looks like 15’ run to the edge of decking then HL, with an accessible check valve, is where the roads are leading. Or run to pad with blower.

Spa/Pool Pipe Size Question after reading Hydraulics 101

- Thread starter markmac

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Are the descents elevated? Could the loop be put in one of those containers? Any rock features you could hide it in?

The descents are in the raised wall on the opposite side of the pool from the Spa. I can run the 2.5” air line under the pool and up into the wall. It would be 15’ across the pool, but it has to go deep and then back up. I figured I wouldnt want that as then the jets have to pull water up 4 or 5 feet vertically. The raised wall will be 2’ Above coping so plenty above spa water level.

if I ran around the edge of the pool, it would be ~30’ to the raised wall corner, but generally at water level.

if I ran around the edge of the pool, it would be ~30’ to the raised wall corner, but generally at water level.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I think you now know why most PBs like to use blowers. It makes the installation easier and less risk.

yes I can. Shortest run I can figure would be 25’ from spa to raised wall keeping pipe at water level.

I read in one of you’re older posts, max safe dist without check valve or blower was 10’? Or does jet selection, velocity, GPM etc also factor in to how much water it can clear?

If I have a check valve within 5’ can the run be 35? As the water is held to 5’ regardless if it’s 10’ run or 50’ run after that.

I’m Leaning towards a check valve within 3-5’, and then run 2.5” to the pad (35’) into a tall HL. That way I have a chance to see if it all works without a blower. If it doesn’t, I pop on the blower at the pad. Hope for the best, prepared for the worst.

I read in one of you’re older posts, max safe dist without check valve or blower was 10’? Or does jet selection, velocity, GPM etc also factor in to how much water it can clear?

If I have a check valve within 5’ can the run be 35? As the water is held to 5’ regardless if it’s 10’ run or 50’ run after that.

I’m Leaning towards a check valve within 3-5’, and then run 2.5” to the pad (35’) into a tall HL. That way I have a chance to see if it all works without a blower. If it doesn’t, I pop on the blower at the pad. Hope for the best, prepared for the worst.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Sounds like a good compromise.

Jet selection does have an effect on the amount of suction that the venturis can generate but so does flow rate. Given the low head loss and total flow rate, I figured you could go a quite a bit longer than my spa. I have 6 jets running at about 15 GPM per jet. Did we discuss jets at all? I have forgotten. How many jets were you planning on and what is the flow rate per jet requirement?

With a check valve, the run can be 100' or perhaps even longer. That is the longest air pipe run I have heard of without a blower but the pipe was 2.5".

But a HL at the pad really doesn't do anything since there is no pipe after that. Just stub out a tall pipe out of the ground. The blower would go on top of that.

Jet selection does have an effect on the amount of suction that the venturis can generate but so does flow rate. Given the low head loss and total flow rate, I figured you could go a quite a bit longer than my spa. I have 6 jets running at about 15 GPM per jet. Did we discuss jets at all? I have forgotten. How many jets were you planning on and what is the flow rate per jet requirement?

With a check valve, the run can be 100' or perhaps even longer. That is the longest air pipe run I have heard of without a blower but the pipe was 2.5".

But a HL at the pad really doesn't do anything since there is no pipe after that. Just stub out a tall pipe out of the ground. The blower would go on top of that.

I was thinking the HL at the pad, but just more to angle the pipe down, more than anything. If it didn’t work, cut the pipe, and add the blower.

I’ve not finalized anything on jets. That’s the next topic, but have been asking plumber subs what they offer, as they have ‘Base Spa ‘ fee that includes all plumbing for spa. I can upgrade to 3”, add more etc. Latest sub said he’d provide whatever jet TEE I wanted

“Nozzle ¼ can get 7 GPM , with 12 PSI, or

½, 5/8, ¾”. Here’s pic he sent over. Looks like Jandy. Is there a preferred line of jets recommended for ease of repair or replacement in the future? I see poly jet mentioned frequently and was looking at their line that had 10 GPM req.

maybe a dumb question, but why would I want jets that need higher flow? Wouldn’t the lowest flow be the best solution, unless I want to be swimming against a current?

