My '95 Hot Spring Grandee uses 6 of these 30A Potter & Brumfield T92S7D22-12 General Purpose DPST NO relays for controlling just about everything in the tub. Here's a picture of one.

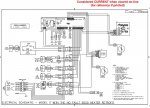

They work great and last forever for running the circ pump, the jet pumps, etc. but running the heater is hard on them. The new heater that Watkins is using (a Hydroquip 6KW) has higher output than the original heater that tub came with and I find I'm having to replace one or both of the relays in the heater circuit (see wiring diagram below) at least once a year. I was paying about $30 CAD each for them plus a little shipping from Digikey but now I see I can get a Schneider Electric one from Mouser for about $17 CAD or ones that appear to be the same P&B relay from Chinese Vendors on eBay for ~$7 or $8 CAD (don't know if they're real or counterfeit though). In the final analysis, it's not really the cost that matters most to me; I just want to have more reliability and less downtime in the heating circuit and I think these relays are a little underdesigned for the loads this new heater puts on them and that's why they're not lasting near as long as they should. Methinks a modification/upgrade to that circuit is in order.

I've been wondering if switching to a higher rated/more robust relay may be the solution to the problem. I've looked to see if anyone makes a 35A or 40A version of that same relay but it seems 30A is as big as anyone makes. I then wondered if I could maybe find solid state relays (SSRs) that could be substituted for the two electro-mechanical relays in the heater circuit but I couldn't find a DPST NO SSR anywhere. What I did find though were these SPST NO 40A SSR relays that you can get cheap on eBay.

I would have to use two of them for each of the two DPST relays that are in the heater circuit now (so 4 in total) so that will take some work but I think there's enough room in the control box to be able to do it. Do you think that could work/solve the reliability problem? What would be the pros and cons of replacing the original electro-mechanical relays with these SSRs? Below is the wiring schematic for the control box.

They work great and last forever for running the circ pump, the jet pumps, etc. but running the heater is hard on them. The new heater that Watkins is using (a Hydroquip 6KW) has higher output than the original heater that tub came with and I find I'm having to replace one or both of the relays in the heater circuit (see wiring diagram below) at least once a year. I was paying about $30 CAD each for them plus a little shipping from Digikey but now I see I can get a Schneider Electric one from Mouser for about $17 CAD or ones that appear to be the same P&B relay from Chinese Vendors on eBay for ~$7 or $8 CAD (don't know if they're real or counterfeit though). In the final analysis, it's not really the cost that matters most to me; I just want to have more reliability and less downtime in the heating circuit and I think these relays are a little underdesigned for the loads this new heater puts on them and that's why they're not lasting near as long as they should. Methinks a modification/upgrade to that circuit is in order.

I've been wondering if switching to a higher rated/more robust relay may be the solution to the problem. I've looked to see if anyone makes a 35A or 40A version of that same relay but it seems 30A is as big as anyone makes. I then wondered if I could maybe find solid state relays (SSRs) that could be substituted for the two electro-mechanical relays in the heater circuit but I couldn't find a DPST NO SSR anywhere. What I did find though were these SPST NO 40A SSR relays that you can get cheap on eBay.

I would have to use two of them for each of the two DPST relays that are in the heater circuit now (so 4 in total) so that will take some work but I think there's enough room in the control box to be able to do it. Do you think that could work/solve the reliability problem? What would be the pros and cons of replacing the original electro-mechanical relays with these SSRs? Below is the wiring schematic for the control box.