not sure what this means)

There are two single speed pumps on the left and right sides, and a dual speed pump which sucks from the filters and pushes into the heater.

My question is...

1. What is the usual purpose of the "Filter Pump" button? I ask because when I press "Filter Pump" does it seem to activate a pump that has nothing to do with the filter (it activates the right hand side single speed pump, mainly neck/back jets)?

2. Why when I have a dual speed pump (that sucks from the filters and pushes into the heater) do none of the pumps seem to have this capability on the control panel (and all jumpers are set to single)?

3. Why does the "Pump #1" button activate the dual speed pump that I would have thought was actually the "Filter Pump"?

4. Do you recommend any product to restore the dials which have yellowed?

TIA

Jason

All the jumpers are set to the left, which according to the diagram on the inside of the cover says it is:

JMP1 - Single phase 1 x 32A (yep)

JMP2 - TSC-4 10 Keys (yep)

JMP3 - With blower (yep)

JMP4 - Pump #1 (1 Speed) (Odd - The pump this switches says is is a Elettromeccanica Gambugliano dual speed 2850/1450 rpm on its plate, should this jumper be set to 2 speed?)

JMP5 - Pump #2 (1 speed)

JMP6 - With Pump #3

JMP7 - With Circ Pump (Not sure what a circ pump is, or what it looks like)

JMP8 - Press switch on pump #1 (Not sure what this means)

There are two single speed pumps on the left and right sides, and a dual speed pump which sucks from the filters and pushes into the heater.

My question is...

1. What is the usual purpose of the "Filter Pump" button? I ask because when I press "Filter Pump" does it seem to activate a pump that has nothing to do with the filter (it activates the right hand side single speed pump, mainly neck/back jets)?

2. Why when I have a dual speed pump (that sucks from the filters and pushes into the heater) do none of the pumps seem to have this capability on the control panel (and all jumpers are set to single)?

3. Why does the "Pump #1" button activate the dual speed pump that I would have thought was actually the "Filter Pump"?

4. Do you recommend any product to restore the dials which have yellowed?

TIA

Jason