I was planning for 6 jets. I figure with the XF VS pump, and 3” lines, I should be okay, and able to run jets at reasonably low RPM? Or can I consider 8?

I’ve not finalized anything on jets. That’s the next topic, but have been asking plumber subs what they offer, as they have ‘Base Spa ‘ fee that includes all plumbing for spa. I can upgrade to 3”, add more etc. Latest sub said he’d provide whatever jet TEE I wanted

“Nozzle ¼ can get 7 GPM , with 12 PSI, or

½, 5/8, ¾”. Here’s pic he sent over. Looks like Jandy. Is there a preferred line of jets recommended for ease of repair or replacement in the future? I see poly jet mentioned frequently and was looking at their line that had 10 GPM req.

maybe a dumb question, but why would I want jets that need higher flow? Wouldn’t the lowest flow be the best solution, unless I want to be swimming against a current?

I was planning for 6 jets. I figure with the XF VS pump, and 3” lines, I should be okay, and able to run jets at reasonably low RPM? Or can I consider 8?

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

The pic on the right is not really for spa jets. You would not have spa jets that big because it would require way too much flow rate. Spa jets are usually 1/4" to 1/2"

The larger the nozzle, the more area that it will hit your back.

Just for reference, I run 6 - 3/8" jets off a 1 HP full rated pump. So you can definitely go larger and with more.

At full speed, the pump and plumbing should be able to support the following:

16 - 1/4" Jets @ 7 GPM each

8 - 3/8" Jets @ 15 GPM each

6 - 7/16" Jets @ 21 GPM each

4 - 1/2" Jets @ 29 GPM each

Each scenario has similar exit velocity which determines the strength of the jet. But the larger jets create a larger impact area.

The larger the nozzle, the more area that it will hit your back.

Just for reference, I run 6 - 3/8" jets off a 1 HP full rated pump. So you can definitely go larger and with more.

At full speed, the pump and plumbing should be able to support the following:

16 - 1/4" Jets @ 7 GPM each

8 - 3/8" Jets @ 15 GPM each

6 - 7/16" Jets @ 21 GPM each

4 - 1/2" Jets @ 29 GPM each

Each scenario has similar exit velocity which determines the strength of the jet. But the larger jets create a larger impact area.

are those calculations all based on the same pump speed assumption?

does any of those provide more pull from the venturi and thus clean the line faster?

i started looking at check valves and then realized I’d need an air check valve, not water. So does the location of the check valve really matter? 5’ from spa, or 20’ from spa? As soon as Water starts to fills the line, it would create a back pressure and close the valve, preventing anymore water entering the line. Or am I missing something?

does any of those provide more pull from the venturi and thus clean the line faster?

i started looking at check valves and then realized I’d need an air check valve, not water. So does the location of the check valve really matter? 5’ from spa, or 20’ from spa? As soon as Water starts to fills the line, it would create a back pressure and close the valve, preventing anymore water entering the line. Or am I missing something?

At full speed, the pump and plumbing should be able to support the following:

16 - 1/4" Jets @ 7 GPM each

8 - 3/8" Jets @ 15 GPM each

6 - 7/16" Jets @ 21 GPM each

4 - 1/2" Jets @ 29 GPM each

i assume I can mix these also. for example, 8 - 1/4” with 4 - 3/8”. maybe try keeping everything under 110 GPM, when considering max flow.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

3450 RPMare those calculations all based on the same pump speed assumption?

The vacuum in a venturi is proportional to the difference in velocity squared of the water streams before and after the nozzle. The velocity of the water stream is related to the flow rate through the jet and the diameter of the jet nozzle. Decreasing the jet nozzle diameter or increasing flow rate will increase velocity.does any of those provide more pull from the venturi and thus clean the line faster?

