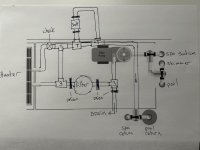

I'm redoing my pad plumbing and trying to decide where to put check valves. I have a pool and spa combo where the spa is above the level of the pool and the level of the spa is also slightly above the pump. The suction side has three lines for the spa, skimmer and main drain. The return has 2 lines for the spa and floor cleaner that goes to the pool. I have a heater, a salt cell, a pump and a filter. The spa return currently has a check valve but if any spa valves are open when the pump is off the spa will drain down to the inlets.

I plan to plumb a heater bypass, so I will install a check valve on the heater outlet before the bypass and the salt cell. Should I keep the spa return check valve? Should I put a check valve anywhere else?

I plan to plumb a heater bypass, so I will install a check valve on the heater outlet before the bypass and the salt cell. Should I keep the spa return check valve? Should I put a check valve anywhere else?