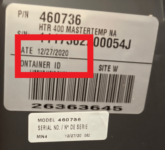

I have a pentair Master temp 400 that stopped working a few months ago. I took the cover off and found a minor leak coming from the water pressure sensor on top of the manifold. It was just enough leak to keep things wet without ever puddling at the bottom and since it is covered it was never detected. I took the wires off the water pressure switch and discovered it was screwed in not even finger tight. I turned it two complete turns by hand and the leak stopped. In the one picture you can see the rusted bolts on the right side and where I had to replace the gas flow switch which is what made it stop working in the first place.

I contacted pentair even though it was out of warranty because this was clearly not installed properly. After several email arguments with the rep who kept insisting I should have contacted them earlier and me telling them it was not evident until the heater stopped working, and him referring me to his supervisor, pentair basically said tough luck. I am very disappointed in pentair not standing behind their product with something that was so obviously not installed properly. Needless to say, when I do have to eventually replace it it will not be with pentair. End of rent against pentair

I was able to get the bolts out, ordered a seal kit, and took the manifold off. The other picture is what it looked like underneath the manifold. I am obviously going to remove all of the rust and clean it all up before putting it back together as well as replacing all of the bolts with stainless steel. My question is should I paint or cold galvanize this area to keep it from rusting again? I do not know how hot this particular area gets and what would be the best way to protect it. Also is there anything else I should be checking, cleaning, etc. before putting it back together. Finally, the bolts did not seem very tight. Does anyone know the torque setting when the bolts are reinstalled?

Thank you for listening and I appreciate the help.

I contacted pentair even though it was out of warranty because this was clearly not installed properly. After several email arguments with the rep who kept insisting I should have contacted them earlier and me telling them it was not evident until the heater stopped working, and him referring me to his supervisor, pentair basically said tough luck. I am very disappointed in pentair not standing behind their product with something that was so obviously not installed properly. Needless to say, when I do have to eventually replace it it will not be with pentair. End of rent against pentair

I was able to get the bolts out, ordered a seal kit, and took the manifold off. The other picture is what it looked like underneath the manifold. I am obviously going to remove all of the rust and clean it all up before putting it back together as well as replacing all of the bolts with stainless steel. My question is should I paint or cold galvanize this area to keep it from rusting again? I do not know how hot this particular area gets and what would be the best way to protect it. Also is there anything else I should be checking, cleaning, etc. before putting it back together. Finally, the bolts did not seem very tight. Does anyone know the torque setting when the bolts are reinstalled?

Thank you for listening and I appreciate the help.