Venturi effect - Wikipedia

But I believe this is the reason most spas require blowers because the builder did not allocate high enough flow rate for each jet and probably never did any head calculations for verification. This also makes the jets weaker than desirable. Design for high flow rate per jet for strong jets, and you will probably not require a blower except for rare installations where the pad is lower relative to the water level or the air line is really long.

Unless you are looking at something different, those are not really air check valves but check valves for blower air lines. The blower air line check valves are designed to stop water, not air. Pretty much the same as standard pool check valves they just have lower spring tension. But that is what I had assumed you were going to use. The location of the check just determines how much of the pipe will fill with water.i started looking at check valves and then realized I’d need an air check valve, not water. So does the location of the check valve really matter? 5’ from spa, or 20’ from spa? As soon as Water starts to fills the line, it would create a back pressure and close the valve, preventing anymore water entering the line. Or am I missing something?

Unless you are looking at something different, those are not really air check valves but check valves for blower air lines. The blower air line check valves are designed to stop water, not air. Pretty much the same as standard pool check valves they just have lower spring tension. But that is what I had assumed you were going to use. The location of the check just determines how much of the pipe will fill with water.

hmm, maybe I’m not understanding the air line check valve. The check valve is to prevent water from moving backwards through the pipe. When water starts moving backwards, wouldn’t that push air ahead of it, and close the valve?

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

It will close but may not prevent the air from leaking out. It must be air tight to seal and prevent the air from leaking out.

Guess I could always slap an intellivalve on the Pad side of the airline, and have it close when spa mode is off and open when on. Although it’s the same price as just adding a blower then.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

The valve will close much too slowly to be any good. The water will fill the line before the valve can shut off.

As long as the air line isn't too deep, there is a good chance that the venturis will be strong enough to clear the line without a check valve. So if you really don't want a check valve close to spa, and I don't blame you, leave it out and see if it works. If not add the check valve at the pad and see if that works. If not add the blower. That will work.

As long as the air line isn't too deep, there is a good chance that the venturis will be strong enough to clear the line without a check valve. So if you really don't want a check valve close to spa, and I don't blame you, leave it out and see if it works. If not add the check valve at the pad and see if that works. If not add the blower. That will work.

When building the Jet hardware list, what components dictate the flow requirements? Is it the jet itself, or do tee’s orifices need to be selected? I was looking at the Poly Jet hardware and the jets have GPM listings, but then it also has a list for orifice choices for the non-adjustable jets.

I’ve been assuming everything else here I just order for the pipe sizes I want (for the TEE), and then select jets for the desired GPM? When searching jets, I find very few list GPM or the size of the nozzle or orifice.

I’ve been assuming everything else here I just order for the pipe sizes I want (for the TEE), and then select jets for the desired GPM? When searching jets, I find very few list GPM or the size of the nozzle or orifice.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

It is the jet orifce that determines the flow rate requirements.

Lack of GPM specifications is one reason for the numerous postings on unsatisfactory performance of jets. Unfortunately, too often these requirements are ignored by PBs.

Lack of GPM specifications is one reason for the numerous postings on unsatisfactory performance of jets. Unfortunately, too often these requirements are ignored by PBs.

And the jet orifice is in the jet body itself, Correct? Everything else in that diagram can be selected irregardless of the Jet body.

just seems odd that so many jets online don’t seem to list GPM, or the Orifice size. Just the pipe size.

just seems odd that so many jets online don’t seem to list GPM, or the Orifice size. Just the pipe size.

- May 3, 2007

- 16,936

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

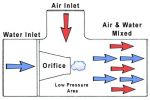

The orifice is a small hole where the water comes out and mixes with the air. This is internal to the venturi tee and deep within the spa wall. The outer fittings such as eyeballs and spinners are really separate from the venturi although some combine them into a single fixture.

View attachment 150072

so this occurs in the Gunite body assembly in this pic? Where the air line has the slot at the bottom.

what makes it confusing is the internal jet says 10 GPM, but there’s nothing referenced for the Gunite body.

For example, Looking at the CMP site, the Gunite body lists pipe sizes, and Jets list the GPM.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.