Hi,

New to this forum and totally new to pools. Do have liquid pumping system experience though.

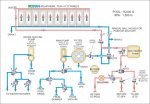

I made a drawing of the pool system in the house we just bought. The question I have is related to shutdown and drainage of the solar panels.

With the solar system off, I opened the two drain valves shown in the drawing and let the panels drain. Then I closed the two manual ball valves to isolate the panels from any flow. When I turned on the main pump (solar diverter valve in the "off" position i.e. no flow to the panels), drain valve 2 in the drawing leaked water. I assume that leakage is because the solar diverter valve gate has an opening to allow the panels to drain when the solar system shuts off. Is that correct? Should that backflow device allow flow both ways or just one-way out of the panels?

Any other comments or hints on the system appreciated.

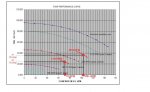

Another question please. What pump speeds would be good for running 1.no solar, 2.with solar and 3.spa only? Thanks.

New to this forum and totally new to pools. Do have liquid pumping system experience though.

I made a drawing of the pool system in the house we just bought. The question I have is related to shutdown and drainage of the solar panels.

With the solar system off, I opened the two drain valves shown in the drawing and let the panels drain. Then I closed the two manual ball valves to isolate the panels from any flow. When I turned on the main pump (solar diverter valve in the "off" position i.e. no flow to the panels), drain valve 2 in the drawing leaked water. I assume that leakage is because the solar diverter valve gate has an opening to allow the panels to drain when the solar system shuts off. Is that correct? Should that backflow device allow flow both ways or just one-way out of the panels?

Any other comments or hints on the system appreciated.

Another question please. What pump speeds would be good for running 1.no solar, 2.with solar and 3.spa only? Thanks.