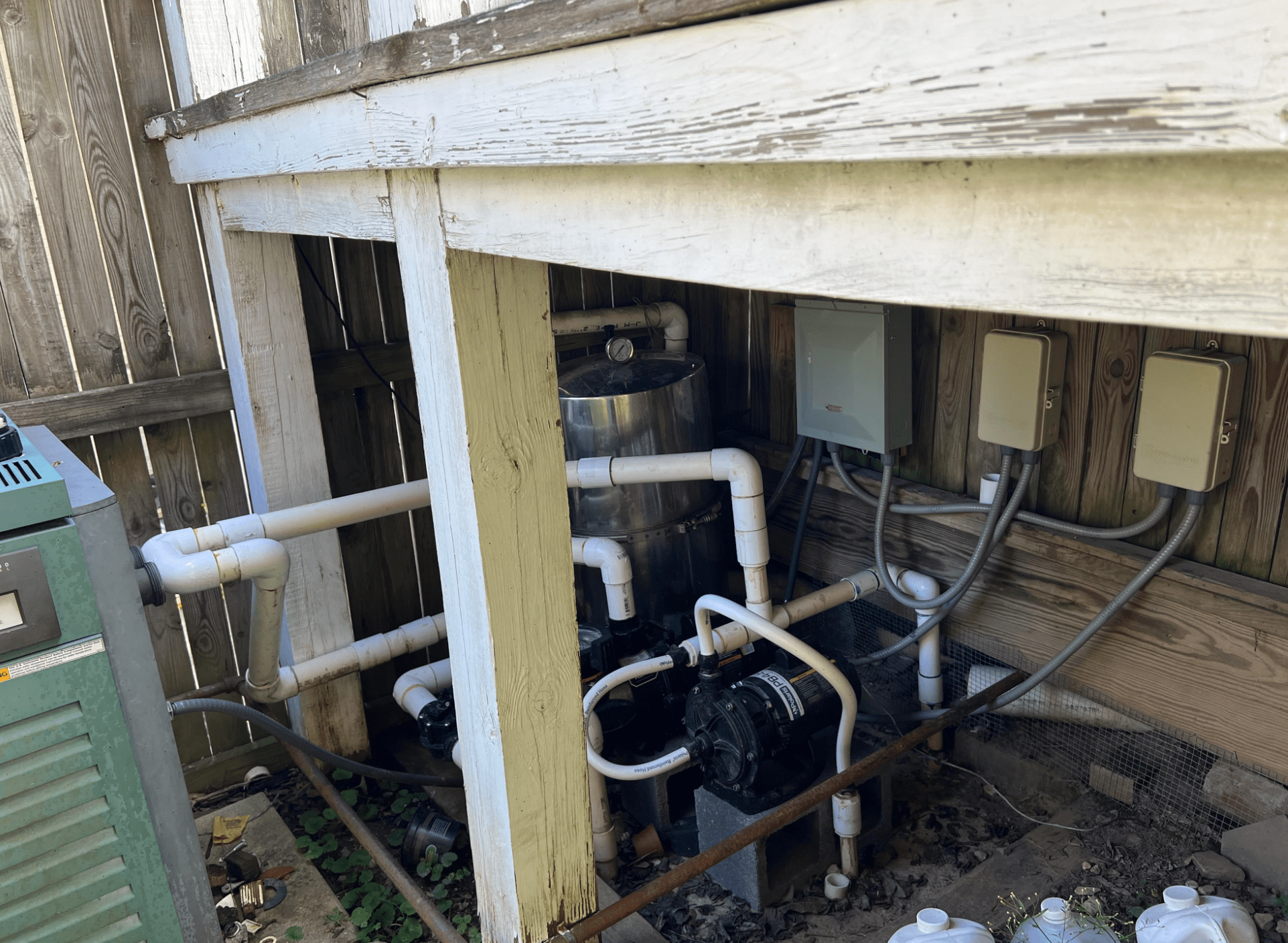

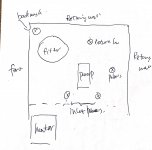

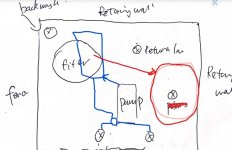

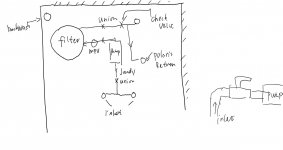

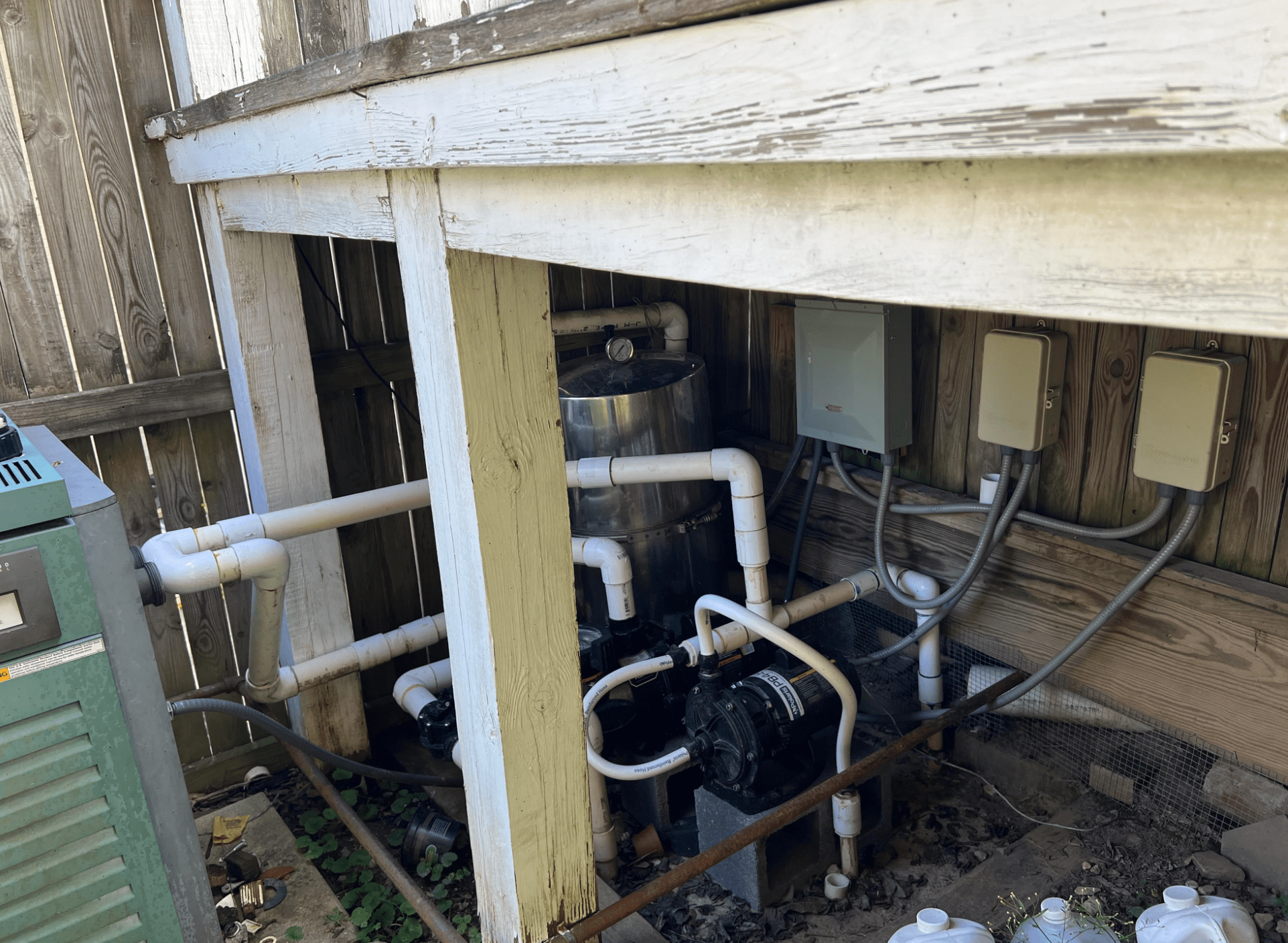

We are converting the ground level deck into a paver patio and during the process we decided to tear down this pool equipment shed and removed the gas line that were underneath the deck (pool heater was dead and we may consider that later with above ground gas line). So now we have about an extra foot behind the DE filter and no height restriction, I would like to get some suggestions from you guys about replumbing and better location of the equipment overall. Hopefully I could use my general contractor to do this before the pool opening.

