regarding static head of elevated pump, is this only added to Dynamic head on suction side? I know TDH should be lower on suction than return but don’t know how much lower is required to avoid issues.

Static head is added to the suction and subtracted from the return for a net of zero.

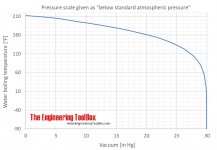

The key for suction is to stay well away from the cavitation point.

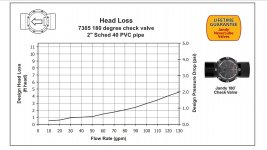

I would use 12 feet as the maximum acceptable suction head loss.

What you lose "pulling" the water up is gained as the water "falls" back to the pool.

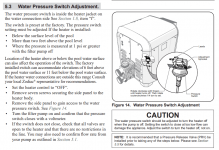

This also creates a problem for the heater pressure switch, which requires about 3 psi to close the switch.

Since the head loss is subtracted from the returns, you need at least 5 psi to close the pressure switch instead of the normal 3 psi.

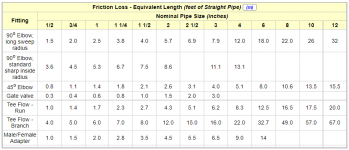

If we use 6 psi as a target head loss for the return after the filter to reliably close the heater pressure switch, that’s about 14 feet of head loss from the exit of the heater to the pool.

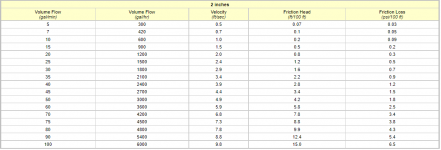

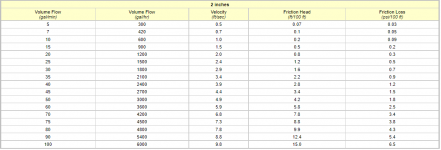

If you have 100 feet 2” PVC from the heater to the pool, you don’t hit 14 feet of head loss until the flow is about 100 gpm.

Even a 400,000 btu/hr heater only requires 40 gpm.

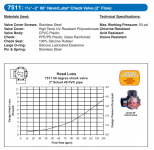

So, unless you install a 40 gpm flow switch instead of the pressure switch, you will have to run the pump much faster than necessary just to make the heater work.

You can install eyeballs on the returns to create extra back pressure, but I would go with a flow switch.

Once the heater goes more than 4 feet above or below the water level, I would recommend adding a flow switch set to the correct required gpm instead of the pressure switch.

A 400,000 btu per hour heater requires a minimum of 40 gpm.

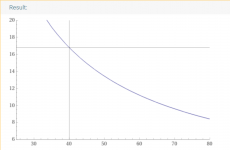

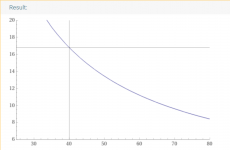

Below is the temperature rise for a 400,000 btu per hour heater vs. flow in gpm.