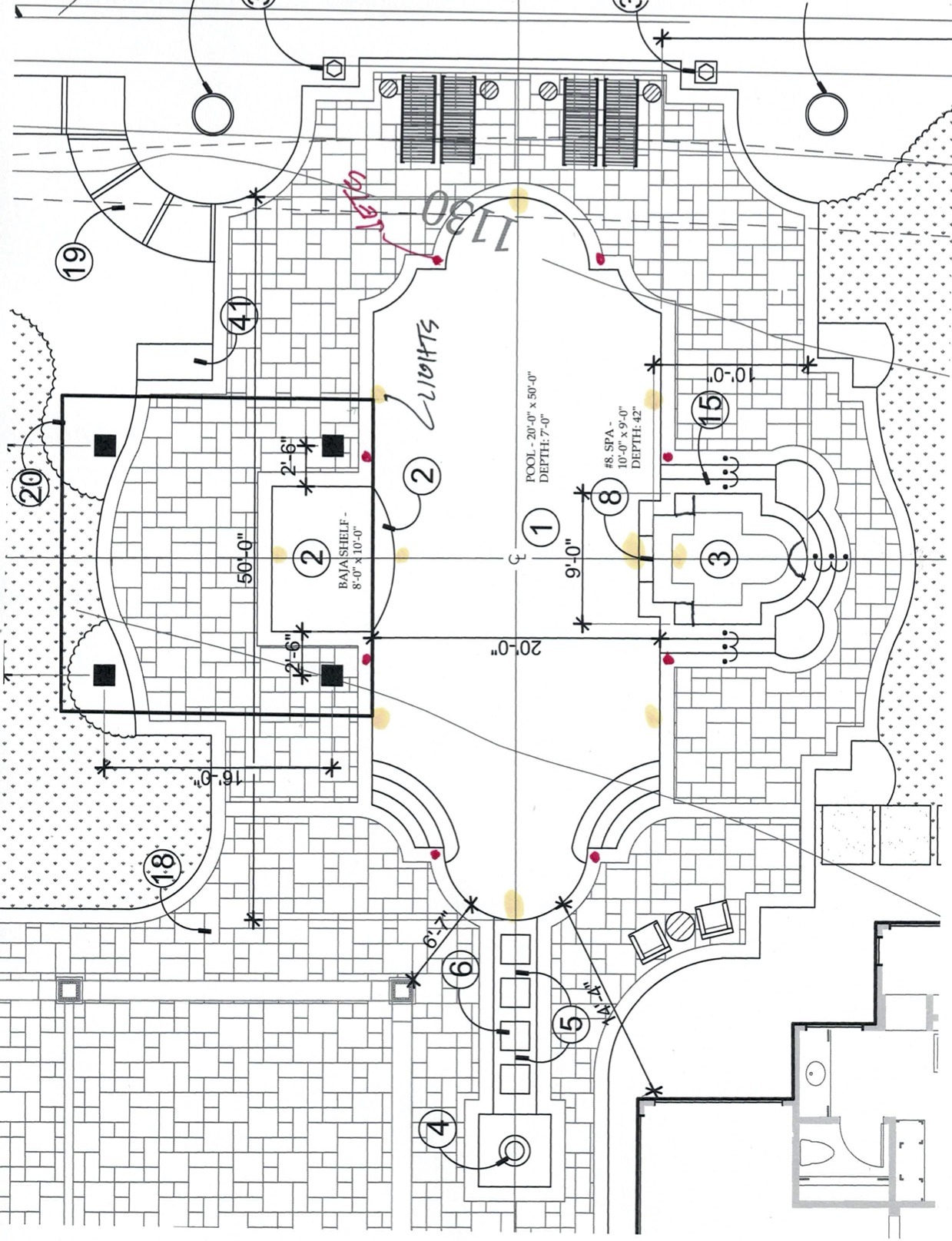

Hi there-pool in So California (see build thread in sig). Lots of radius pieces needed for the coping. Contractor outlines the coping choices as stone, precast concrete or poured in concrete.

Stone--least likely to crack (big concern in SoCal), nicest looking, most expensive because labor intensive to fabricate

Precast--able to match decking (probably travertine), medium cost, middle of the pack in therms of cost.

Pour-in-place concrete--cheapest, most likely to crack.

Any other alternatives I should consider?

Any preferences?

Thinking of going 2' foot pieces to minimize cracking potential.

Stone--least likely to crack (big concern in SoCal), nicest looking, most expensive because labor intensive to fabricate

Precast--able to match decking (probably travertine), medium cost, middle of the pack in therms of cost.

Pour-in-place concrete--cheapest, most likely to crack.

Any other alternatives I should consider?

Any preferences?

Thinking of going 2' foot pieces to minimize cracking potential.