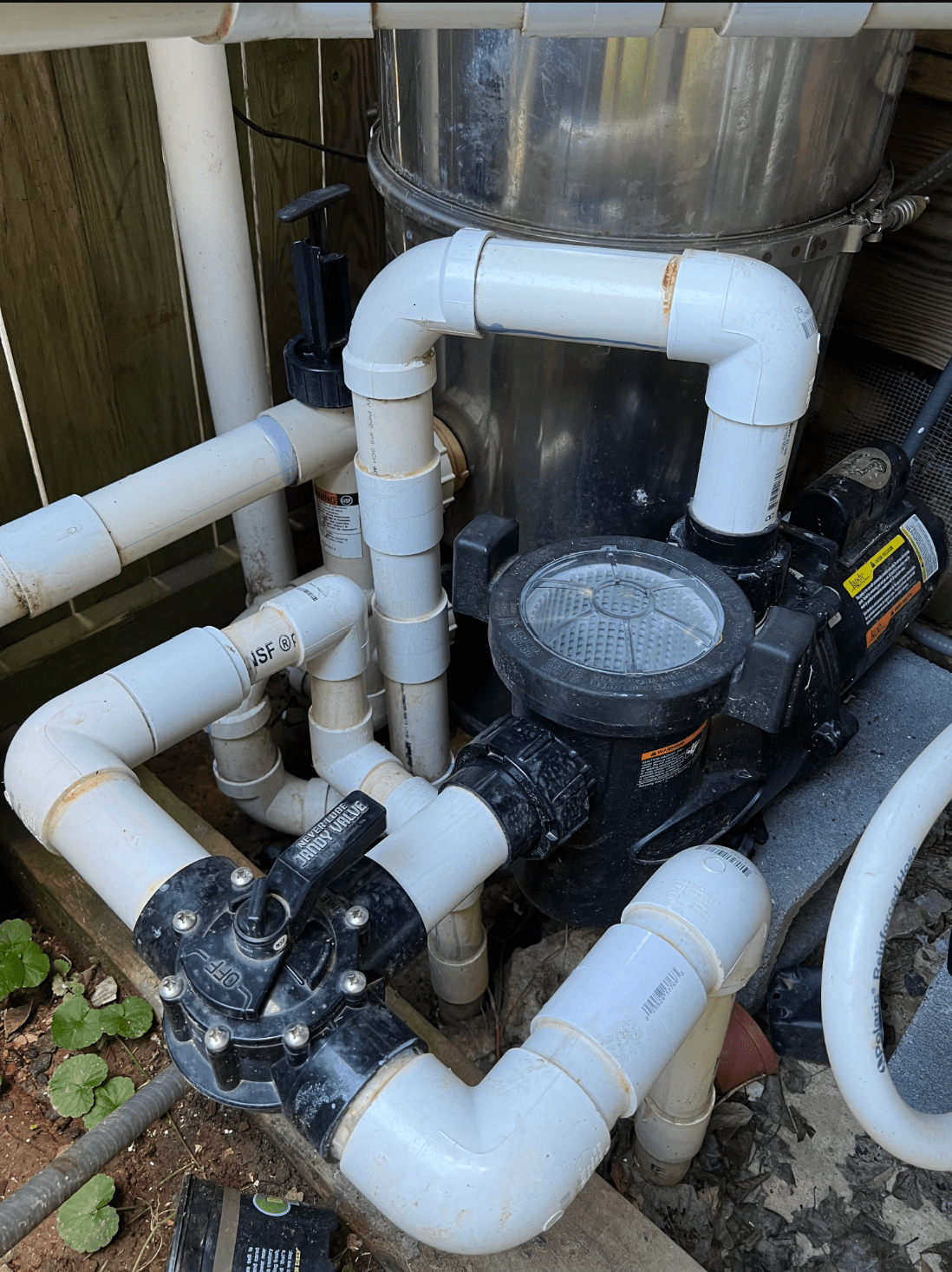

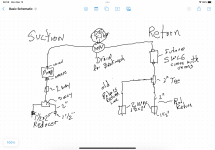

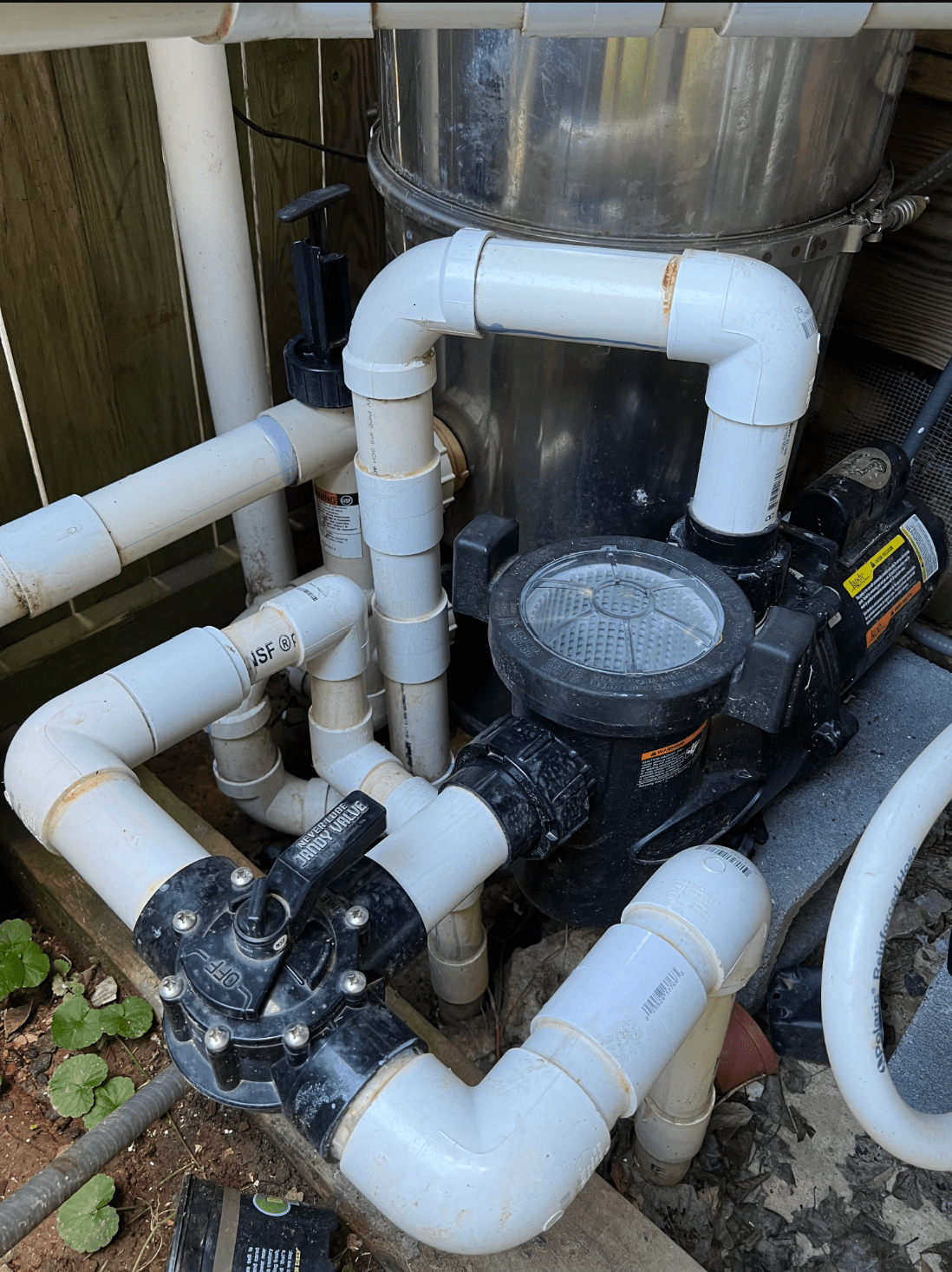

Currently, we have two inlet pipes (one for each skimmer), one return pipe at the far end of the picture. A booster pump hooked in but not in use as I've been using dolphin, so plan to remove it and may just use the booster outlet as an extra return? The DE filter needs to be changed for a newer one (got another Pentair DE for cheap, but the inlet/outlet pipe height is different from the current version). Plan to switch to MPV to replace the slide valve, also add some check valve type at the return line. The pool equipment are lower than the water level.

Pool heater is not in service so we can remove if space is needed. I quoted around a few local pool companies last year (before the patio project, so we still had the shed) and they were all very disliking that shed and said to move filter out from it entirely) but now that there is no such structure and open with a little more room, I would prefer to get the filter still in the corner if possible. There are parts that were not pool grade so schedule 40 pipes all the way for sure.

I will post a few more recent pix later (without the shed now), but would like to pick your brain about the ideas.

Thanks a lot.

Currently, we have two inlet pipes (one for each skimmer), one return pipe at the far end of the picture. A booster pump hooked in but not in use as I've been using dolphin, so plan to remove it and may just use the booster outlet as an extra return? The DE filter needs to be changed for a newer one (got another Pentair DE for cheap, but the inlet/outlet pipe height is different from the current version). Plan to switch to MPV to replace the slide valve, also add some check valve type at the return line. The pool equipment are lower than the water level.

Pool heater is not in service so we can remove if space is needed. I quoted around a few local pool companies last year (before the patio project, so we still had the shed) and they were all very disliking that shed and said to move filter out from it entirely) but now that there is no such structure and open with a little more room, I would prefer to get the filter still in the corner if possible. There are parts that were not pool grade so schedule 40 pipes all the way for sure.

I will post a few more recent pix later (without the shed now), but would like to pick your brain about the ideas.

Thanks a lot.