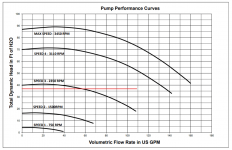

the pump speed is level 3- 2495 RPM with 12 psi at the filter.

If we estimate the total head loss at 37 feet, the flow should be over the minimum of 40 gpm.

So, I suspect that the pump speed is fine.

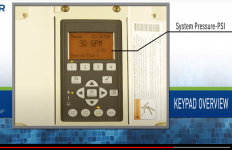

Can you check the pump system pressure, flow in GPM, watts and rpm from the keypad display?

You might need to put the automation into Service mode to make the pump work from the keypad.