A year ago I had a Raypak 8450ti heat pump installed. I already had a Hayward propane heater. I wanted to keep both heaters so that I could use the heat pump in the warmer months and use the propane in the winter. We are in Arizona so the winters are mostly mild.

The installer changed the plumbing so that instead of bypassing the heater and returning directly to the pool it now either flows through the Raypak or through the Hayward. This resulted in lowered pressure at the caretaker valve for my infloor cleanning and a dirty pool. So to compensate I increased the rpms of my Pentair Intelliflo VSP to 3000. The caretaker was staying between 14-16 and the floor was getting clean. Unfortunately this pushed the pump too hard and the pump failed and had to be rebuilt. I am trying to find the perfect amount of rpms for the caretaker but I also would like to change the plumbing and reduce the head loss at the equipment. I have reached out to multiple companies and no one is interested in reworking the plumbing, so I am going to DIY.

I have a Pentair EasyTouch 4 for automation.

The pool is 15' X 30', so roughly 15,000gal.

I have ordered replacement popups made by Blue Square Mfg. They are supposed to require less pressure to get the popup to fully extend.

Here is the new pump schedule.

6AM - 10AM = 2750 rpms for cleaning

10AM - 6PM = 1850 rpms for turning over the pool

I am hoping with this new schedule, the new popups and the reconfiguration of the plumbing I will reduce my electricity bill and increase the life of my equipment.

What are your thoughts? Any advice is appreciated. Thank you in advance.

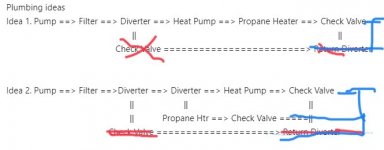

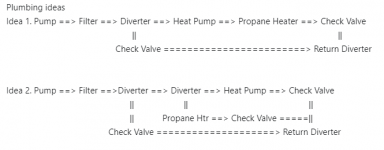

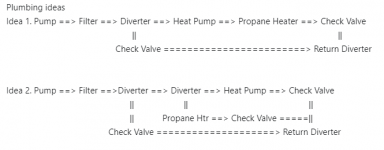

My existing equpment plumbing:

The installer changed the plumbing so that instead of bypassing the heater and returning directly to the pool it now either flows through the Raypak or through the Hayward. This resulted in lowered pressure at the caretaker valve for my infloor cleanning and a dirty pool. So to compensate I increased the rpms of my Pentair Intelliflo VSP to 3000. The caretaker was staying between 14-16 and the floor was getting clean. Unfortunately this pushed the pump too hard and the pump failed and had to be rebuilt. I am trying to find the perfect amount of rpms for the caretaker but I also would like to change the plumbing and reduce the head loss at the equipment. I have reached out to multiple companies and no one is interested in reworking the plumbing, so I am going to DIY.

I have a Pentair EasyTouch 4 for automation.

The pool is 15' X 30', so roughly 15,000gal.

I have ordered replacement popups made by Blue Square Mfg. They are supposed to require less pressure to get the popup to fully extend.

Here is the new pump schedule.

6AM - 10AM = 2750 rpms for cleaning

10AM - 6PM = 1850 rpms for turning over the pool

I am hoping with this new schedule, the new popups and the reconfiguration of the plumbing I will reduce my electricity bill and increase the life of my equipment.

What are your thoughts? Any advice is appreciated. Thank you in advance.

My existing equpment plumbing: